Preparation method of activated carbon adsorbent special for removing heavy hydrocarbon

An activated carbon adsorption, heavy hydrocarbon technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of excessive ineffective pores and insufficient total pore volume, achieve excellent adsorption performance, and realize the miniaturization of the device. , the effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

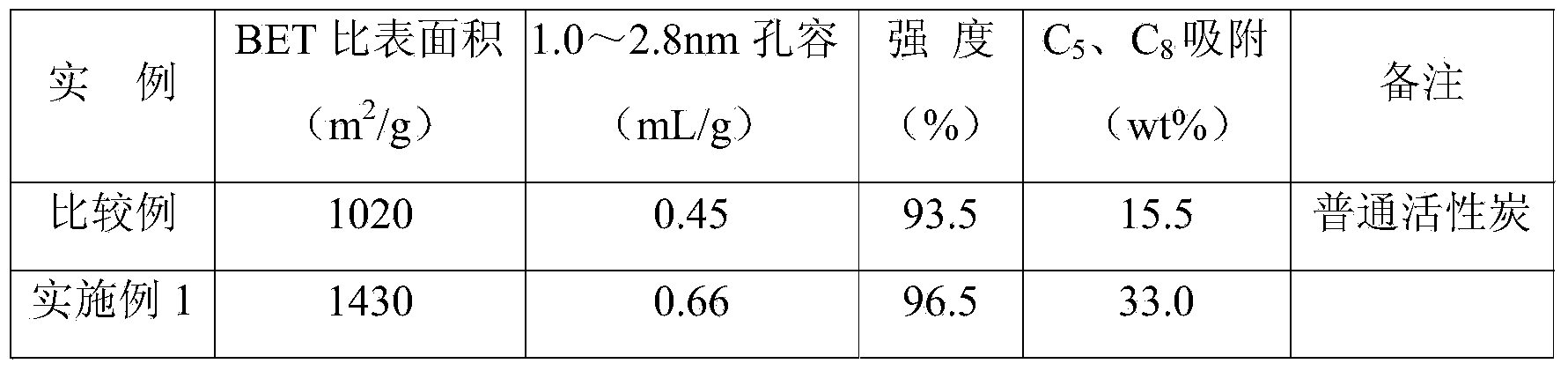

Embodiment 1

[0027] Crush 1000g of anthracite with an ash content less than 3% after dense medium washing to particles less than 8mm, grind it in a ball mill to 200 mesh and pass more than 95%, put it into a kneader, add 250g of coal tar, 60g of coal tar pitch and 60g of water , then add 50g of polyethylene glycol, mix and stir for 50min, press it into Φ4.0mm particles in the extruder, put it in the carbonization furnace after drying and raise the temperature to 550°C for carbonization for 60min, and put the carbonized material in the activation furnace Activation at 920°C for 5hr.

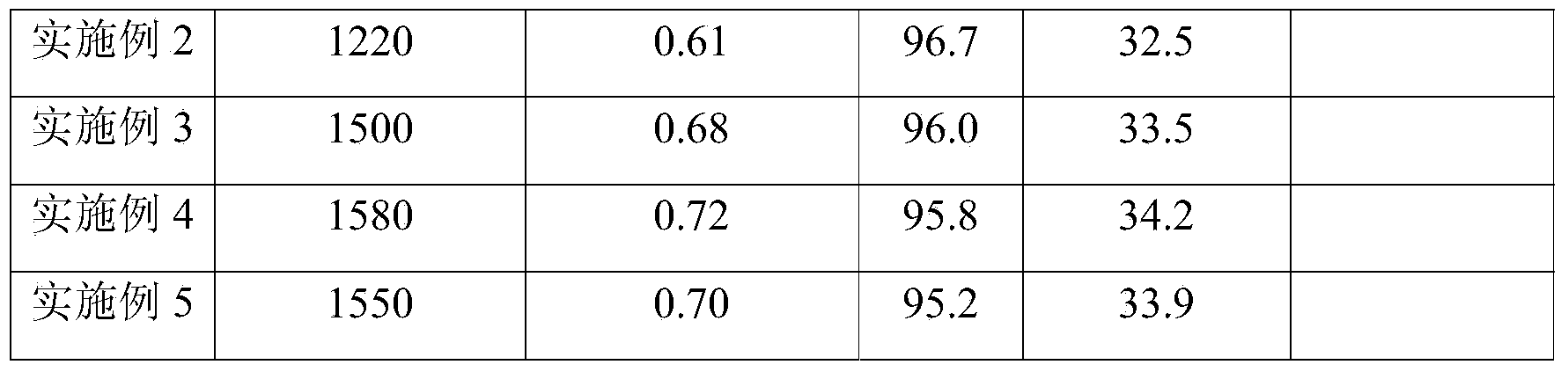

Embodiment 2

[0029] Crush 1000g of anthracite with an ash content less than 3% after dense medium washing to particles less than 8mm, grind it in a ball mill to 200 mesh and pass more than 95%, put it into a kneader, add 250g of coal tar, 60g of coal tar pitch and 60g of water , then add 30g of polyethylene glycol and 70g of dimethyldiamine, mix and stir for 70min, press into Φ4.0mm particles in extruder, dry them, place them in a carbonization furnace and raise the temperature to 560°C for 70min to carbonize The material was activated in an activation furnace at 880°C for 4.5h.

Embodiment 3

[0031] Break 1000g of non-caking bituminous coal with an ash content less than 3% after dense medium washing to particles less than 8mm, grind it in a ball mill to 200 mesh and pass more than 95%, put it into a kneader, add 200g of coal tar, 80g of coal Asphalt and 60g of water, then add 100g of polyethylene glycol, mix and stir for 50min, press into Φ4.0mm pellets in extruder, dry and place in carbonization furnace to heat up to 530°C for 90min and carbonize the material in Activation at 900°C for 5.5h in an activation furnace.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com