Selective laser melting rapid forming device

A technology of selective laser melting and laser forming, applied in the field of additive manufacturing, it can solve the problems of long laser idle time, reduced solidification speed of parts, and large accumulation of heat in powder bed, etc., so as to increase the scanning time interval between layers and reduce the utilization rate. , the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

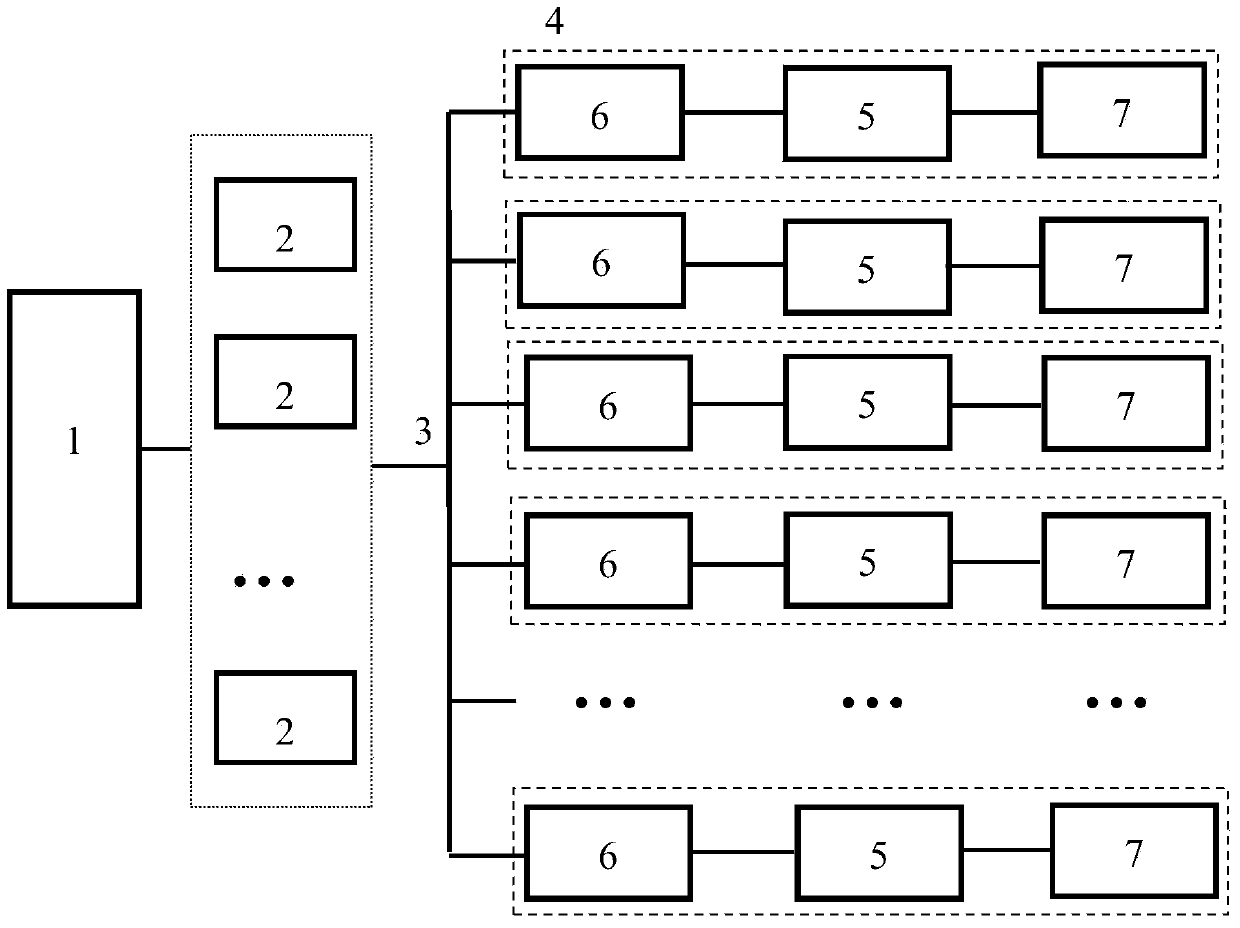

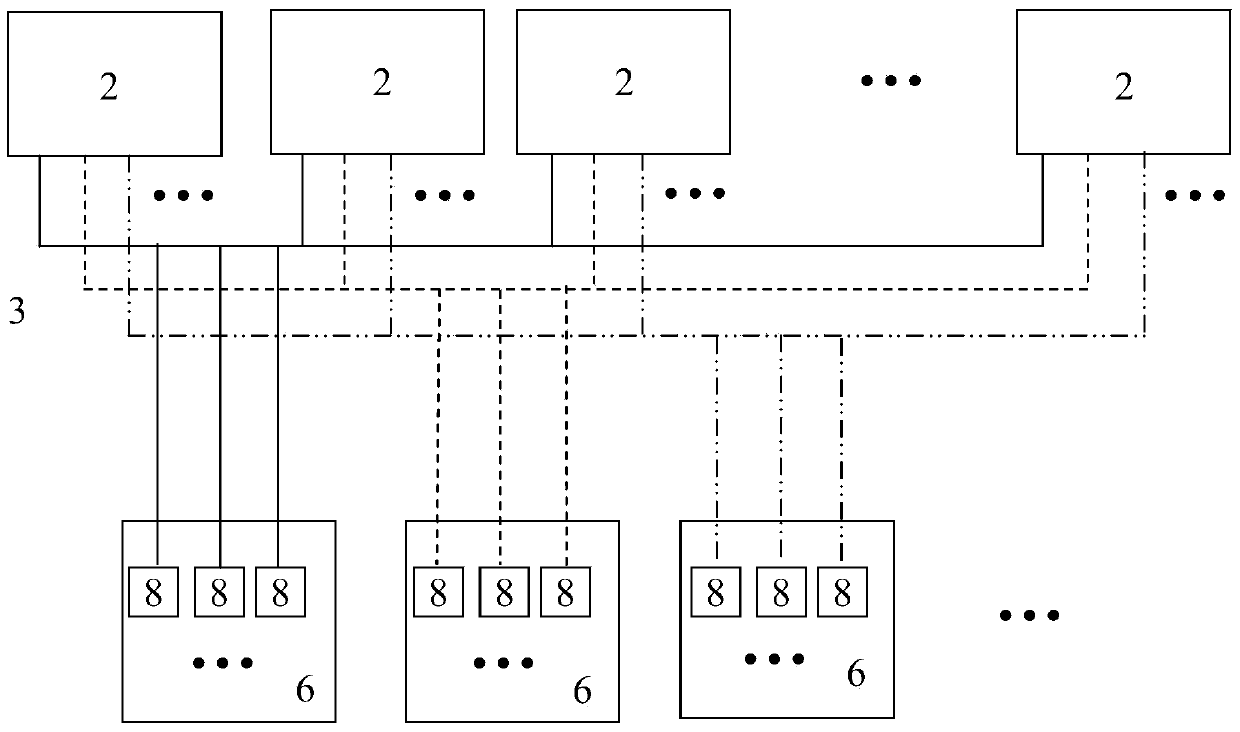

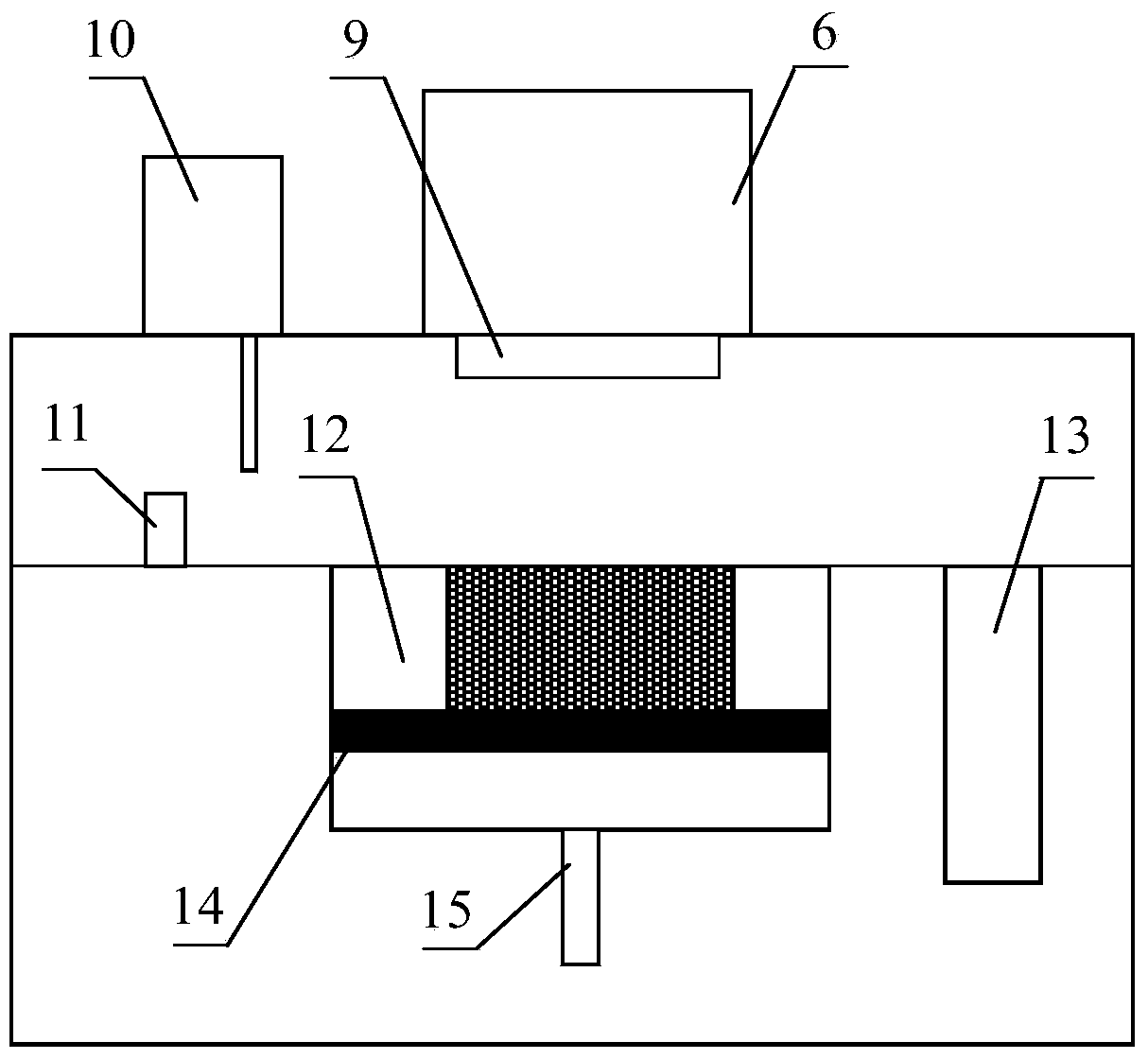

[0023] The existing SLM equipment is a single station, and its production process mainly includes processes such as powder feeding, powder spreading, laser scanning, and forming cylinder piston lowering. These processes are repeated in turn until the entire part is completed. During this period, the laser is only used during laser scanning and is idle for other times. But the present invention is different, the laser is always in the scanning state. For a certain station, the production process still repeats the steps of powder feeding, powder spreading, laser scanning, and molding cylinder piston down until the entire part is completed. However, there is a certain time difference between several stations and each production process. Taking four stations as an example, at a certain moment, station A is feeding powder, station B is spreading powder, station C is laser scanning, and station D is descending the forming cylinder piston. At the next moment, the A station spreads ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap