Manufacturing method for nitrogenous grid electrode oxidation layer

A technology of gate oxide layer and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems that cannot effectively improve the NBTI performance of pMOSFET semiconductor devices, reduce the possibility of broken bonds, and improve NBTI Performance, the effect of accelerating stress release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Please refer to figure 1 and figure 2However, it is shown in the prior art that a large number of hydrogen ion trap centers are formed in the gate oxide layer 20 due to the implantation of nitrogen ions, which increases the fixed positive charges, leading to the enhancement of the NBTI effect. And a large number of Si-H bonds and S-O-H bonds and Si-SiO bonds are generated during the ISSG process 2 Broken bonds occur near the interface. The PNA high-temperature annealing process used in the prior art is used to stabilize the distribution of N ions and repair the plasma damage in the gate oxide layer 20, but the high-temperature annealing process cannot timely and effectively repair the Si-H bond and S-O-H bond and Si-SiO 2 The broken bonds occurring near the interface cannot effectively improve the NBTI performance of pMOSFET semiconductor devices.

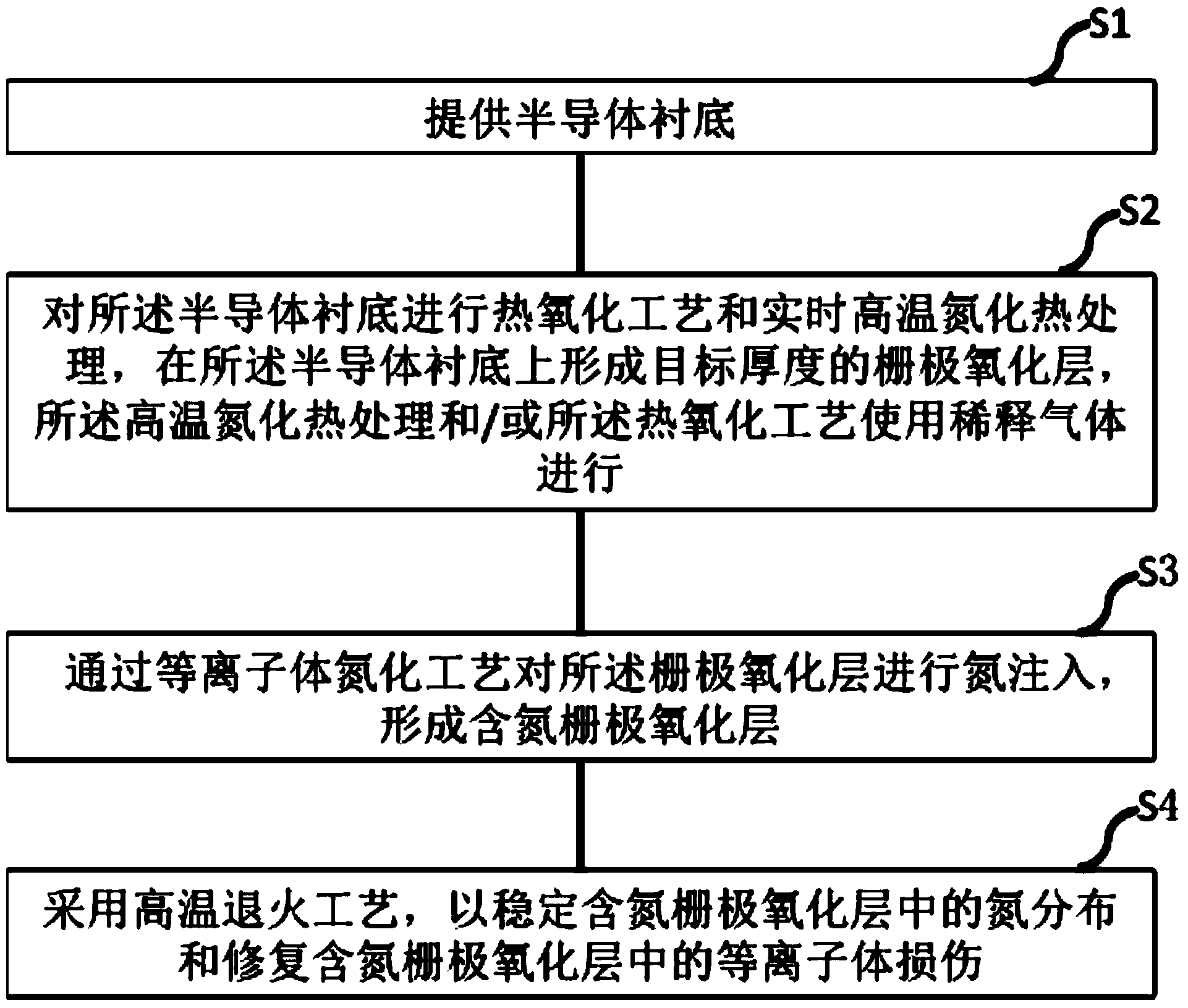

[0040] In order to solve the above problems, the present invention provides a method for manufacturing a nitrogen-co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com