Preparation method and application of polyurethane associative thickener

A technology of associative thickener and polyurethane, applied in the direction of coating, etc., can solve problems such as difficult dispersion, affecting workability, turbidity of thickener system, etc., and achieve good thickening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

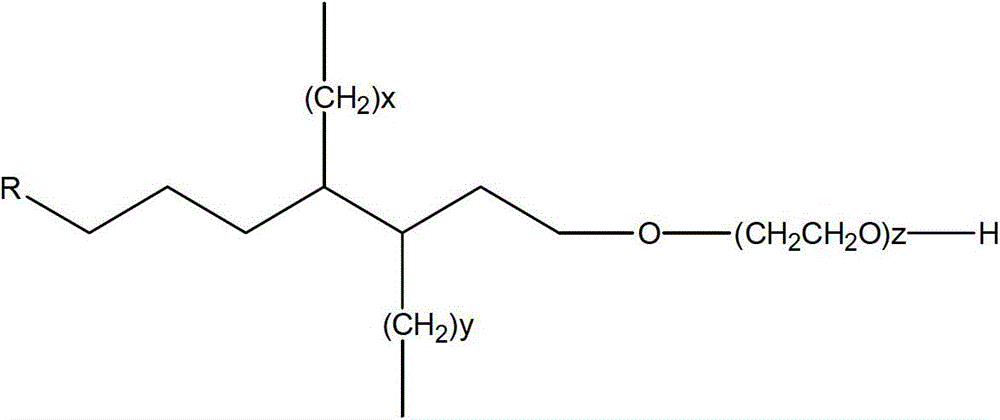

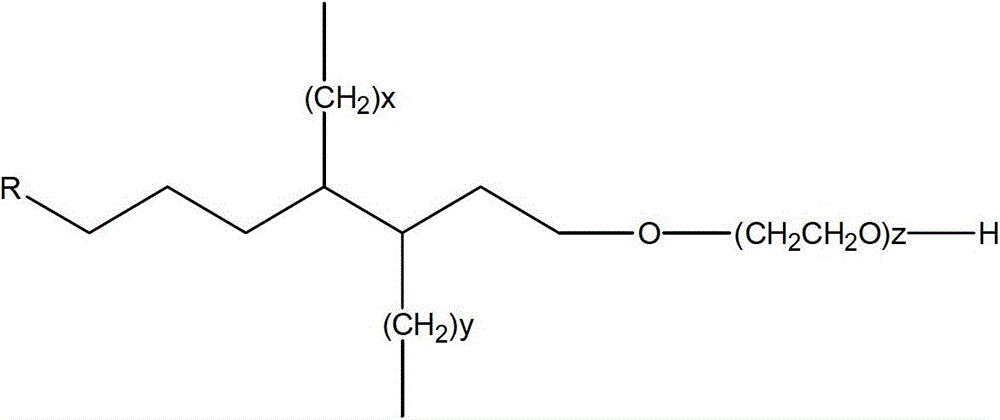

[0030] The embodiment of the present invention provides a kind of preparation method of polyurethane associative thickener, described method comprises:

[0031] Step 1: At 50~150°C, the dehydrated diol and diisocyanate are completely reacted under the action of a catalyst to obtain an intermediate;

[0032] In the examples provided by the present invention, the glycol dehydration is specifically carried out by the following method: put the glycol material into a reactor with a condenser tube and a thermometer, and dehydrate it at 80-120°C for 2-4 hours under vacuum. Hours until the moisture content of the material is less than 0.5%. Moisture content was determined using the Karl Fischer moisture method.

[0033] In order to ensure full contact and complete reaction between the diol and the diisocyanate, the reactor provided in the embodiment of the present invention is equipped with a stirring device. After the diol is dehydrated, a catalyst is added to the reactor, and the r...

Embodiment 1

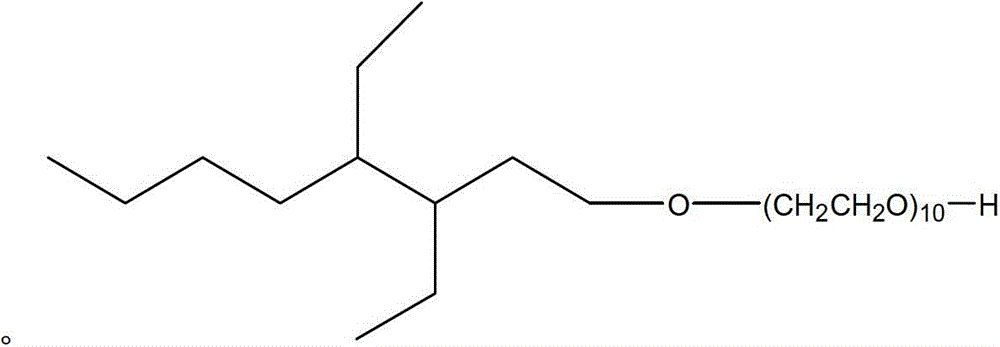

[0049] Weigh raw materials: Weigh 120g PEG6000, 6.66g IPDI, 0.063g dibutyltin maleate and 9.61g capping agent 1, wherein capping agent 1 is 3,4-diethyl-1-octanol polyoxyethylene ten Ether, its structural formula is as follows:

[0050]

[0051] Preparation of polyurethane associative thickener: put 120g of PEG6000 into a reactor equipped with a condenser, thermometer and stirring device, and dehydrate at 80°C for 4 hours under vacuum until the water content of the material is less than 0.1%. Add the catalyst dibutyltin maleate into the reactor, stir the dehydrated PEG6000 with a stirring device, and add IPDI dropwise to the dehydrated PEG6000 while stirring, after adding 6.66g of IPDI dropwise, react at 80°C for 12 hour, the mass percent content of NCO groups in the reaction system was detected to be 0.6%, and the midpoint reaction was ended. Add 9.61g of end-capping agent 1 into the reactor, stir and mix, and react at 80°C for 6 hours. After testing, the mass percentage o...

Embodiment 2

[0054] Weigh raw materials: Weigh 80g PEG8000, 3.490g TDI, 0.083g dibutyltin dilaurate and 9.61g capping agent 1.

[0055] Preparation of polyurethane associative thickener: put 80g of PEG8000 into a reactor equipped with a condenser, thermometer and stirring device, and dehydrate at 100°C for 2 hours under vacuum until the water content of the material is less than 0.5%. Add the catalyst dibutyltin dilaurate into the reactor, stir the dehydrated PEG8000 with a stirring device, and add TDI dropwise to the dehydrated PEG8000 while stirring, after adding 3.490g of TDI dropwise, react at 80°C for 12 hours, The mass percent content of NCO groups in the reaction system was detected to be 0.7%, and the midpoint reaction was terminated. Add 9.61g of end-capping agent 1 into the reactor, stir and mix, and react at 80°C for 6 hours. After testing, the mass percentage of NCO groups in the reaction system is 0.03%. After the reaction is completed, pour it out of the reactor while it is h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com