Winding wire of high-temperature-resistance electromagnetic coil and manufacturing method of winding wire

A technology of electromagnetic coil and manufacturing method, applied in cable/conductor manufacturing, circuits, insulated cables, etc., can solve the problems of only about 200 °C, increase the maintenance cost of nuclear power plants, cannot directly meet the operating conditions of nuclear power plants, etc., and achieve high tensile strength. , The effect of improving adhesion and contact tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

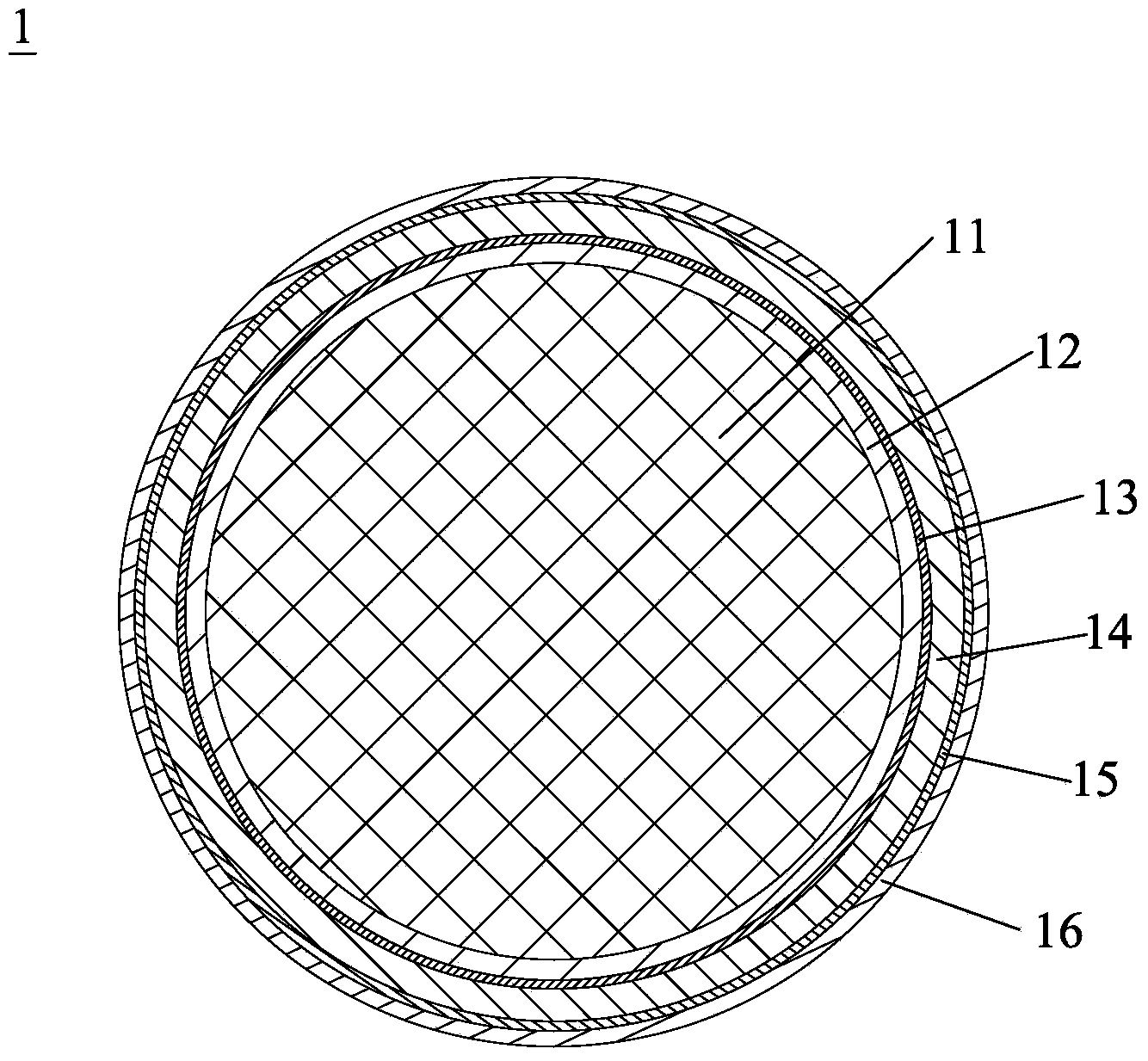

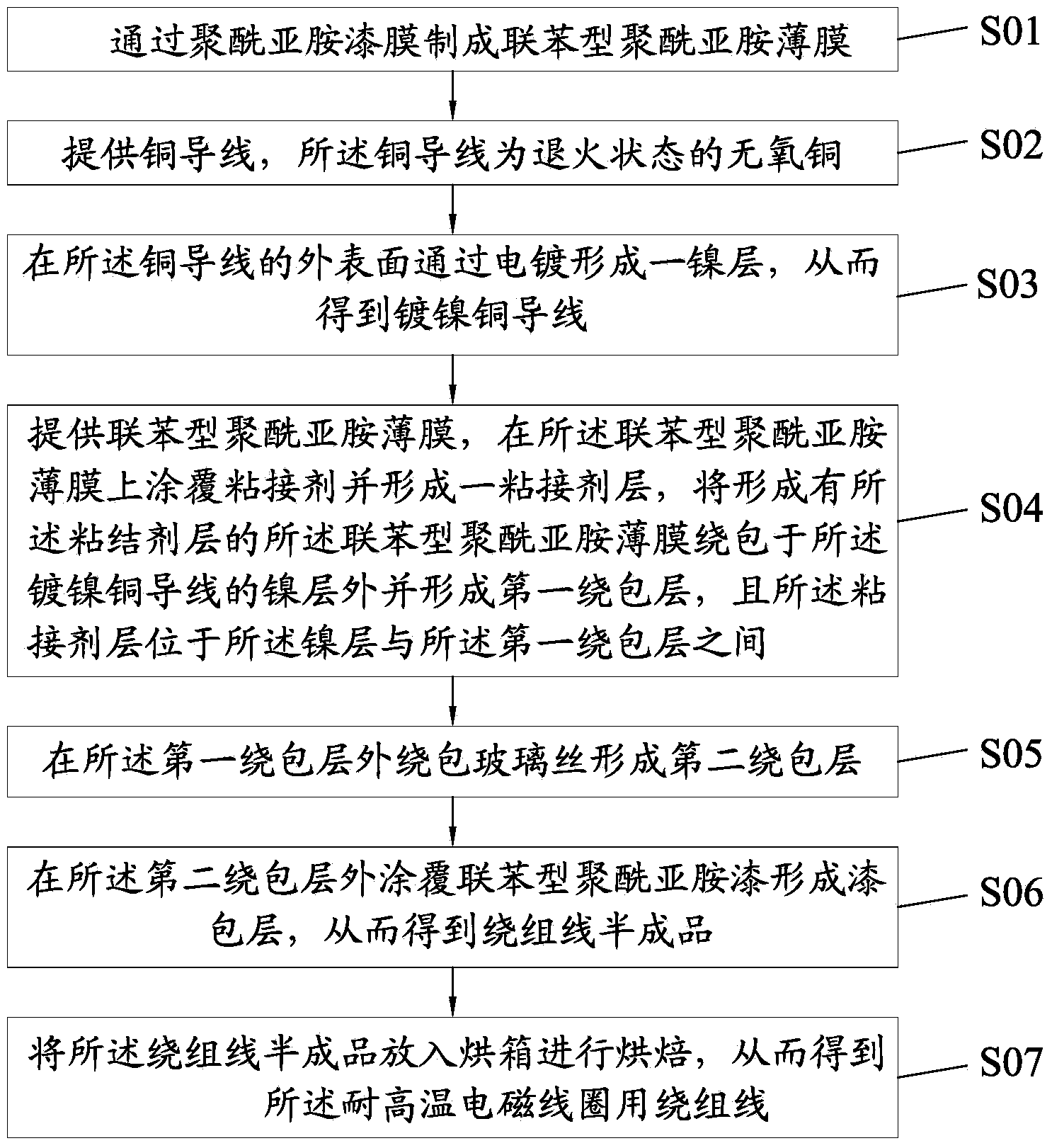

[0038] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. The winding wire 1 for the high temperature resistant electromagnetic coil provided by the present invention enables the rod position driving electromagnetic coil of the control rod driving mechanism to be used stably for a long time in a high temperature environment of about 320°C after the ventilation and cooling system of the nuclear power plant is cancelled.

[0039] Such as figure 1 As shown, the winding wire 1 for a high temperature resistant electromagnetic coil provided by the present invention includes a copper wire 11, and a nickel layer 12 is formed by electroplating on the outside of the copper wire 11, and an adhesive layer 13 is also provided on the outside of the nickel layer 12. The adhesive layer 13 is wrapped with a layer of biphenyl polyimide film to form a first wrapping layer 14, and the first wrapping ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com