Method for determination of material liquid retention ratio in cut cigarette tobacco preparation

A technology of retention rate and feed liquid, which is applied in the field of measuring the retention rate of feed liquid in the process of making cigarette shreds, can solve the problems of difficult work, difficulty in representing various feed liquid monomers with different physical and chemical properties, and difficulty in obtaining flavoring design, etc. Achieve the effect of improving the processing technology, improving the quality and stability of cigarette products, and avoiding objective impossibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

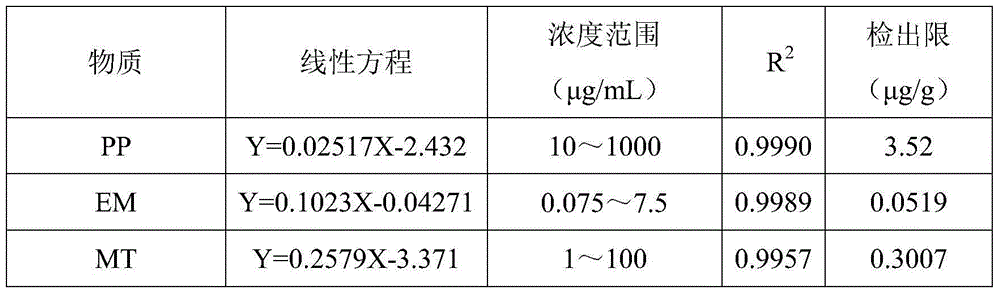

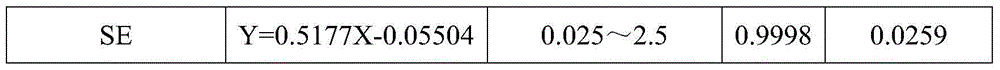

[0033] Example 1 Selection of Markers

[0034] Taking a cigarette shredding sample as the object, take 2 equal parts of unadded tobacco slices, 1 part is used as a blank sample, and the other part is added according to the normal feeding amount. The two samples were subjected to solvent extraction and then analyzed by GC / MS instrument. It was found that some volatile and semi-volatile compounds were added to the tobacco flake samples after feeding. Combined with the analysis results of the unfortified samples, four new substances, including PP, EM, MT, and SE, were added to the tobacco sheet after feeding (wherein PP stands for propylene glycol, EM stands for ethyl maltol, MT stands for menthol, and SE stands for medium in the extract. key ethyl ester). After qualitative identification, it is confirmed that it is the characteristic aroma component in the feed liquid, and its component properties are shown in Table 1 below. The properties and attributes of the four substances...

Embodiment 2

[0037]Example 2: Detection of markers

[0038] (1) Internal standard solution: Accurately weigh 0.2 g of phenethyl propionate, use ethanol as a solvent, dilute to a 100 mL volumetric flask, and shake well to obtain the internal standard stock solution. Accurately pipette 1mL of the internal standard stock solution, use ethanol as a solvent, dilute the volume to a 100mL volumetric flask, and shake well to obtain the internal standard solution.

[0039] (2) Standard working solution: Accurately weigh 10.0g PP, 0.075g MT, 1.0g EM and 0.025g SE, use ethanol as a solvent, dilute to a 100mL volumetric flask, and shake well to obtain a primary standard stock solution. Accurately pipette 1 mL of the primary standard stock solution, use ethanol as a solvent, dilute the volume to a 10 mL volumetric flask, and shake well to obtain the secondary standard stock solution. Accurately pipette 10 μL, 20 μL, 80 μL, 200 μL, 400 μL and 1 mL of the secondary standard stock solution, respectively,...

Embodiment 3

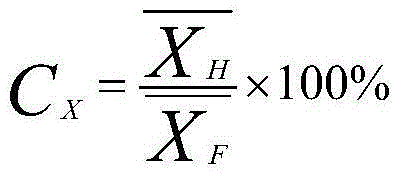

[0047] Example 3: Calculation of Marker Retention

[0048] After the equipment in the silk making and drying process runs smoothly, 30 samples are randomly selected every 1 min from the exit of the process, and each sample is about 20g. Then, the obtained samples were prepared according to the shredding method, that is, the laboratory shredder was started, and the samples were put into the inlet of the shredder and shredded (the shred width was 0.9-1.0 mm). The cut sample is immediately put into a plastic bag, shaken well, and mixed evenly. This is the sample to be tested. The above series of standard working solutions were analyzed by GC / MS, and the instrument conditions were shown in Example 2. Calculate the retention rate of each marker after the drying process according to the following formula:

[0049] C X = X H ‾ X ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ionization potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com