System and technique for simultaneously purifying methane and carbon dioxide from marsh gas

A technology of carbon dioxide and biogas, applied in the direction of membrane purification/separation, hydrocarbon purification/separation, inorganic chemistry, etc., can solve the problems of aggravating the greenhouse effect and affecting the environment, and achieve the effect of simple process, high degree of automation and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

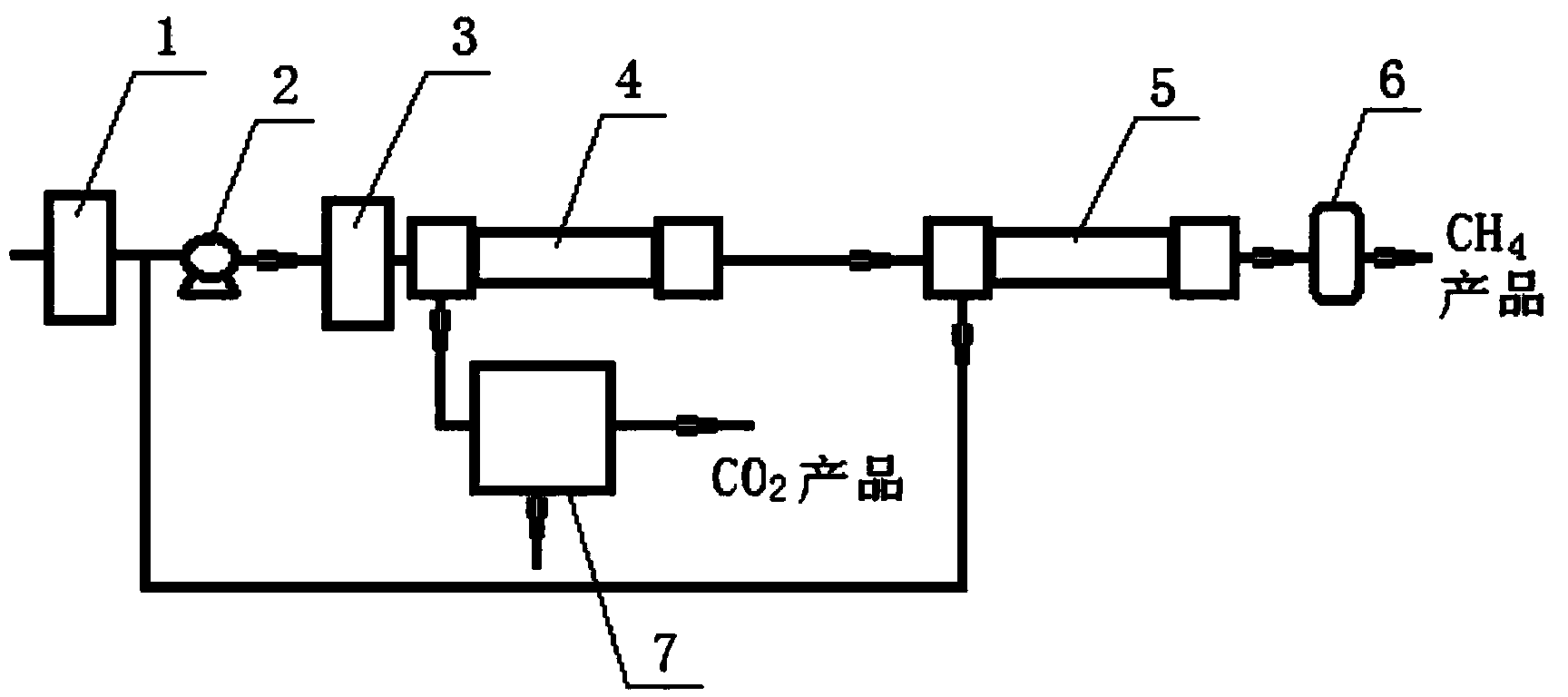

[0052] Embodiment 1: Two-stage membrane separation process

[0053] A process for simultaneously purifying methane and carbon dioxide from biogas, comprising the following steps:

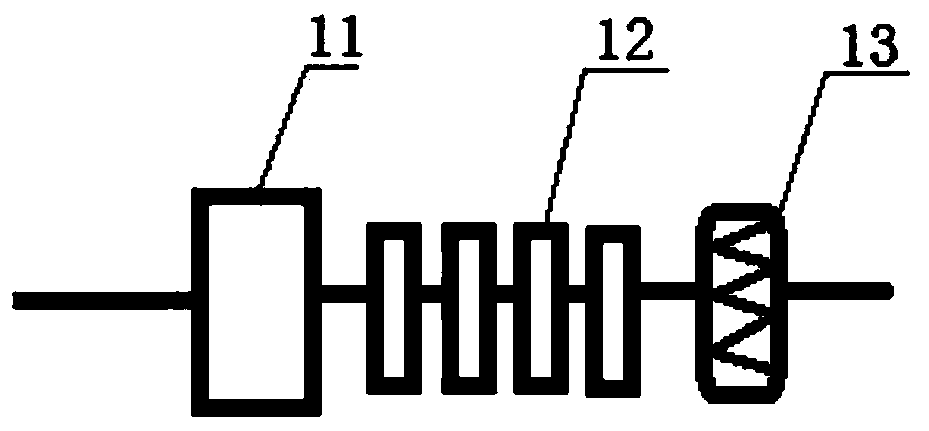

[0054] (1) After biogas raw material is desulfurized and dehydrated by biogas desulfurization dehydrator 1, it is compressed and pressurized to 1.35MPa by compressor I2, and then enters pretreatment device I, and passes through cold dryer I, filter group I (including 4 connected in series) Class filter) treatment, the filtration accuracy reaches 0.01μm / Nm3 for dust, 0.01mg / Nm3 for residual oil, less than 100ppm for ammonia or amine, H 2 S is less than 15ppm, then passes through the heater I, the temperature reaches 35°C, and enters the first-stage hollow fiber membrane 4 for CO 2 and CH 4 rough separation;

[0055] (2) Obtain CO at the permeate gas outlet of the first-stage hollow fiber membrane 4 2 Crude product (94% CO 2 , 4v% CH 4 , others are O 2 , N 2 etc.), the CH obtained from the non...

Embodiment 2

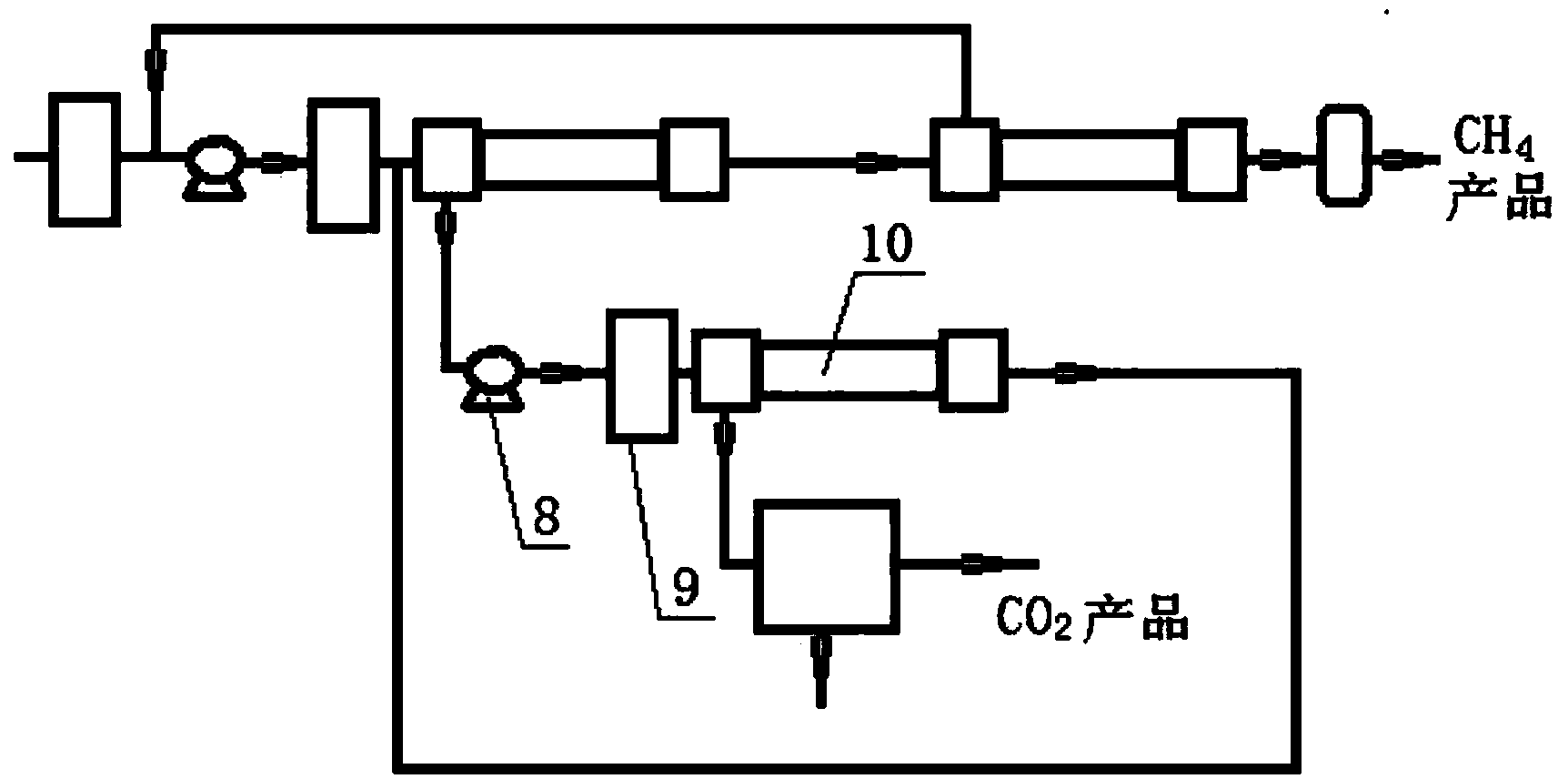

[0058] Embodiment 2: Three-stage membrane separation process

[0059] (1) Biogas raw materials are desulfurized and dehydrated by biogas desulfurization dehydrator 1, compressed and pressurized by compressor I2 to 1.0MPa, then enter pretreatment device I3, pass through cold dryer I11, filter group I12 (including series connected 4-stage filter) and heater Ⅰ13 pretreatment, the filtration accuracy reaches 0.01μm / Nm3 for dust, 0.01mg / Nm3 for residual oil, less than 100ppm for ammonia or amine, H 2 S is less than 15ppm, the temperature reaches 40°C, and then enters the first-stage hollow fiber membrane 4 for CO 2 and CH 4 rough separation;

[0060] (2) Obtain CO at the permeate gas outlet of the first-stage hollow fiber membrane 4 2 Crude product (90v% CO 2 , 8v% CH4, others are O 2 , N 2 etc.), through the compressor II8, compressed to 1.1MPa, enter the pretreatment device II9, after the pretreatment of the cold dryer II, the filter group II (including the 4-stage filter c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com