Micro nano silver-based material preparation method and micro nano silver-based material

A technology of micro-nano silver and base materials, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of harmful exhaust gas and waste liquid, uneven particle size distribution, heating reaction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

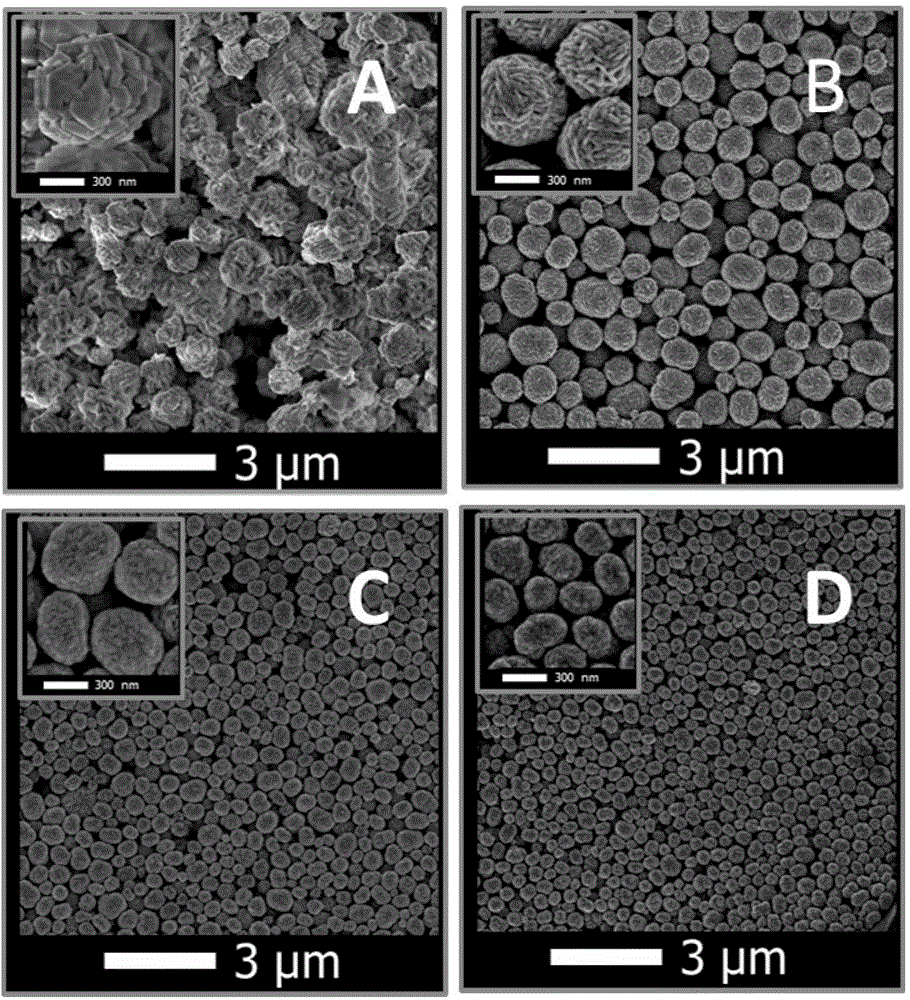

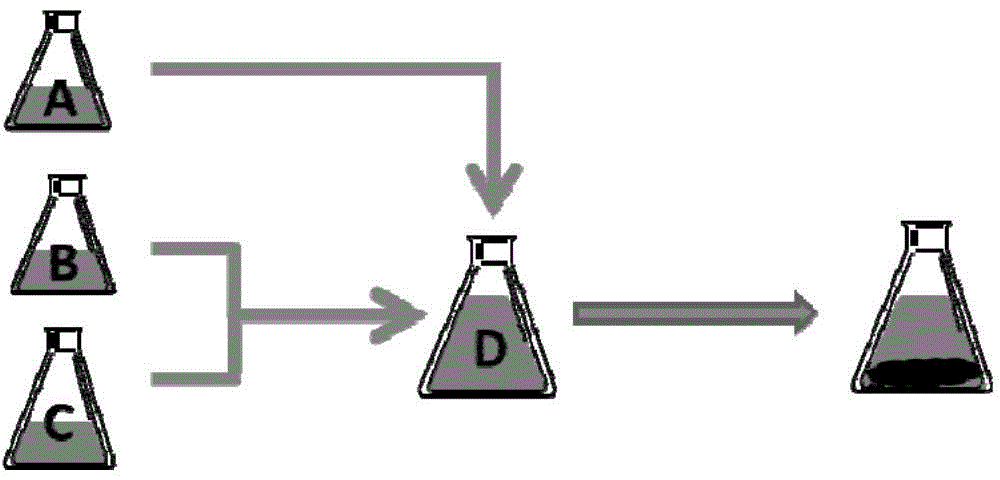

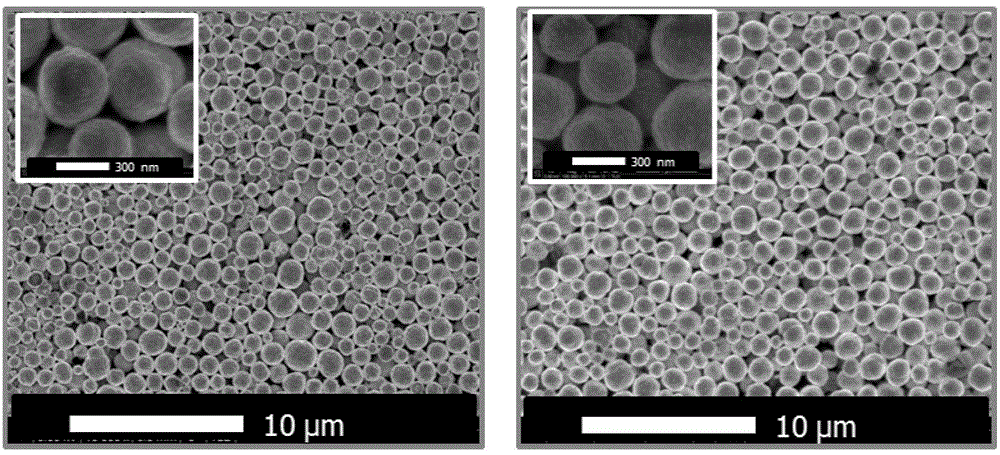

[0039] see figure 2 , the present invention at first provides a kind of synthetic method of micronano silver material, and this method specifically comprises the following steps:

[0040] 1) Dissolve silver nitrate in purified water, and stir in the dark for about 10 minutes (400-800r / min) to obtain silver nitrate solution A, the molar concentration range of which is 0.001-1.0M.

[0041] 2) Dissolve vitamin C in pure water and stir (400-800r / min) to obtain a transparent solution B with a molar concentration range of 0.003-3.0M.

[0042] 3) Dissolving gum arabic in purified water at a concentration of 2-20 wt% (weight percentage), stirring (400-800r / min) until uniform without precipitation, and obtaining gum arabic aqueous solution C.

[0043] 4) While stirring, slowly add solution B to gum arabic aqueous solution C, and continue stirring for 20 minutes until the mixture is evenly stirred to obtain solution D.

[0044] 5) Slowly add silver nitrate solution A to solution D unde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molar concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com