Improved supporting system construction method suitable for large overhung outer floating plate roof

A construction method and support system technology, which is applied in the direction of building structure support, building structure support, formwork/formwork/working frame, etc., can solve the problems of less openness and difficulty in supporting formwork for overhanging structures, and shorten the construction period and save turnover Materials, convenient and flexible to build and disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

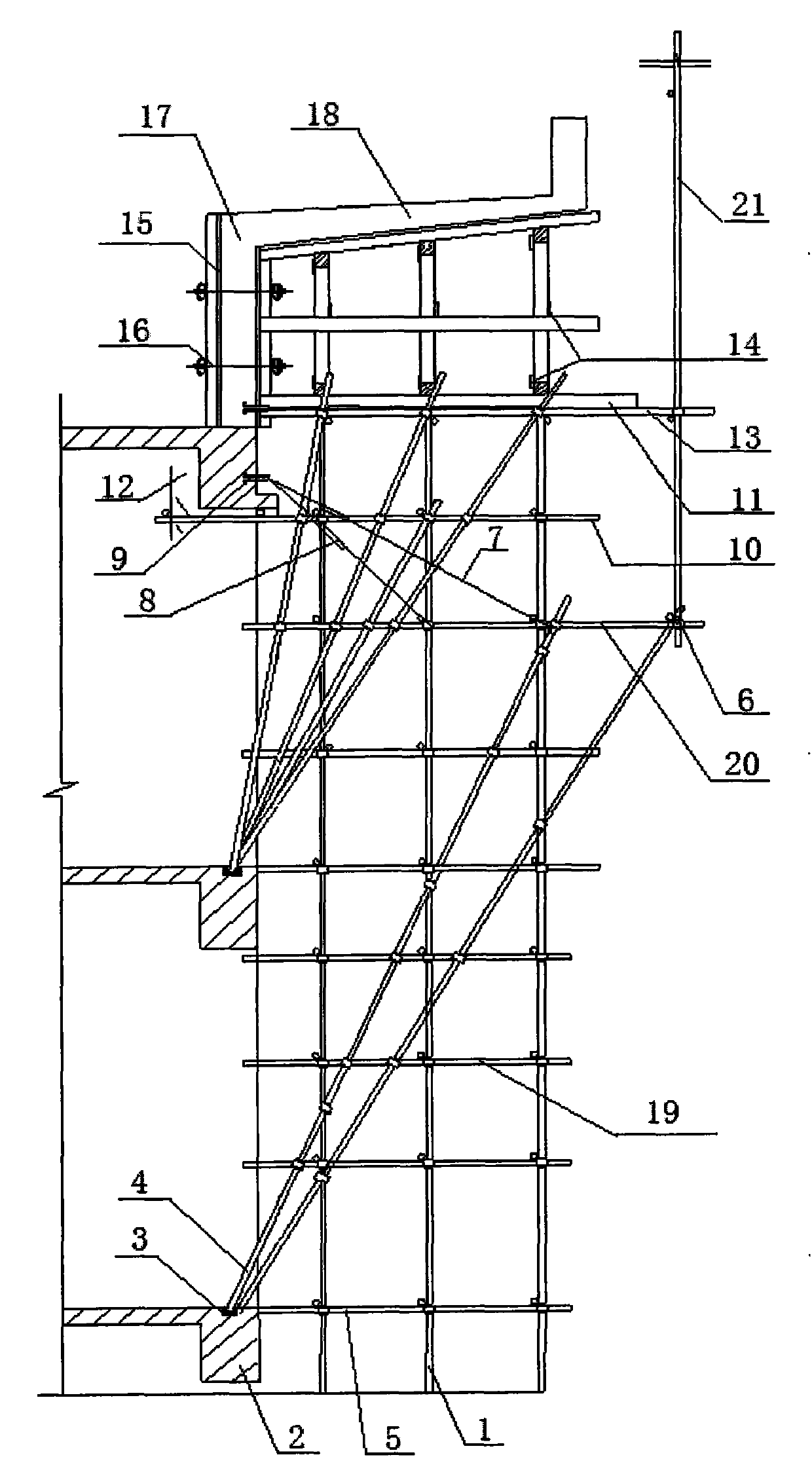

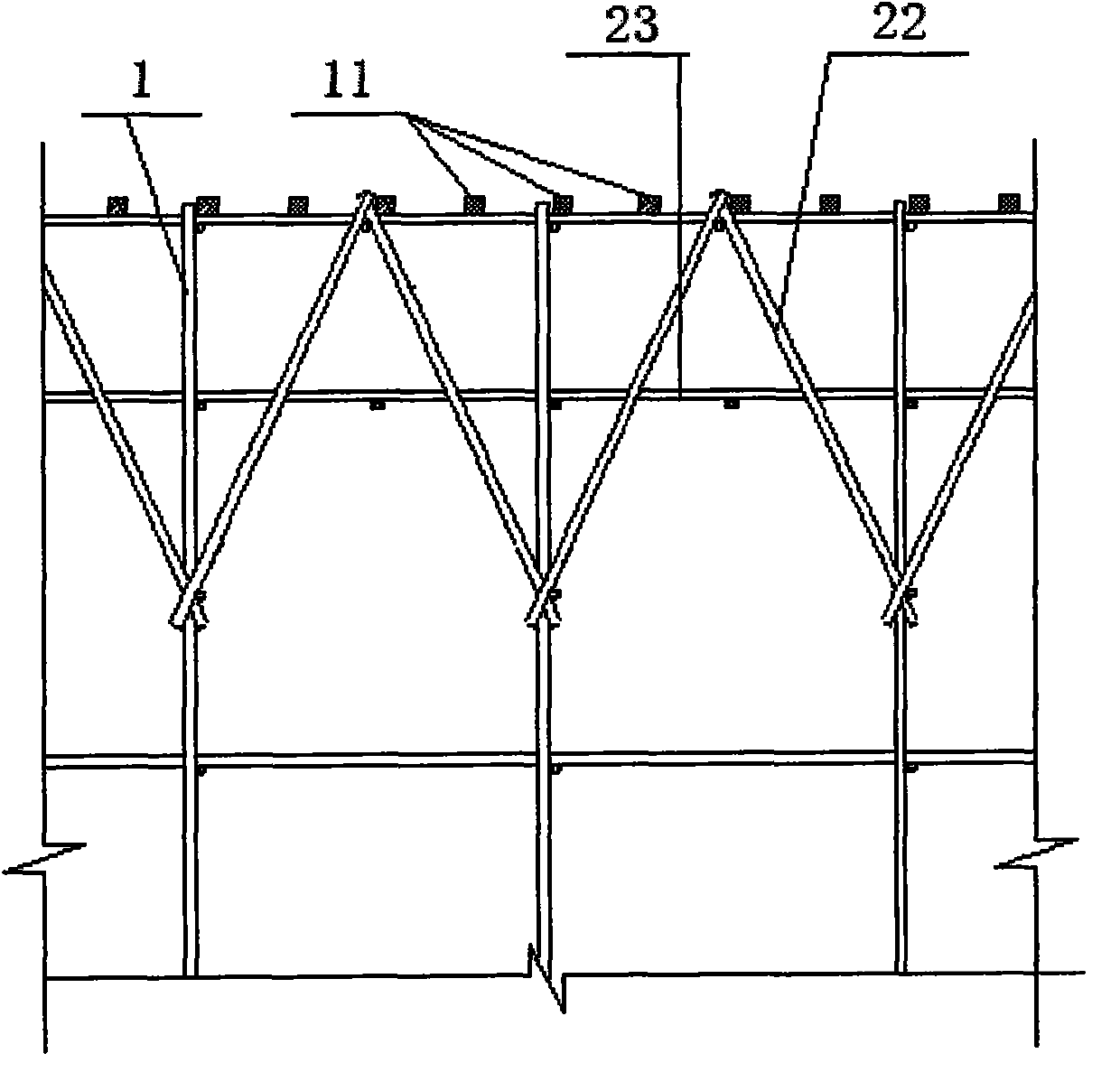

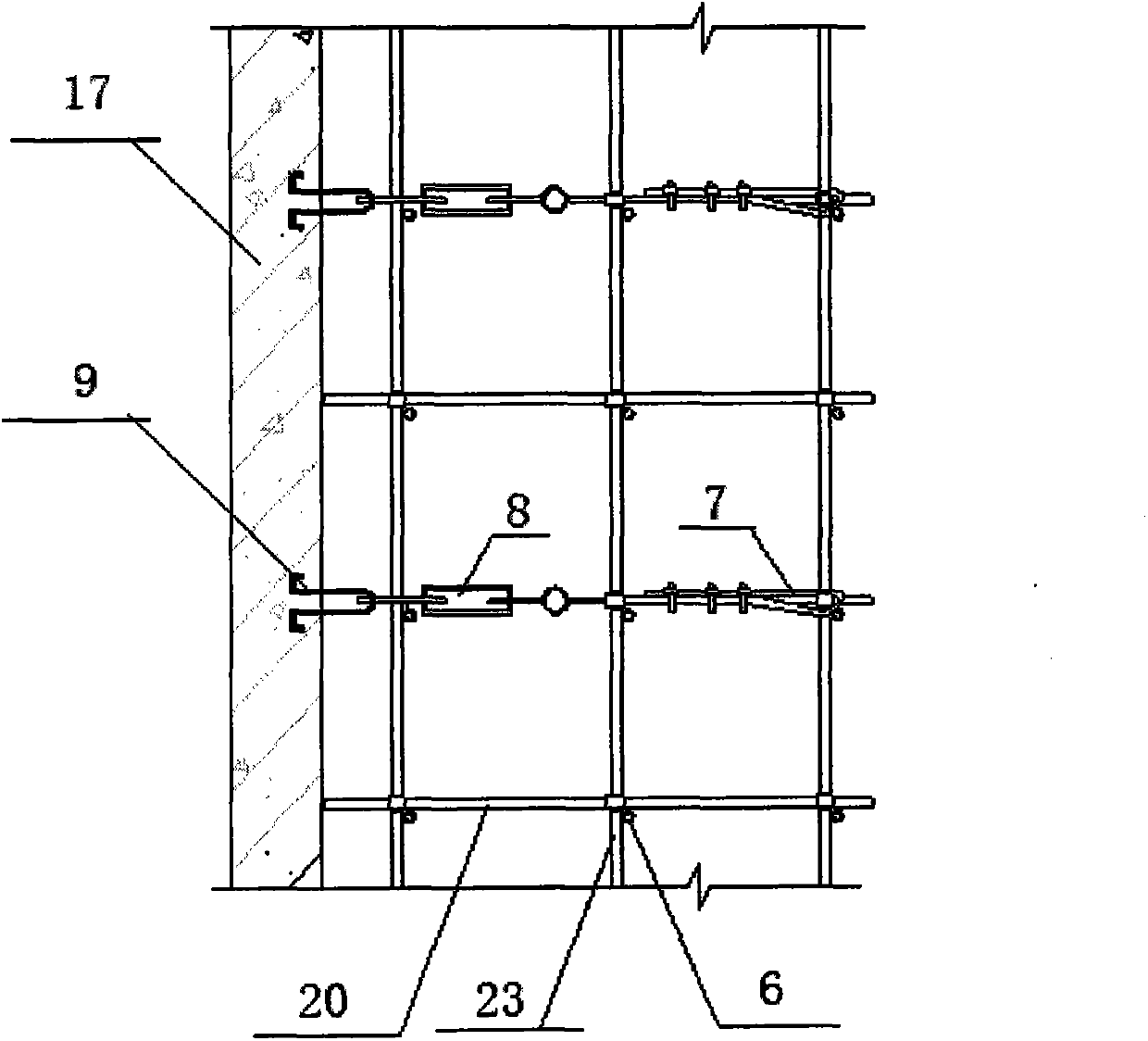

[0026] Embodiment 1: as attached Figure 5 As shown, the technological process includes: erecting double-row floor-standing steel pipe scaffolding → adding frame support oblique rods and horizontal suspension rods → performing frame reinforcement treatment → setting horizontal rod braces → strengthening fasteners → setting wall rods → carrying out Erection of support for the bottom formwork of the cantilevered parapet floating slab → stability check → acceptance of the bracket.

[0027] In the foregoing, the technical process is specifically:

[0028] ①Establish double-row floor-standing steel pipe scaffolding; after the backfill soil in the basement is compacted, set up double-row floor-standing steel pipe scaffolding directly under the top of the parapet; the horizontal spacing of the scaffolding is 0.8m, the longitudinal distance of the pole is 1.6m, and the step distance is 1.8m. The total height of the frame is about 36m;

[0029] ② Increase the frame supporting rods to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com