Turbid circulating water treatment system for direct reduction iron-making of gas-based shaft furnace

A treatment system, gas-based shaft furnace technology, applied in the field of iron and steel smelting, can solve the problems of lack of turbid ring water treatment system, etc., and achieve the effects of wide application range, obvious cooling effect and water saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

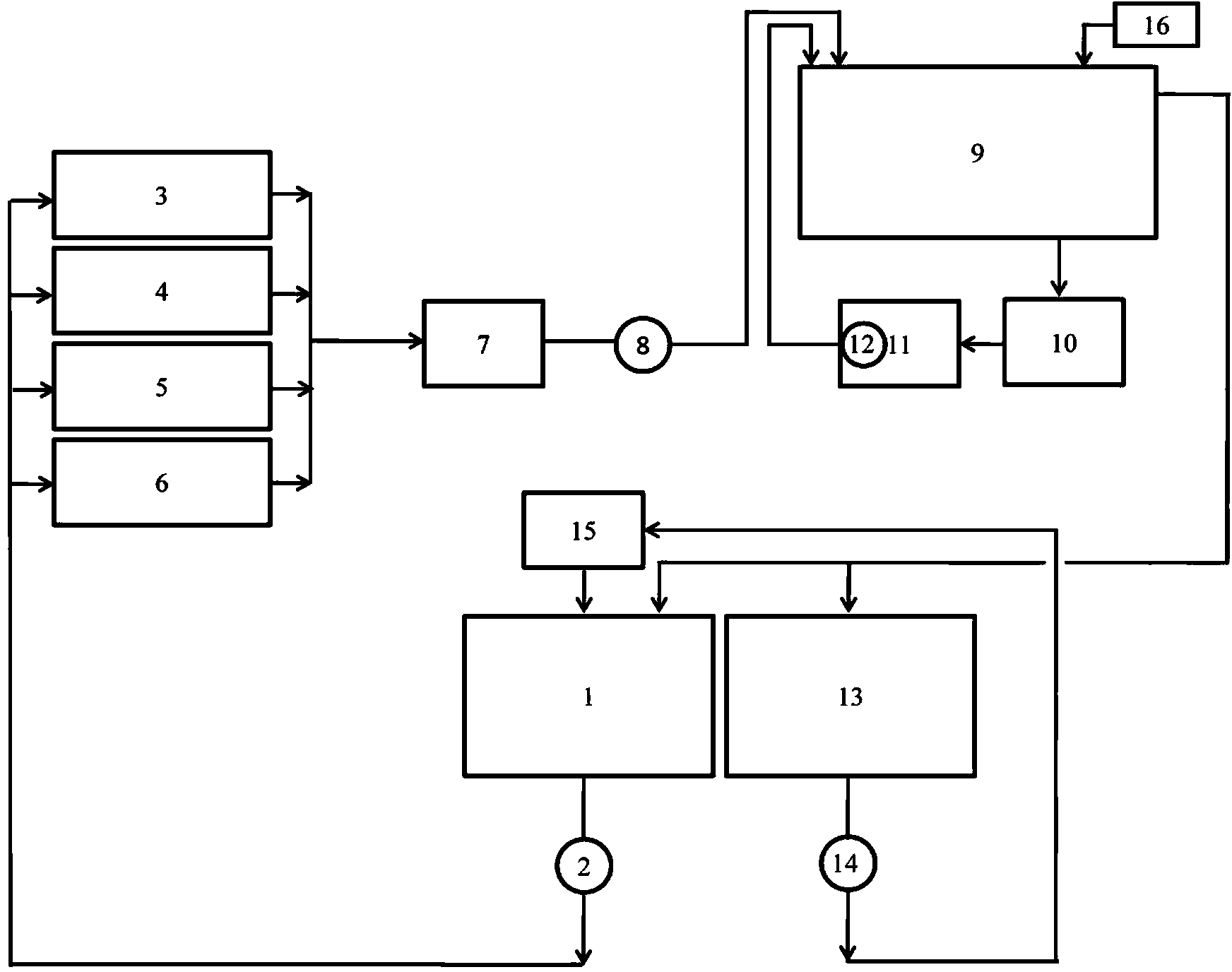

[0025] When the non-catalytic partial oxidation of natural gas is used to produce synthesis gas, the turbid ring water treatment system of the gas-based shaft furnace direct reduction ironmaking process, such as figure 1 shown.

[0026] The turbid ring water treatment system includes a turbid ring water cooling pool, a turbid ring water hot water pool, a central drive concentrator, a cooling tower, a gasification furnace quenching chamber, a gasification furnace water washing tower, a furnace top gas water washing tower and a circulating cooling gas water washing tower , a sludge pool, a platform liquid collection pool, and a sludge collection pool, wherein the turbid ring water cooling pool and the central drive concentrator are connected to the tap water pipe network; the turbid ring water cooling pool is pumped to the Water supply for gasification furnace quenching chamber, gasification furnace water washing tower, furnace top gas water washing tower and circulating cooling...

Embodiment 2

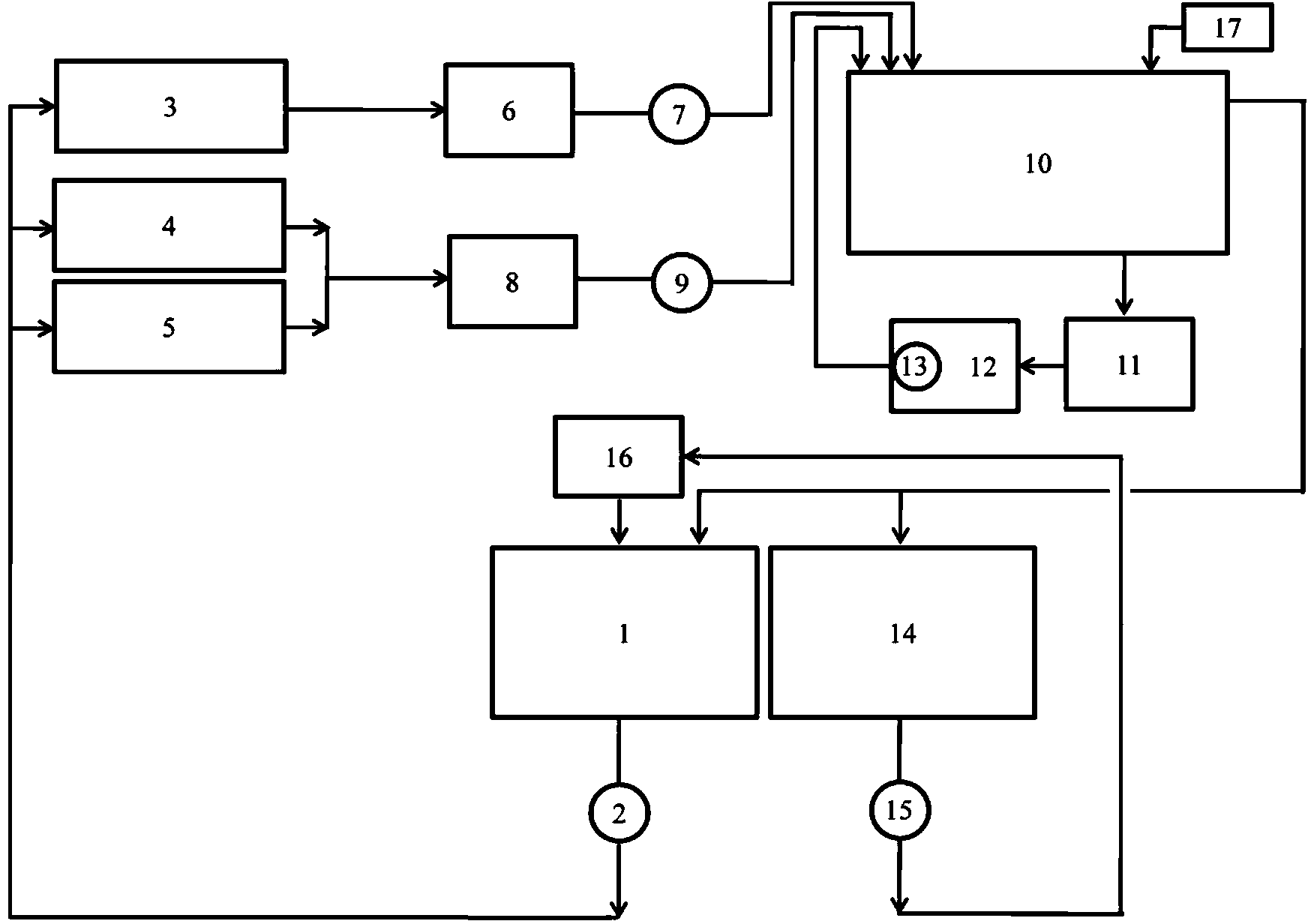

[0034] When pulverized coal gasification is used to produce synthesis gas, the turbid ring water treatment system of the gas-based shaft furnace direct reduction ironmaking process, such as figure 2 shown.

[0035] The turbid ring water treatment system includes a turbid ring water cooling pool, a turbid ring water hot water pool, a central drive concentrator, a cooling tower, a gas generator, a furnace top gas washing tower and a circulating cooling gas washing tower, a sludge pool, and a platform liquid collection pool And the sludge collection tank, wherein, the turbid ring water cooling water tank and the central transmission concentrator are connected to the tap water pipe network; and circulating cooling gas water washing tower; the gasifier, furnace top gas washing tower and circulating cooling gas water washing tower are connected to a plurality of platform liquid sumps; the platform liquid sumps are concentrated with the central drive through the second water pump T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com