Half-dry and refreshed fish noodles and production process thereof

A production process, fish noodle technology, applied in application, food preparation, food science and other directions, can solve problems such as not meeting consumer demand, and achieve the effect of retaining flavor and taste, convenient to carry and eat, and environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

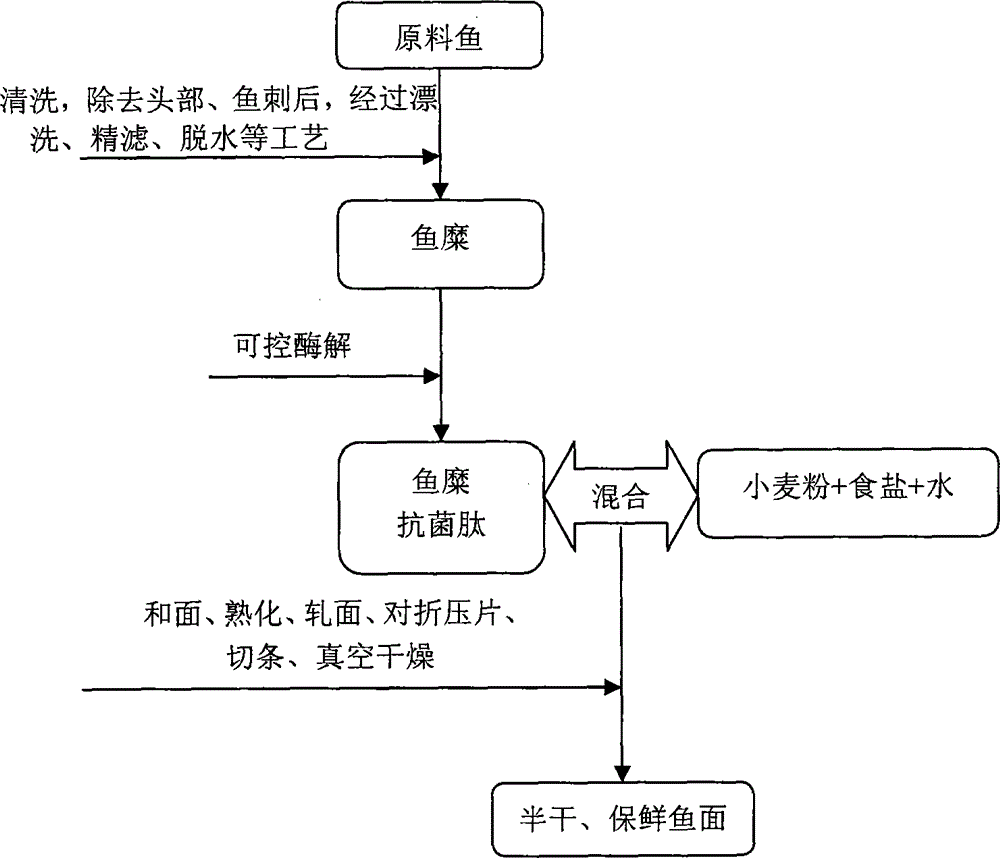

Image

Examples

Embodiment example 1

[0017] The preparation of implementation case 1 surimi antimicrobial peptide

[0018] Wash the fish meat bought in the market, remove the fishbone, rinse, fine filter, dehydrate, finely chop and mix, and add physiological saline to the obtained minced fish, and mix it at a ratio of 1:6 to 1:20. Finally, it is made into surimi solution. Using the surimi solution as the substrate for enzymolysis reaction, use alkaline protease, neutral protease, compound protease, flavor protease and papain to enzymolyze the surimi solution, at pH 6.0-9.0, at 37-70°C , hydrolyzed for different times (0.5-2h), after obtaining the hydrolyzate, adjust the pH to 6.8-7.6, and inactivate the enzyme in a water bath at 90-110°C for 10 minutes, freeze-dry, redissolve into a 1mg / mL sample solution, and make Antibacterial ability test, find out the component with the strongest antibacterial ability, freeze-dry.

Embodiment example 2

[0019] Implementation case 2 Production of semi-dried and fresh fish noodles

[0020] The component (5~40g) with the strongest antibacterial ability obtained in Example 1 is mixed with flour, salt and water of a certain weight ratio (100:2:35), and then kneading (stirring at slow speed 5~ 15min, stirring at a medium speed for 2-5min), aging for 20-40min, rolling the noodles (at the distance between the rollers 1.5mm, 1.8mm, 2mm, each fold and press the sheet 5-10 times to form a dough sheet with a thickness of 1.5mm) , cut into strips (width is 1mm), after vacuum drying for a certain period of time, half-dried, fresh-keeping fish noodles are obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com