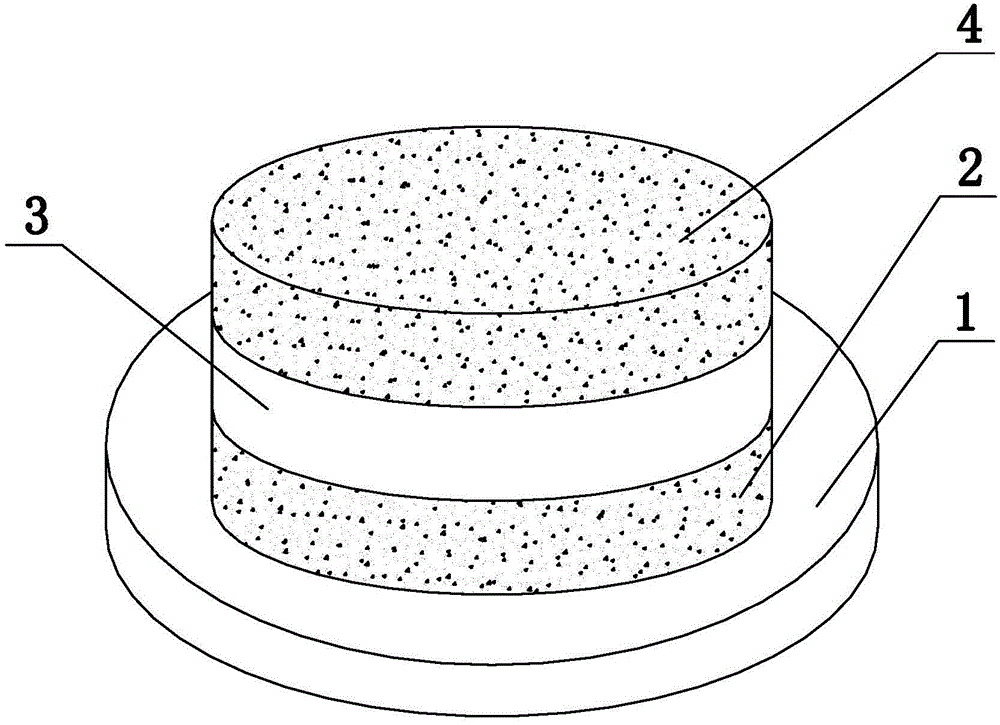

A method for preparing a large-scale carbon/silicon carbide composite heat-insulating bottom plate

A carbon composite material and composite material technology are applied in the field of preparation of large-sized carbon/silicon carbide composite thermal insulation bottom plates, which can solve the problems of carbon material erosion, carbon fiber and matrix carbon fall off of thermal insulation bottom plates, product failure, etc. The effect of shortening manufacturing cycle, improving production efficiency and reducing processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Step 1. According to the shape and performance requirements of the heat insulation floor to be prepared, use conventional methods to make a density of 0.20g / cm by using carbon fiber, carbon cloth and mesh tires 3 carbon fiber preform, and then the carbon fiber preform is densified to a density of 0.80g / cm 3 The carbon / carbon composite material; the method of densification is: carbon fiber prefabricated body is placed in chemical vapor deposition furnace, adopts propylene (also can adopt natural gas or the mixed gas of propylene and natural gas) to carry out chemical vapor phase as carbon source gas Infiltration, the process parameters of chemical vapor infiltration are: the flow rate of carbon source gas is 50L / min, the temperature of chemical vapor infiltration is 900°C, and the holding time is 30h; then the carbon fiber preform after chemical vapor infiltration is placed in an impregnation furnace , carry out furfurone resin pressure impregnation under the condition o...

Embodiment 2

[0034] Step 1. According to the shape and performance requirements of the heat insulation floor to be prepared, use conventional methods to make a density of 0.50g / cm by using carbon fiber, carbon cloth and mesh tires 3 carbon fiber preform, and then the carbon fiber preform is densified to a density of 1.0g / cm 3 carbon / carbon composite material; the method of densification is: carbon fiber prefabricated body is placed in chemical vapor deposition furnace, adopting the mixed gas of propylene and natural gas (also can adopt propylene or natural gas) that the volume ratio is 1:1 Chemical vapor infiltration is carried out as carbon source gas. The process parameters of chemical vapor infiltration are: the flow rate of carbon source gas is 200L / min, the temperature of chemical vapor infiltration is 1100°C, and the holding time is 60h; then the carbon fiber after chemical vapor infiltration The prefabricated body is placed in an impregnation furnace, and the phenolic resin pressure...

Embodiment 3

[0040] Step 1. According to the shape and performance requirements of the heat insulation floor to be prepared, use conventional methods to make a density of 0.40g / cm by using carbon fiber, carbon cloth and mesh tires 3 carbon fiber preform, and then the carbon fiber preform is densified to a density of 0.9g / cm 3 The carbon / carbon composite material; the method of densification is: carbon fiber prefabricated body is placed in chemical vapor deposition furnace, adopts natural gas (also can adopt the mixed gas of propylene or propylene and natural gas) to carry out chemical vapor phase as carbon source gas Infiltration, the process parameters of chemical vapor infiltration are: the flow rate of carbon source gas is 100L / min, the temperature of chemical vapor infiltration is 1000°C, and the holding time is 45h; then the carbon fiber preform after chemical vapor infiltration is placed in an impregnation furnace , carry out pressure impregnation of phenolic resin and furfurone resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com