Silicate blue light fluorescent powder and preparation method thereof

A phosphor and silicate technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problem of low color purity, and achieve the effects of good color rendering, easy promotion, and simple synthesis conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A silicate blue light-emitting phosphor by the expression Gd 4.67 Si 3 o 13 :xBi 3+ , when x = 0.01, weigh Gd 2 o 3 2.1155 g, SiO 2 0.48 g, Bi 2 o 3 0.0012 grams, put it into an agate mortar and grind it thoroughly, put it into a corundum crucible, cover it, and put it in a high-temperature furnace; heat it to 1200°C and keep the temperature constant for 2 hours; then cool it naturally, take it out and grind it, and the body color is white blue light emitting phosphors.

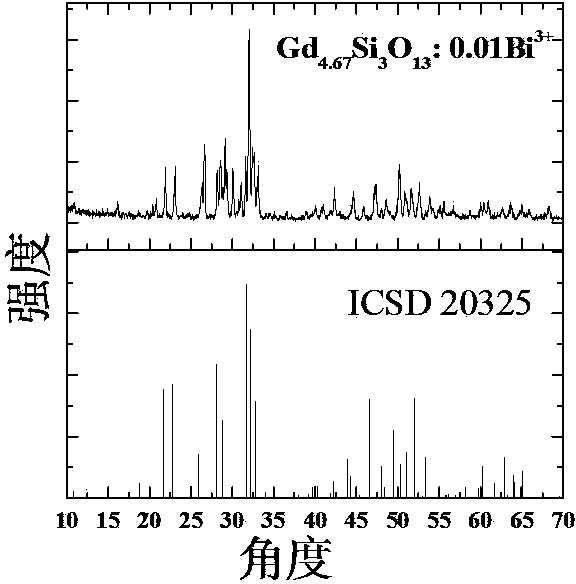

[0027] figure 1 It is the X-ray color atlas of the color-tunable phosphor material of Example 1 of the present invention, by figure 1 It can be seen that the diffraction peak position of the fluorescent material of the present invention is consistent with ISCD20325 in the crystallographic database, indicating that the synthetic fluorescent powder is Gd 4.67 Si 3 o 13 .

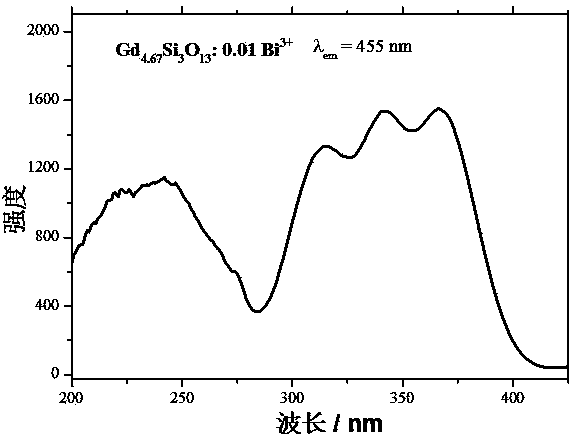

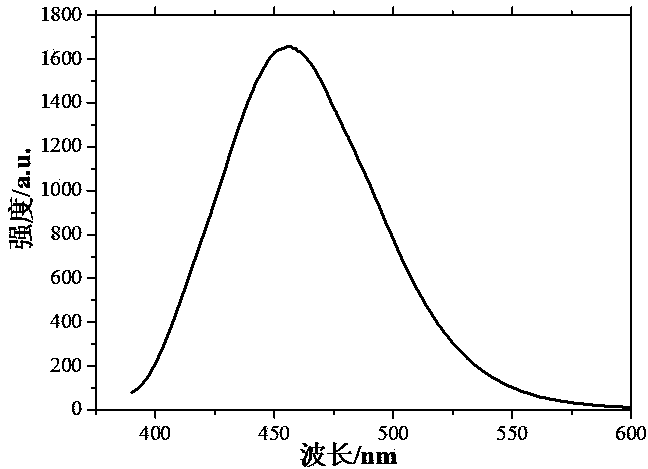

[0028] figure 2 It is embodiment 1 of the present invention Gd 4.67 Si 3 o 13 : 0.01Bi 3+ The excitation spectr...

Embodiment 2

[0031] A silicate blue light-emitting phosphor by the expression Gd 4.67 Si 3 o 13 :xBi 3+ , when x = 0.02, weigh Gd 2 o 3 2.1155 g, SiO 2 0.48 g, Bi 2 o 3 0.0233, put it into an agate mortar and grind it thoroughly, put it into a corundum crucible, cover it, and place it in a high-temperature furnace; heat it to 1250°C and keep the temperature constant for 3 hours; then cool it naturally, take it out and grind it, and the body color is white Blue light emitting phosphor.

Embodiment 3

[0033] A silicate blue light-emitting phosphor by the expression Gd 4.67 Si 3 o 13 :xBi 3+ , when x = 0.03, weigh Gd 2 o 3 2.1155 g, SiO 2 0.48 g, Bi 2 o 3 0.0350 g, put it into an agate mortar and grind it thoroughly, put it into a corundum crucible, cover it, and place it in a high-temperature furnace; heat it to 1350°C and keep the temperature constant for 4 hours; then cool it naturally, take it out and grind it, and the body color is white blue light emitting phosphors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com