Method for controlling microbes in algae powder by combination of microwave sterilization and spray drying

A technology of microorganisms and microalgae powder, which is applied in food drying, application, food preparation, etc., and can solve problems such as ineffective effects, poor applicability, and quality changes of algae powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

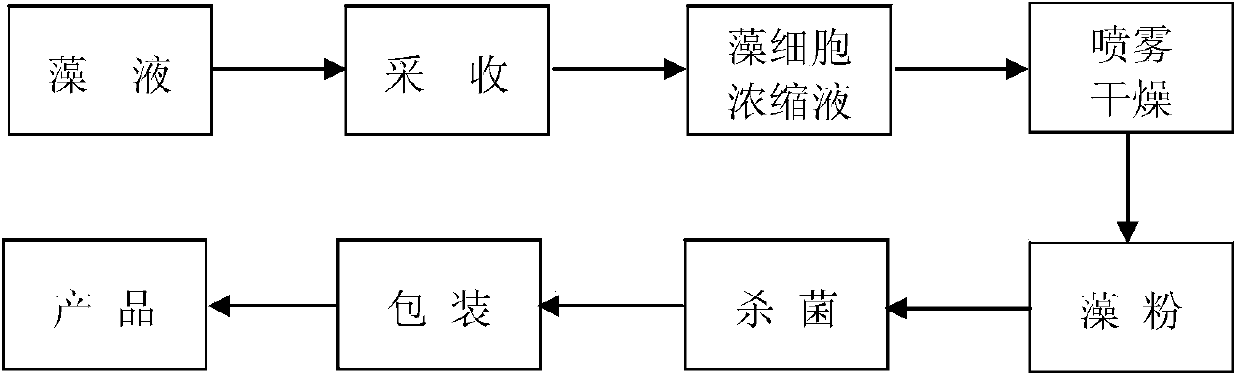

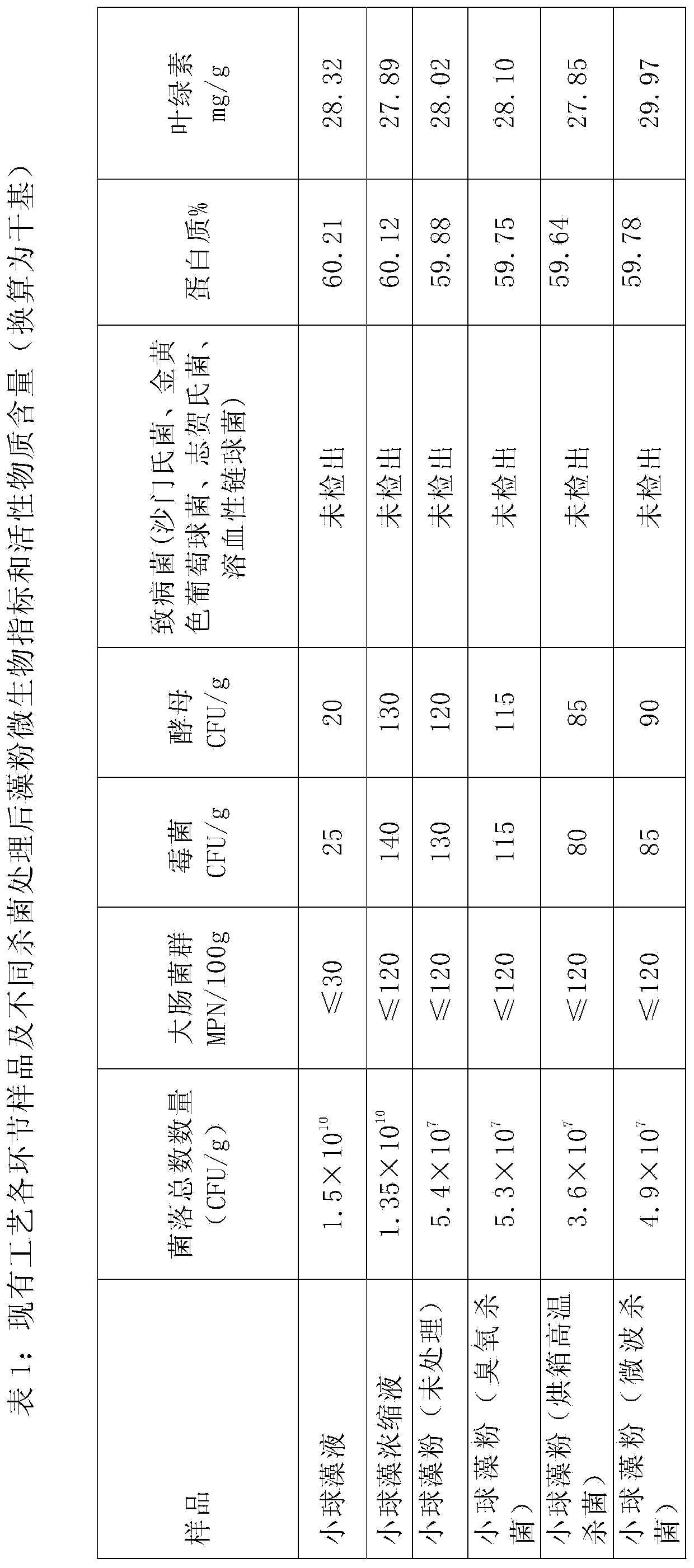

[0054] Embodiment 1: implement sterilization by existing technology

[0055] Proceed as follows:

[0056] (1) The "heterotrophic-dilution-light-induced" technology (see Chinese invention patent: ZL200610025618.9) is used to cultivate the chlorella algae liquid. After determination, the microbial indicators (converted to dry basis) are: the total number of colonies 1.5 × 10 10 CFU / g, coliform group ≤30MPN / 100g, mold 25CFU / g, yeast 20CFU / g, pathogenic bacteria (Salmonella, Staphylococcus aureus, Shigella, hemolytic streptococcus) were not detected;

[0057] (2) Concentrate by centrifugation (5000 rpm, 10 min), and the solid content of the concentrated solution is 14.5% (percentage by weight). After determination, the microbial indicators (converted to dry basis) are: the total number of colonies 1.35 × 10 10 CFU / g, coliform group ≤120MPN / 100g, mold 140CFU / g, yeast 130CFU / g, pathogenic bacteria (Salmonella, Staphylococcus aureus, Shigella, hemolytic streptococcus) were not det...

Embodiment 2

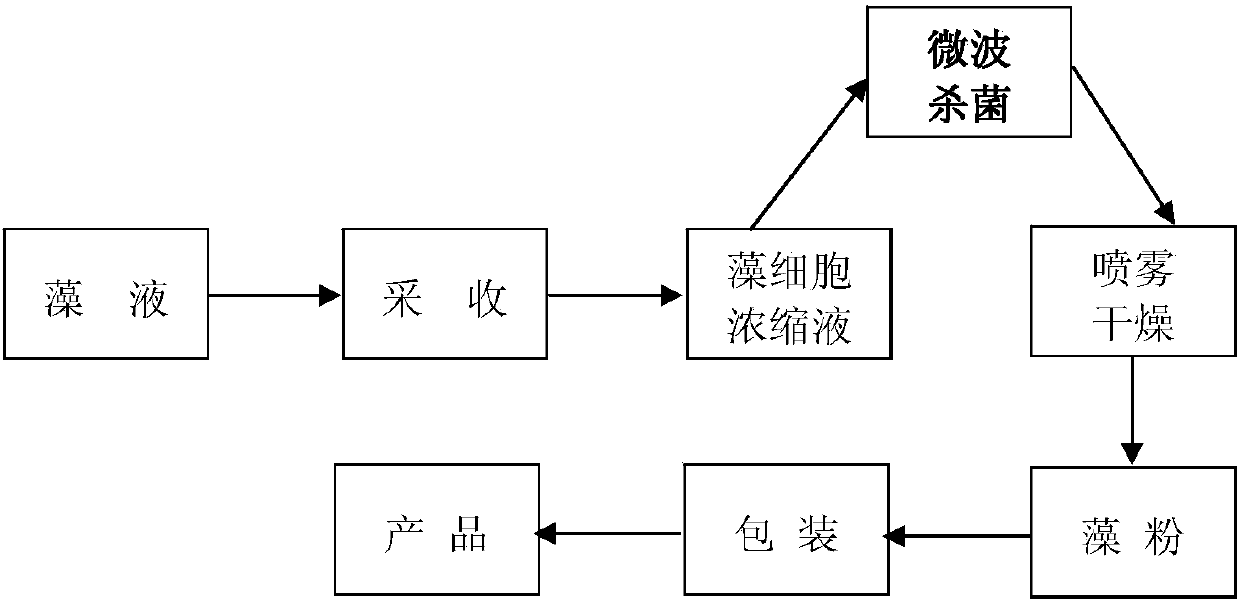

[0065] Embodiment 2: the sterilization implemented by technical scheme of the present invention

[0066](1) According to the "heterotrophic-dilution-light-induced" technology (see Chinese invention patent: ZL200610025618.9) to cultivate the chlorella algae liquid. After determination, the microbial indicators (converted to dry basis) are: the total number of colonies 1.5 × 10 10 CFU / g, coliform group ≤30MPN / 100g, mold 25CFU / g, yeast 20CFU / g, pathogenic bacteria (Salmonella, Staphylococcus aureus, Shigella, hemolytic streptococcus) were not detected;

[0067] (2) Collecting and concentrating the chlorella liquid by centrifugation, and the solid content of the concentrated solution is 14.5% (percentage by weight). After determination, the microbial indicators (converted to dry basis) are: the total number of colonies 1.35 × 10 10 CFU / g, coliform group ≤120MPN / 100g, mold 140CFU / g, yeast 130CFU / g, pathogenic bacteria (Salmonella, Staphylococcus aureus, Shigella, hemolytic strept...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com