Nitrogen-doped carbon nano-material as well as preparation method and application thereof

A technology of carbon nanomaterials and nitrogen-doped carbon, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of poor cathode oxygen reduction performance, etc., and achieve suitable for large-scale production, improve efficiency, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

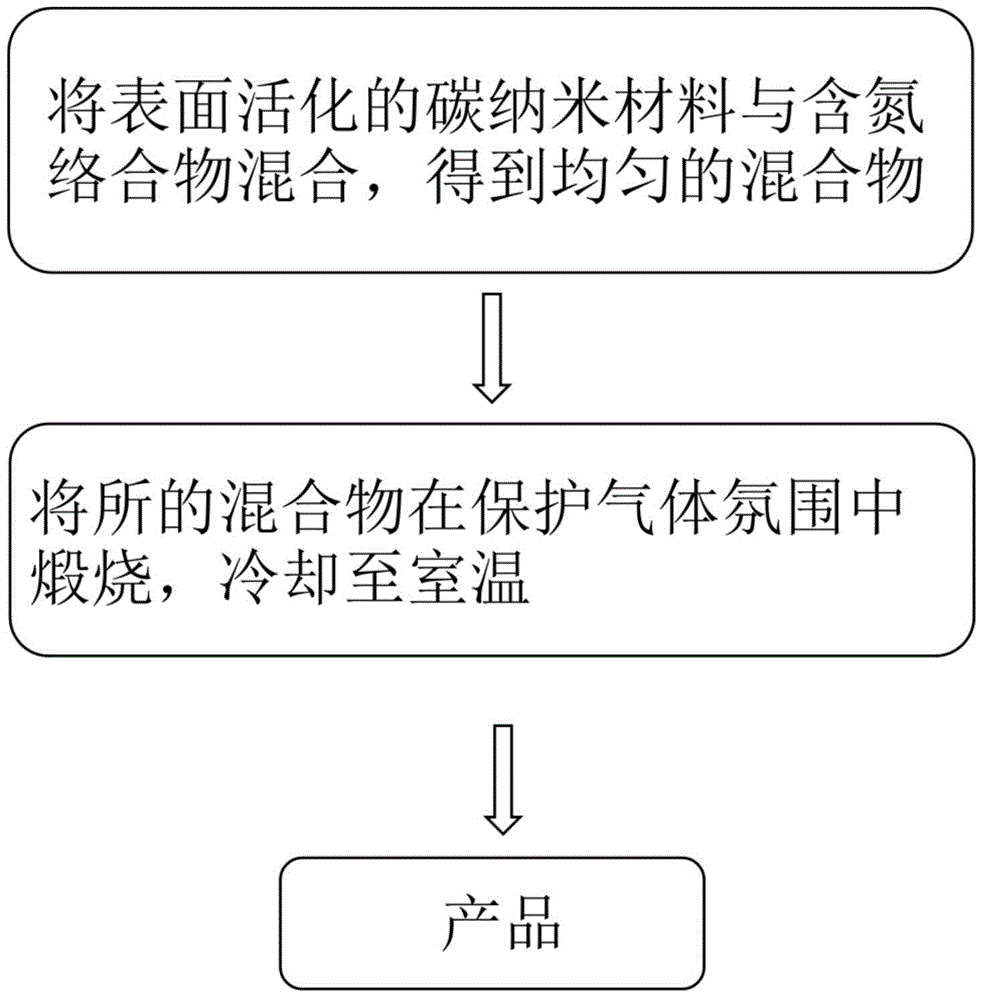

[0034] The nitrogen-doped carbon nanomaterial, its preparation method, such as figure 1 shown, including the following steps:

[0035] (1) Mix the surface-activated carbon nanomaterial and the nitrogen-containing complex uniformly according to a mass ratio of 1:1 to 1:5 to obtain a precursor mixture.

[0036] In order to make the precursor mixture more uniform, it can be mixed as follows:

[0037] (a) adding carbon nanomaterials and nitrogen-containing complexes in a mass ratio of 1:1 to 1:5, adding them into deionized water and stirring thoroughly to obtain a suspension;

[0038] (b) Ultrasonic dispersing the suspension obtained in step (a) for 10 minutes to 30 minutes to make the dispersion uniform.

[0039] (c) Evaporating water from the suspension obtained in step (b) at 50°C to 70°C, then vacuum drying at 40°C to 80°C and grinding into powder to obtain the precursor mixture.

[0040] The surface-activated carbon nanomaterials are acid-treated carbon nanomaterials or gr...

Embodiment 1

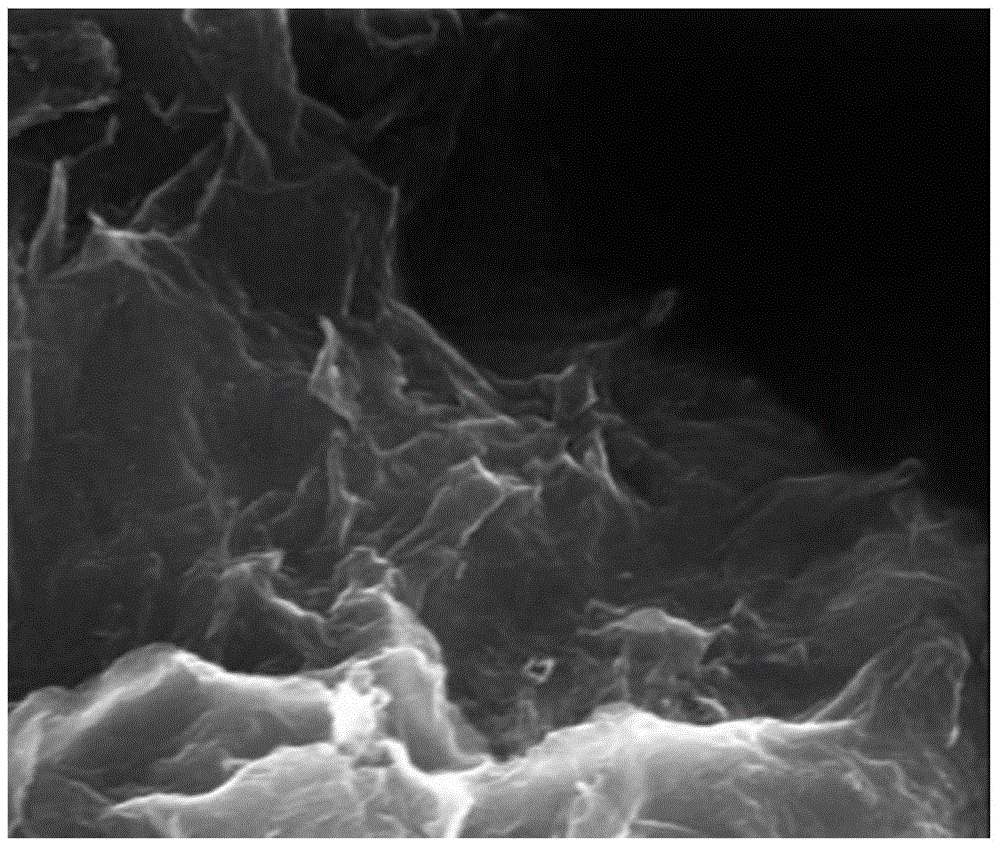

[0050] A nitrogen-doped carbon nanomaterial, electron micrographs as figure 2 As shown, including nitrogen-containing heterocyclic compounds and carbon nanomaterials, wherein the mass content of nitrogen is 2%. The nitrogen existing in the nitrogen-containing heterocyclic compound is pyridine nitrogen, pyrrole nitrogen and graphitized nitrogen. The carbon nanomaterial is graphene oxide.

[0051] The nitrogen-doped carbon nanomaterial is prepared according to the following steps:

[0052] (1) Mix the surface-activated carbon nanomaterials and the nitrogen-containing complex uniformly at a mass ratio of 1:5 to obtain a precursor mixture.

[0053] In order to make the precursor mixture more uniform, it can be mixed as follows:

[0054] (a) adding carbon nanomaterials and nitrogen-containing complexes in a mass ratio of 1:5, adding them into deionized water and stirring thoroughly to obtain a suspension;

[0055] (b) Ultrasonic disperse the suspension obtained in step (a) for 3...

Embodiment 2

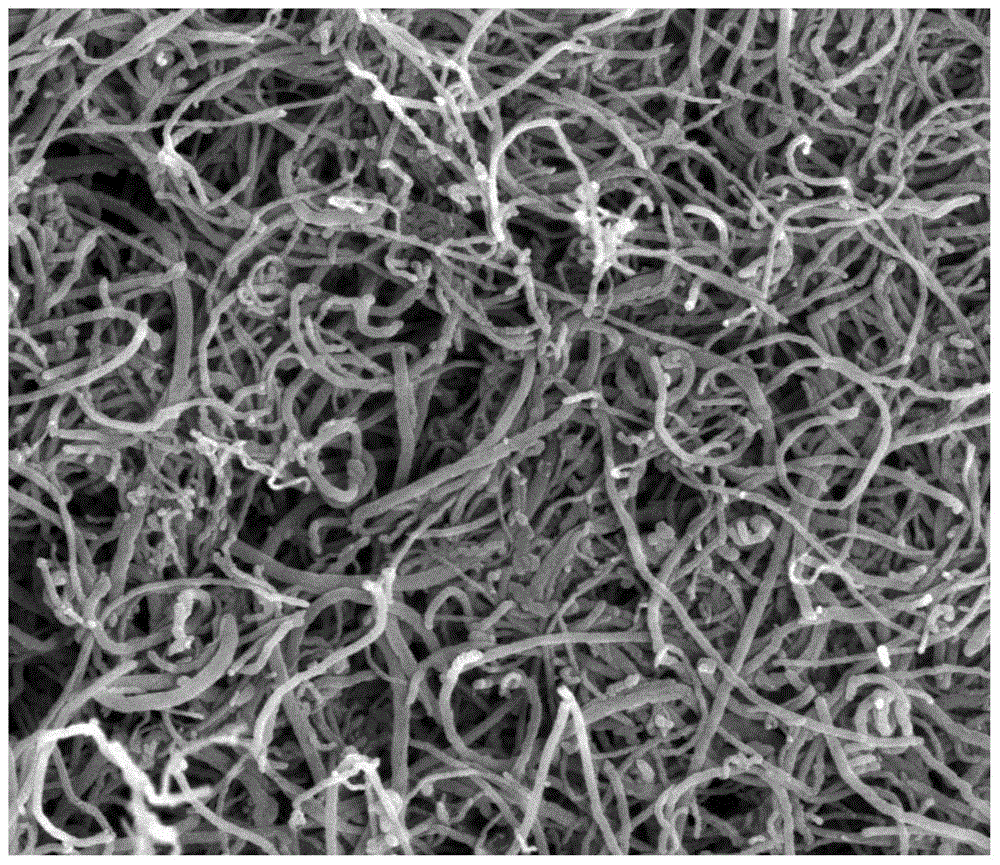

[0061] A nitrogen-doped carbon nanomaterial, electron micrographs as image 3 Shown, including nitrogen-containing heterocyclic compounds and carbon nanomaterials, wherein the mass content of nitrogen is 10.4%. The existence of nitrogen in the nitrogen-containing heterocyclic compound is pyridine nitrogen, pyrrole nitrogen and graphitized nitrogen, and its X-ray photoelectron energy fine spectrum (XPS) is as follows: Figure 4 shown. The carbon nanomaterials are carbon nanotubes.

[0062] The nitrogen-doped carbon nanomaterial is prepared according to the following steps:

[0063] (1) Mix the surface-activated carbon nanomaterials and the nitrogen-containing complex uniformly at a mass ratio of 1:5 to obtain a precursor mixture.

[0064] To make the precursor mixture more uniform, mix as follows:

[0065] (a) adding carbon nanomaterials and nitrogen-containing complexes in a mass ratio of 1:5, adding them into deionized water and stirring thoroughly to obtain a suspension;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com