Production method of konjac and colla corii asini jelly

A production method, the technology of donkey-hide gelatin fruit, is applied in the production field of konjac donkey-hide gelatin jelly, which can solve the problems of weak gelatin and difficult water absorption of jelly, achieve good water retention, improve immunity, and be applicable to a wide range of people

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

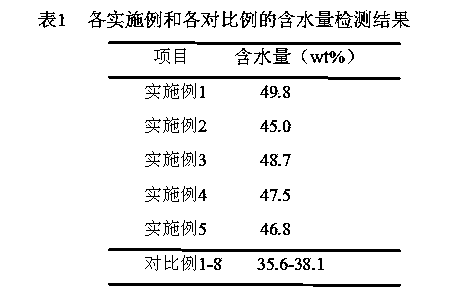

Examples

Embodiment 1

[0023] Present embodiment relates to a kind of production method of konjac donkey-hide gelatin jelly, comprising the following steps:

[0024] (1) Preparation of donkey-hide gelatin solution

[0025] 5 parts by weight of donkey-hide gelatin and 20 parts by weight of water are put into a boiling pot and boiled for 40 minutes, and after the donkey-hide gelatin is completely dissolved, filter to make a donkey-hide gelatin solution;

[0026] (2) Preparation of colloid

[0027] 3 parts by weight of konjac flour, 2 parts by weight of pectin, 1.5 parts by weight of carrageenan, 1.5 parts by weight of xanthan gum and 10 parts by weight of water are mixed and stirred to obtain a transparent and uniform glue solution after fully dissolving;

[0028] (3) Preparation of jelly

[0029] The donkey-hide gelatin solution of 2.5 parts by weight, the glue of 4.5 parts by weight, the fructose syrup of 2 parts by weight, the white granulated sugar of 1.5 parts by weight, the citric acid of...

Embodiment 2

[0031] Present embodiment relates to a kind of production method of konjac donkey-hide gelatin jelly, comprising the following steps:

[0032] (1) Preparation of donkey-hide gelatin solution

[0033] 4 parts by weight of donkey-hide gelatin and 20 parts by weight of water are put into a boiling pot and boiled for 30 minutes, after the donkey-hide gelatin is completely dissolved, filter to make a donkey-hide gelatin solution;

[0034] (2) Preparation of colloid

[0035] 2 parts by weight of konjac flour, 1.5 parts by weight of pectin, 2 parts by weight of carrageenan, 2 parts by weight of xanthan gum and 8 parts by weight of water are mixed and stirred to obtain a transparent and uniform glue solution after fully dissolving;

[0036] (3) Preparation of jelly

[0037] 3 parts by weight of donkey-hide gelatin solution, 5 parts by weight of glue, 1 part by weight of fructose syrup, 1.5 parts by weight of white sugar, 0.3 parts by weight of citric acid, 0.01 parts by weight ...

Embodiment 3

[0039] Present embodiment relates to a kind of production method of konjac donkey-hide gelatin jelly, comprising the following steps:

[0040] (1) Preparation of donkey-hide gelatin solution

[0041] 5 parts by weight of donkey-hide gelatin and 22 parts by weight of water are put into a boiling pot and boiled for 35 minutes, and after the donkey-hide gelatin is completely dissolved, filter to make a donkey-hide gelatin solution;

[0042] (2) Preparation of colloid

[0043] Mix and stir the konjac flour of 2.5 parts by weight, the pectin of 2 parts by weight, the carrageenan of 2.5 parts by weight, the xanthan gum of 1 part by weight and the water of 9 parts by weight, and obtain a transparent and uniform glue solution after fully dissolving;

[0044] (3) Preparation of jelly

[0045] 2 parts by weight of donkey-hide gelatin solution, 4 parts by weight of glue, 2 parts by weight of fructose syrup, 2 parts by weight of white sugar, 0.2 parts by weight of citric acid, 0.02...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com