Equipment and method for detaching waste television

A technology for TV sets and waste, which is applied in the field of comprehensive dismantling and resource reuse of waste electrical and electronic products, which can solve problems such as parts not being transported away in a timely manner, fluorescent powder not being absorbed in a centralized manner, and affecting the health of workers, so as to improve logistics efficiency , High work and logistics efficiency, clean and bright air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

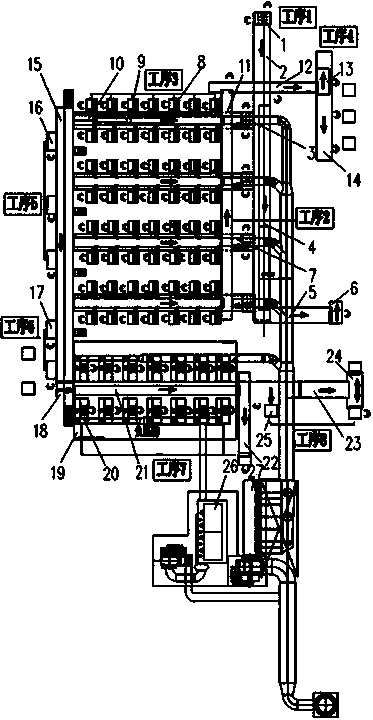

[0026] like figure 1 As shown, the waste TV dismantling equipment, its structure includes the cargo logistics conveying device, the dismantling operation platform, the TV picture tube screen cone cutting and separating machine and the supporting industrial vacuum treatment device, in which the cargo logistics conveying device and the dismantling operation platform part The back cover removal workbench 3 provided between them is connected; the TV picture tube screen cone cutting and separating machine 20 is evenly distributed on the two sides of the picture tube separation conveyor belt 18 in the lower layer of the negative pressure room and connected with it, and each TV picture tube screen cone is cut and separated. The front end of the working platform of the machine is designed to be connected with a dust removal cover, and at the same time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com