Method for purifying tagatose by using sequential simulated moving bed chromatography (SSMB)

A technology for simulating mobile chromatography and tagatose, which is applied in the field of sequential simulated mobile chromatography to purify tagatose, can solve the problem that tagatose cannot be efficiently purified, and achieves the advantages of increasing resin utilization rate, reducing concentration cost and reducing equipment investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

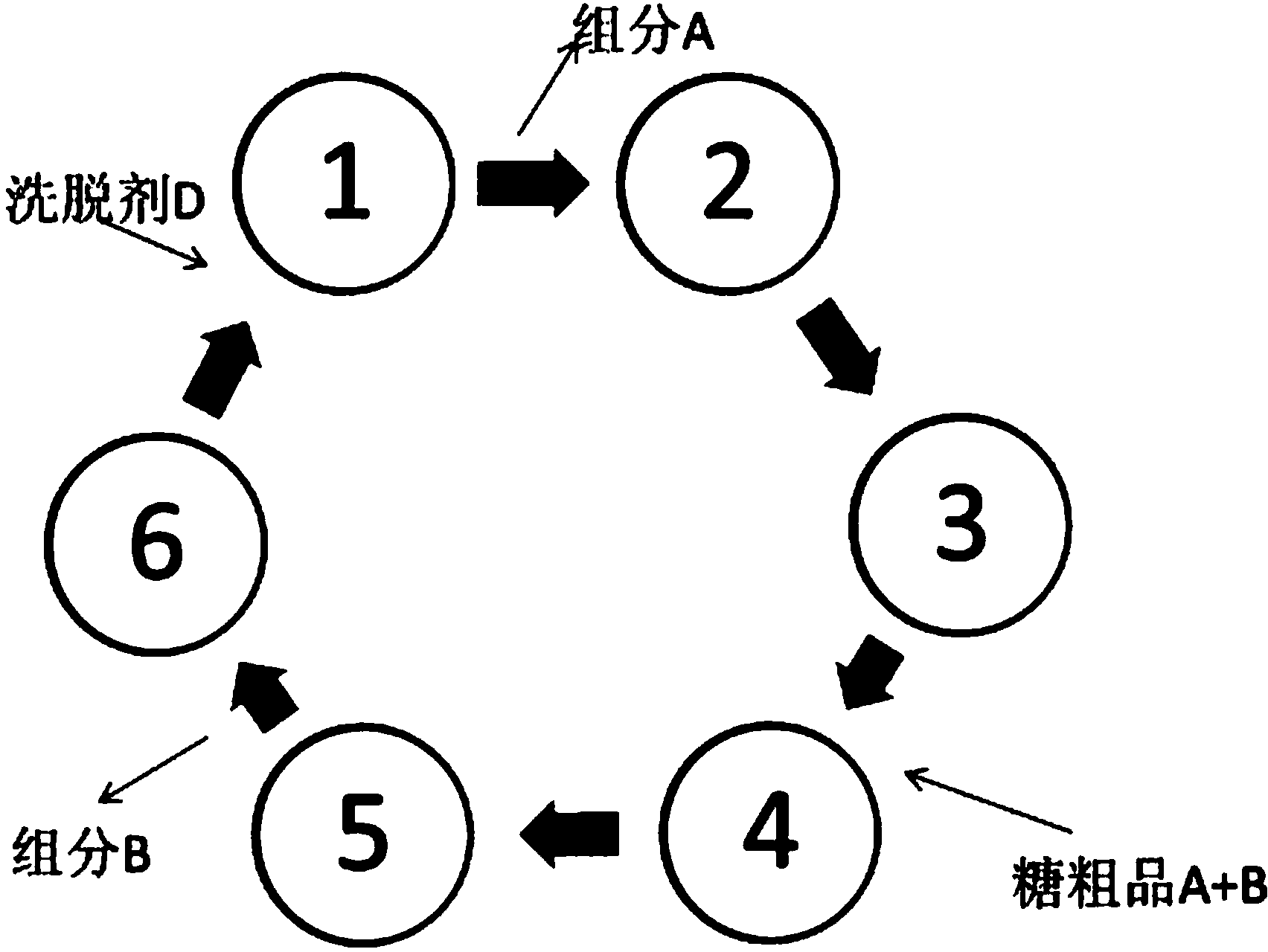

[0020] Such as figure 1 As shown, the sequential analog mobile chromatographic equipment used in the present invention consists of 6 chromatographic columns (inner diameter 35mm, length 1000mm), each chromatographic column is 1L, a total of 6L, and the inlet and outlet are controlled by solenoid valves. Achieved through the following steps:

[0021] A) Blending of feed syrup: blend the desalted and decolorized tagatose syrup to a concentration of 60%;

[0022] B) Filtration: filter the syrup solution obtained in step A) with a 50 micron filter to obtain a clear liquid without visible impurities;

[0023] C) Purification by sequential simulated mobile chromatography: the syrup obtained above is purified by sequential simulated mobile chromatography equipment, and the purification method is as follows:

[0024] a) Simultaneously feed materials, feed eluent, and discharge materials. Column 1 enters eluent D (deionized water), and component A (tagatose component) exits from the...

Embodiment 2

[0031] In the method for purifying tagatose by sequential simulated mobile chromatography of the present invention, the test adopts sequential simulated mobile chromatography equipment for purification. The sequential simulated mobile chromatography equipment used in the present invention is composed of 6 chromatographic columns (35 mm in inner diameter and 1000 mm in length). Each chromatographic column is 1L, a total of 6L, and the material in and out is controlled by a solenoid valve. It is achieved through the following steps:

[0032] A) operate according to step A) in embodiment 1;

[0033] B) operate according to step B) in embodiment 1;

[0034] C) Purification by sequential simulated mobile chromatography: the syrup obtained above is purified by sequential simulated mobile chromatography equipment, and the purification method is as follows:

[0035] a) Simultaneously feed materials, feed eluent, and discharge materials. Column 1 enters eluent D (deionized water), a...

Embodiment 3

[0042] In the method for purifying tagatose by sequential simulated mobile chromatography of the present invention, the test adopts sequential simulated mobile chromatography equipment for purification. The sequential simulated mobile chromatography equipment used in the present invention is composed of 6 chromatographic columns (35 mm in inner diameter and 1000 mm in length). Each chromatographic column is 1L, a total of 6L, and the material in and out is controlled by a solenoid valve. It is achieved through the following steps:

[0043] A) operate according to step A) in embodiment 1;

[0044] B) operate according to step B) in embodiment 1;

[0045] C) Purification by sequential simulated mobile chromatography: the syrup obtained above is purified by sequential simulated mobile chromatography equipment, and the purification steps are as follows:

[0046] a) Simultaneously feed materials, feed eluent, and discharge materials. Column 1 enters eluent D (deionized water), a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com