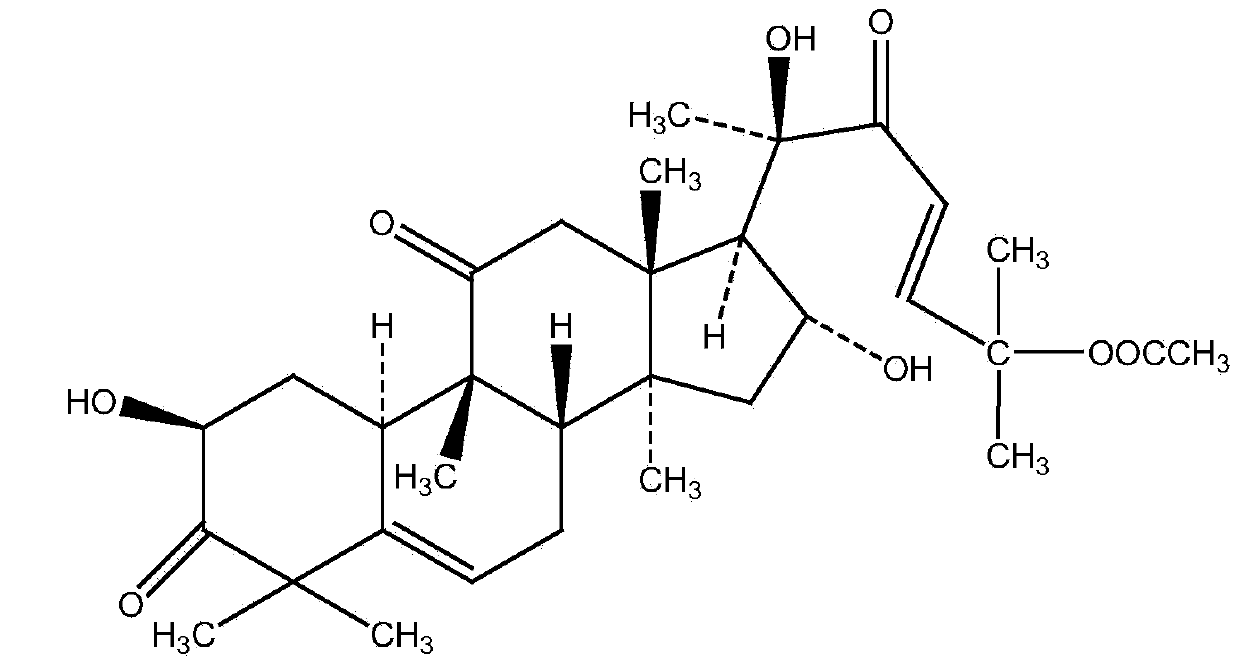

A method of preparing cucurbitacin B

A cucurbitacin and extraction technology, applied in the field of medicine, can solve the problems of high impurity content in the extract, complicated separation and purification process, unsuitable for large-scale production, etc., and achieve the effect of low toxicity, low dosage and low impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Take 2 kg of melon pedicles, crush them, pass through a 40-mesh sieve, and place them in the extraction kettle. Set the extraction pressure to 15 MPa, the extraction temperature to 40°C, the temperature of the analysis kettle I to be 45°C, the temperature of the analysis kettle II to be room temperature, and the pressure of the analysis kettles I and II to All are system pressure, after static extraction for 15min, then dynamic extraction for 25min (frequency 35KHz), sample I is obtained from the discharge port of analysis kettle I; Set the extraction pressure at 25MPa, the extraction temperature at 45°C, the temperature of the analysis kettle I at 50°C, the temperature of the analysis kettle II at 45°C, the pressures of the analysis kettle I and II are both the system pressure, and the dynamic extraction is 30min (frequency 35KHz) from the analysis kettle I. Feed mouth to get the extract. The solvent was recovered under reduced pressure and concentrated to a thick past...

Embodiment 2

[0023] Take 2 kg of melon pedicles, crush them, pass through a 40-mesh sieve, and place them in an extraction kettle. Set the extraction pressure to 25 MPa, the extraction temperature to 45°C, the temperature of the analysis kettle I to be 50°C, the temperature of the analysis kettle II to be room temperature, and the pressure of the analysis kettles I and II to Both are system pressure, add 3 times the ethanol of medicinal material amount (V / W) from carrier agent tank, after static extraction 25min, then dynamic extraction 40min (frequency 35KHz), get total cucurbitacin extract from the discharge port of analysis kettle I .

Embodiment 3

[0025] Take 2 kg of melon pedicles, crush them, pass through a 40-mesh sieve, and place them in an extraction kettle. Set the extraction pressure to 20 MPa, the extraction temperature to 40°C, the temperature of the analysis kettle I to be 45°C, the temperature of the analysis kettle II to be room temperature, and the pressure of the analysis kettles I and II to Both are system pressure, after static extraction for 10 minutes, then dynamic extraction for 30 minutes (frequency 35KHz), sample I is obtained from the discharge port of analysis kettle I; Esters, set the extraction pressure to 30MPa, the extraction temperature to 50°C, the temperature of the analysis kettle I to 55°C, the temperature of the analysis kettle II to 50°C, the pressure of the analysis kettle I and II to be the system pressure, and the dynamic extraction for 30min (frequency 35KHz) from the analysis kettle The I outlet gets the extract. The solvent was recovered under reduced pressure and concentrated to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com