Preparation method of nano-rod-shaped ZSM-48 molecular sieve

A nano-rod-shaped, molecular sieve technology, applied in the direction of crystalline aluminosilicate zeolite, can solve problems such as increasing cost and polluting the environment, and achieve the effect of high crystallinity and short diffusion path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

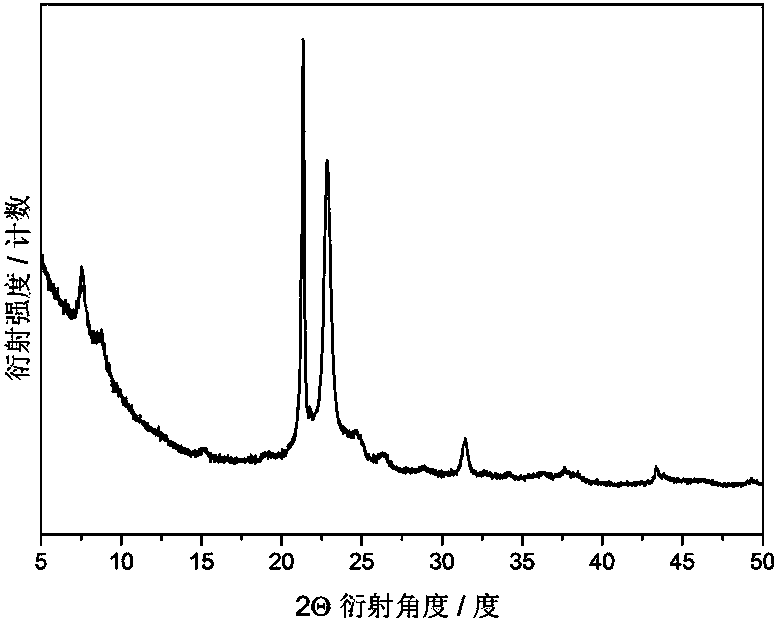

[0030] Prepare the initial gel in the following molar ratios: SiO 2 / Al 2 o 3 =100,OH - / SiO 2 =0.3, R / SiO 2 =0.2, H 2 O / SiO 2 Sodium aluminate, sodium hydroxide, and 1,4-(N-methylpiperidinyl)butane bromide were dissolved in deionized water at a ratio of =30, and then white carbon black was added under constant stirring. Afterwards, the above mixture was charged into a 100 ml crystallization kettle and reacted at 160° C. for 168 hours.

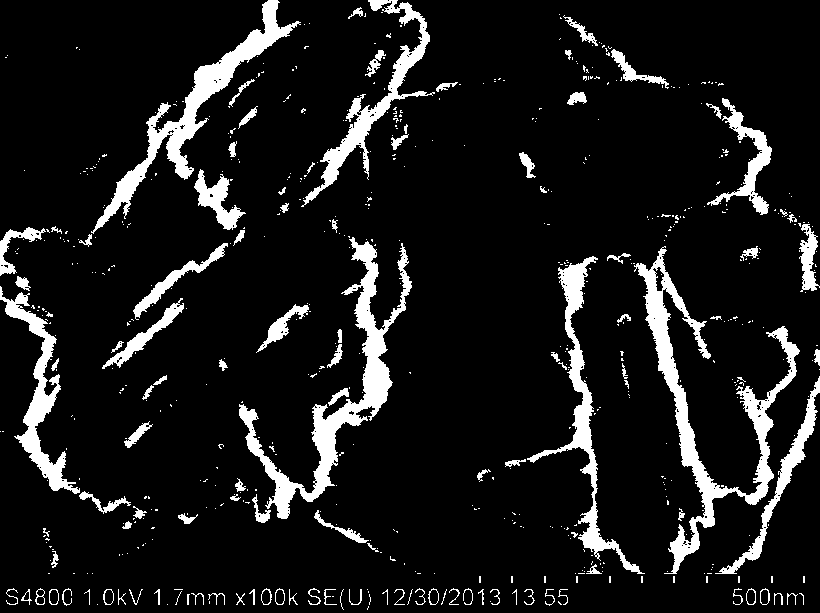

[0031] Put the cooled reaction solution in a water bath for 5 hours, after obvious layering, the yellow solid in the lower layer is ZSM-48 molecular sieve, which is separated, washed, dried, and calcined. After XRD analysis, it is confirmed to be nanorods Stacked ZSM-48 molecular sieve particles with a silicon-aluminum molar ratio of 29; characterized by SEM, the particle length is 1.5 μm, and the nanorod size is 30 nm. The yield of -48-1 was 90%.

Embodiment 2

[0033] Prepare the initial gel in the following molar ratios: SiO 2 / Al 2 o 3 =60,OH - / SiO 2 =0.3, R / SiO 2 =0.25, H 2 O / SiO 2 Sodium aluminate, sodium hydroxide, and 1,10-(N-methylpiperidinyl)decane bromide were dissolved in deionized water at a ratio of 40, and then white carbon black was added under constant stirring. Afterwards, the above mixture was charged into a 100 ml crystallization kettle and reacted at 175° C. for 192 hours.

[0034] Put the cooled reaction solution in a water bath for 10 hours, after obvious stratification, the off-white solid in the lower layer is ZSM-48 molecular sieve, which is separated, washed, dried, and calcined. After XRD analysis, it is confirmed to be nano Rod-shaped ZSM-48 molecular sieve with a molar ratio of silicon to aluminum of 23; characterized by SEM, the particle size is 700 nm, and the nanorod length is 50 nm. Numbering is ZSM-48-2, and the productive rate of ZSM-48-2 is 82% in terms of the silica weight of feeding.

Embodiment 3

[0036] Prepare the initial gel in the following molar ratios: SiO 2 / Al 2 o 3 =200,OH - / SiO 2 =0.5, R / SiO 2 =0.16, H 2 O / SiO 2 Dissolve sodium aluminate, sodium hydroxide, and the above organic templates in deionized water at a ratio of =15, add silicic acid without stirring, and then put the above mixture into a 100 ml crystallization kettle at 160°C Reaction for 120 hours.

[0037] Put the cooled reaction solution in a water bath for 10 hours, and after obvious stratification, the white solid in the lower layer is ZSM-48 molecular sieve, which is separated, washed, dried, and roasted and then analyzed by XRD to confirm that it is a nanorod The rice grain-shaped ZSM-48 molecular sieve formed by stacking has a silicon-aluminum molar ratio of 80; after SEM characterization, the particle size is 600 nm, and the length of the nano-sized grains is 50 nm. Numbering is ZSM-48-3, and the productive rate of ZSM-48-3 is 94% in terms of the silica weight of feeding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com