PVC foam board

A foam board and foam regulator technology, applied in the field of PVC foam board, can solve the problems of unqualified products, waste of time, waste of materials, etc., and achieve the effect of clear proportioning, reasonable method and light material quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

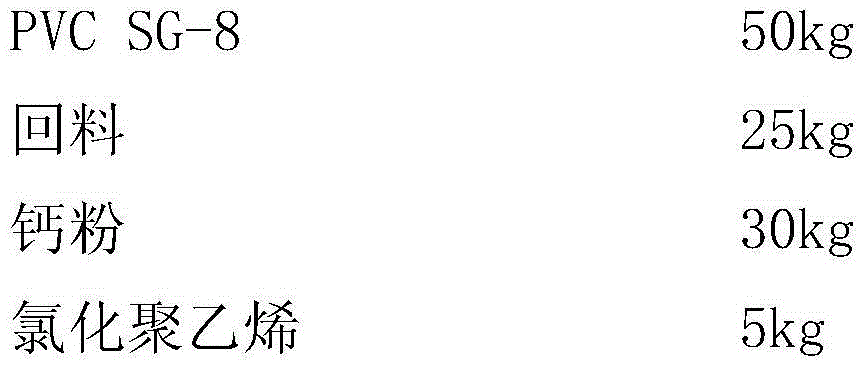

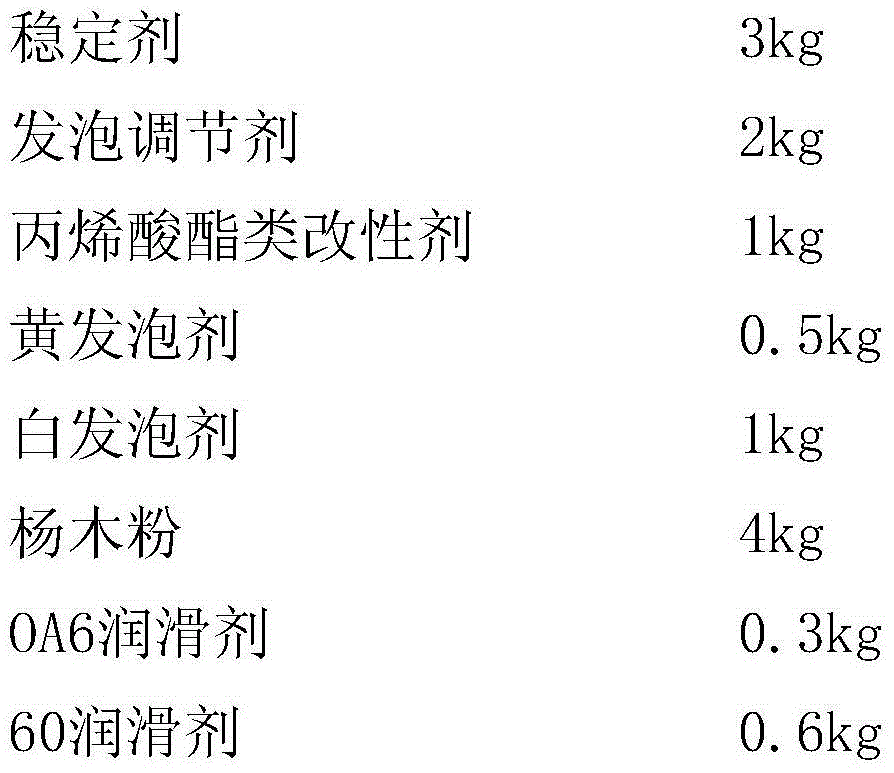

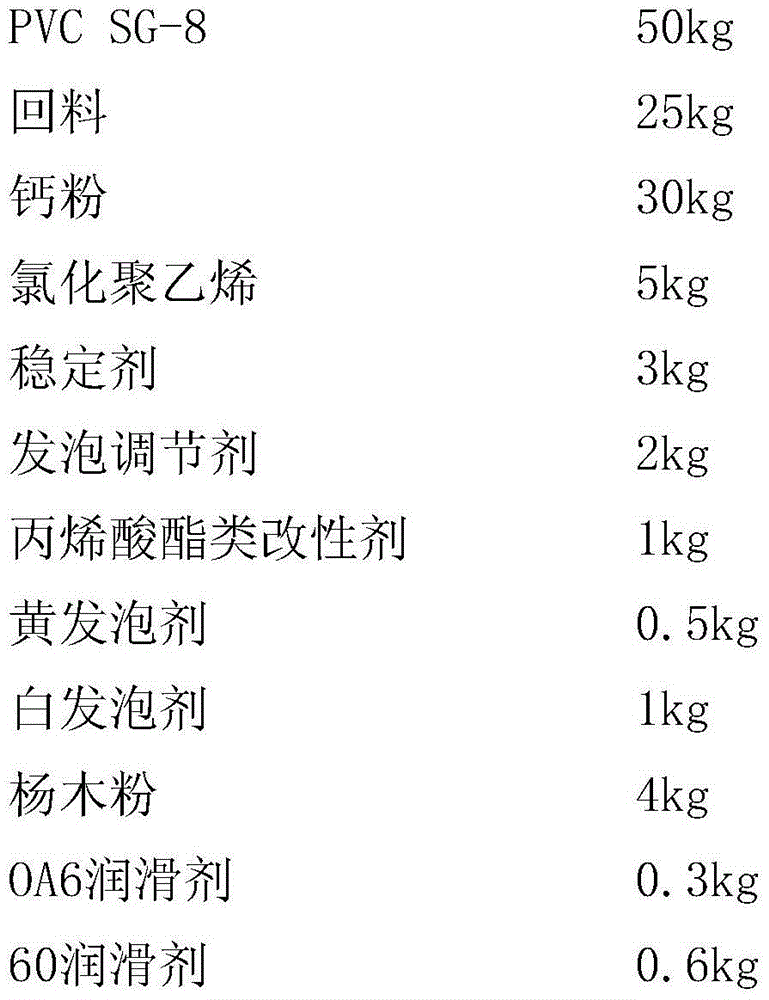

[0021] A PVC foam board, characterized in that: comprising the following components,

[0022]

[0023] The recycled material is one or more of nylon and low-density polyethylene;

[0024] The stabilizer is one of dibasic lead phosphite stabilizer, dibasic lead stearate stabilizer and tribasic lead sulfate stabilizer;

[0025] The foam regulator is an acrylic ester processing aid;

[0026] Described a kind of processing method of PVC foam board, its steps are as follows,

[0027] ①Put PVCSG-8 and recycled materials into a pulverizer to pulverize into powder;

[0028] ② Then PVCSG-8 powder, calcium powder, recycled powder, stabilizer, foam regulator, chlorinated polyethylene, acrylate modifier, white foaming agent, poplar wood powder, OA6 lubricant, yellow hair Put the foaming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com