Hydrolytic acidification-muct combination high-concentration organic wastewater treatment device and method

A technology of organic wastewater treatment and hydrolysis and acidification, which is applied in the field of wastewater treatment equipment and high-concentration organic wastewater treatment equipment, can solve the problems of high cost of excess sludge treatment and disposal, slow denitrification rate, and large amount of excess sludge, etc. Water treatment effect, improvement of removal rate, and effect of reducing treatment and disposal costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

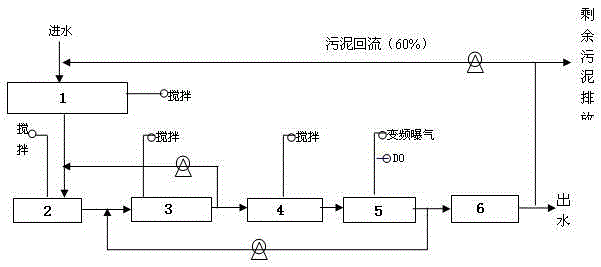

[0029] Embodiment: Carry out waste water treatment according to the following steps

[0030] (1) Inoculate the activated sludge from the aeration tank from the municipal sewage treatment plant into the hydrolytic acidification tank (1), inoculate the activated sludge from the sedimentation tank (6) into other MUCT pools, and domesticate the inoculated sludge , making the activated sludge MLSS value reach 5000mg·L -1 Above, the SV value is above 30; when the system is stable, the activated sludge MLSS value basically remains at 6200~6500mg·L -1 , SV value is 35~40;

[0031] (2) Flow the high-concentration organic wastewater from the pig farm into the hydrolytic acidification tank 1 with an effective volume of 120L, and start the agitator in the hydrolytic acidification tank, and make the wastewater undergo organic degradation reaction under the action of stirring. After the hydraulic retention time is 6 hours, The effluent mixture from the hydrolytic acidification tank 1 en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com