Magnetic resistance Z-axis gradient sensor chip

A gradient sensor and magnetoresistance technology, applied in the field of magnetic sensors, can solve the problems of poor stability, low magnetic field sensitivity of Hall effect sensors, and difficulty in controlling offset and sensitivity changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

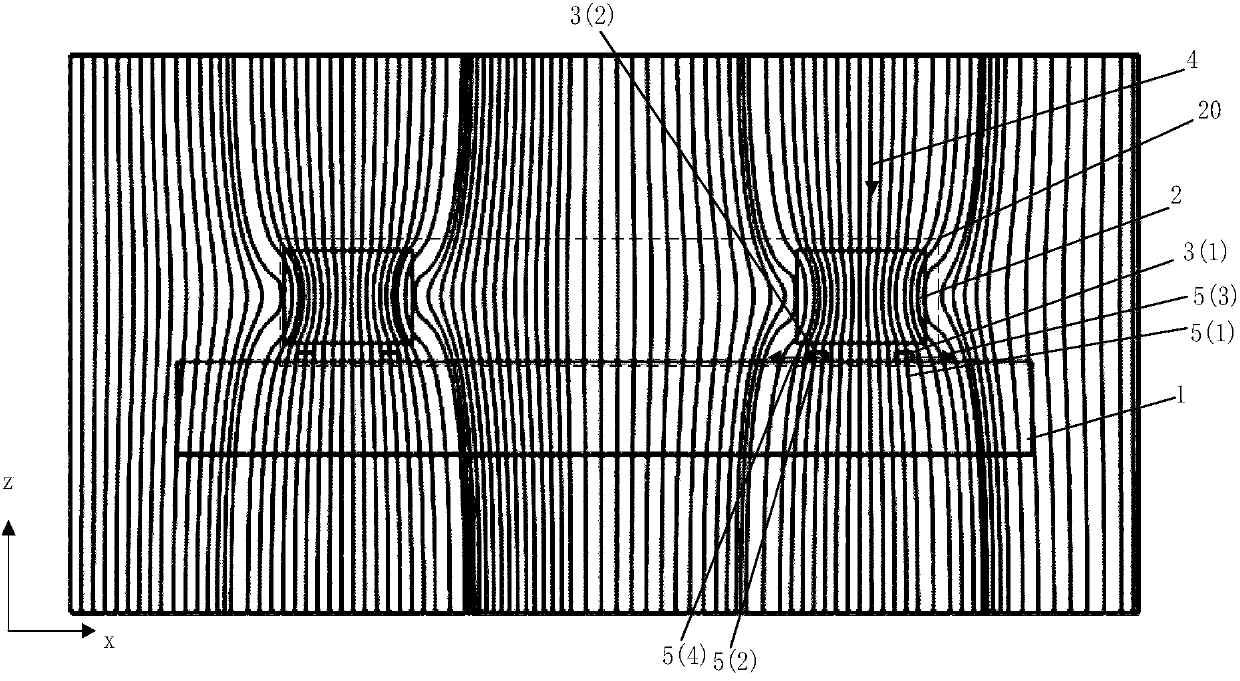

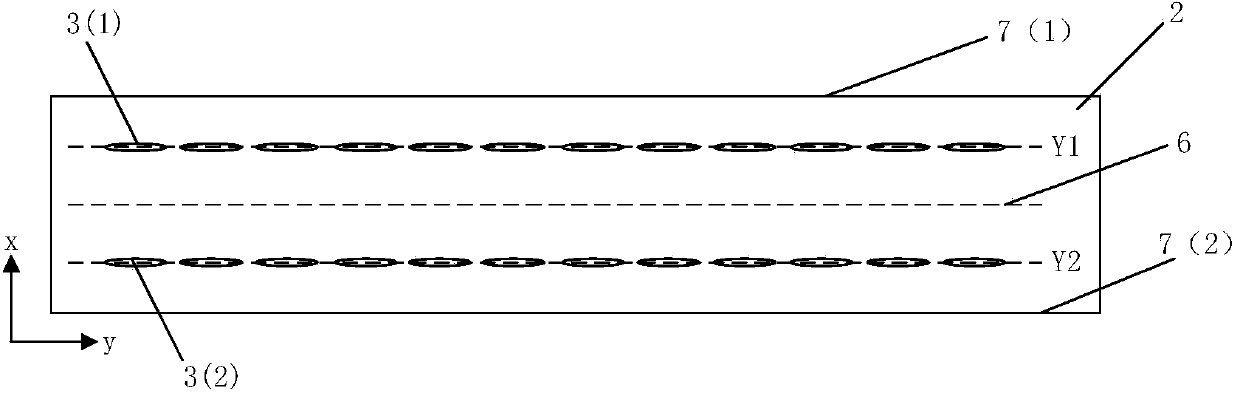

[0048] figure 1 It is a schematic diagram of a magnetoresistance Z-axis gradiometer chip, including a Si substrate 1, a magnetoresistance Z-axis sensor 20, and the magnetoresistance Z-axis sensor 20 is located on the Si substrate 1, and the magnetoresistance Z-axis sensor includes 2 or 2 groups containing multiple A magnetic flux guide 2 and a magnetoresistive unit 3 (including 3(1) or 3(2) in the figure), the magnetoresistive unit 3 is located above or below the flux guide 2, for simplicity, this figure only shows the magnetic The case where the resistance unit 3 is located below the flux guide 2 actually also includes the case where the magnetoresistive unit 3 is located above the flux guide 2 . The magnetic resistance unit 3 is electrically connected to form a half-bridge or full-bridge gradiometer. figure 1 The measurement principle of the Z-axis magnetic field is also given. After the Z-axis magnetic field 4 passes through the flux guide 2, since the flux guide 2 is a hi...

Embodiment 2

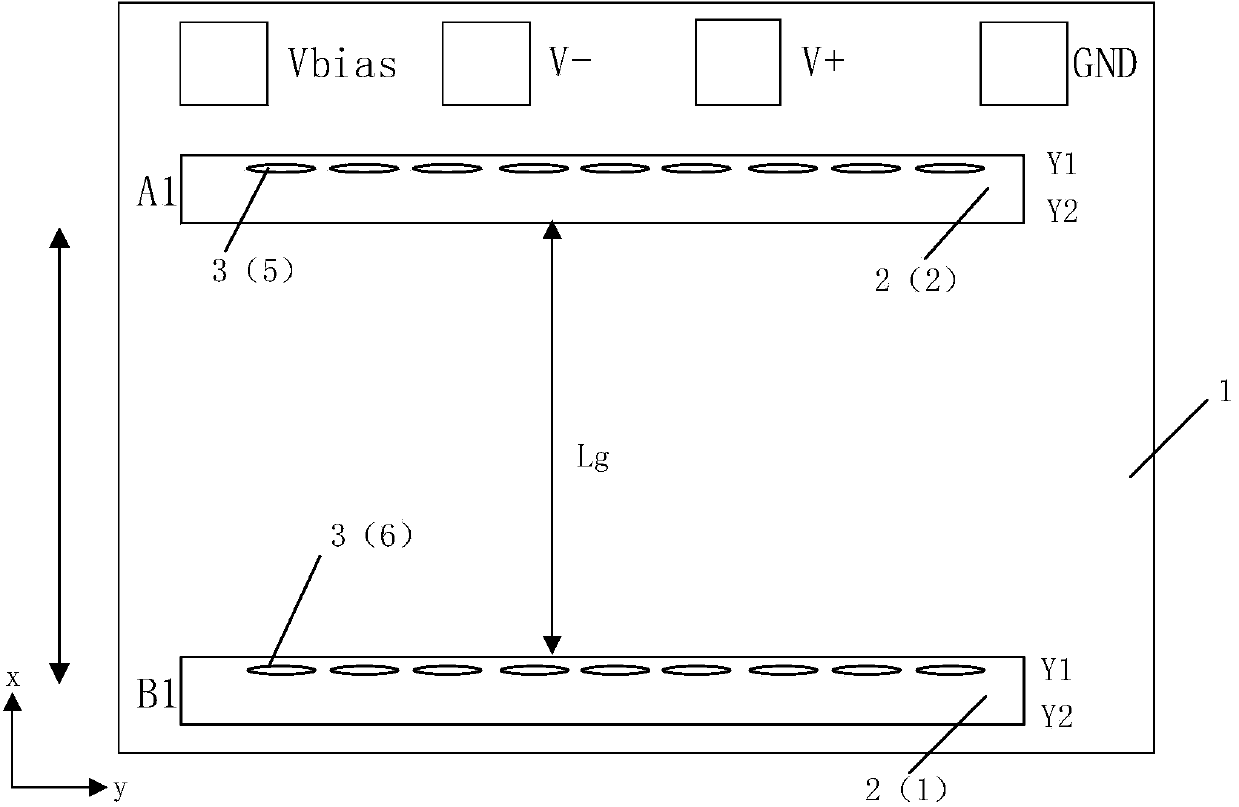

[0052] image 3 and Figure 4 It is another type of magnetoresistive Z-axis half-bridge gradient sensor chip and its electrical connection diagram, wherein the magnetoresistive units 3(5) and 3(6) on the two bridge arms of the half-bridge are respectively located in the flux guide In A1 and B1, and their occupied positions are the same, they are both located at Y1 or Y2, for the convenience of explanation, image 3 , 4 Only the case of being in the same Y1 position and having the same magnetic field sensitivity direction is given. At this time, the output signal of the half bridge can be calculated according to the following method:

[0053] After the Z-axis magnetic field HZ passes through the flux director, the X-axis direction magnetic field HX is obtained. The relationship between HZ and HX is:

[0054] HX1=HZ1*SXZ (1)

[0055] HX2=HZ2*SXZ (2)

[0056] Among them, SXZ is the magnetic field conversion parameter of the flux director, which is related to the geometric st...

Embodiment 3

[0066] Figure 5-7 It is a structural schematic diagram of a gradient sensor chip with a full-bridge structure and an electrical connection diagram of five corresponding magnetoresistance units. Figure 5 In , the corresponding positions Y1 and Y2 of the flux guides A1 and B1 are respectively occupied by the magnetoresistive units 3(7)-3(10) corresponding to the four bridge arms of the full bridge, where Figure 6 Among them, the two half-bridges of the full bridge correspond to the flux guides A1 and B1 respectively, the magnetoresistive units at the Y1 and Y2 positions of each flux guide have the same magnetic field sensitivity direction, and the two bridges connected to the electrodes The magnetoresistive units of the arms have the same magnetic field sensitivity direction. Figure 5 The output signal of the full bridge structure gradient sensor chip shown is shown in equations (5)-(7), and the measured Z-axis magnetic field gradient is shown in equation (8):

[0067] V-=...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com