Polyvinyl chloride cleaning closed loop preparation system and method

A polyvinyl chloride, production system technology, applied in the field of resource comprehensive utilization production system of polyvinyl chloride integration project, to achieve the effect of reducing dust content in exhaust gas, reducing raw material and power consumption, and benefiting environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

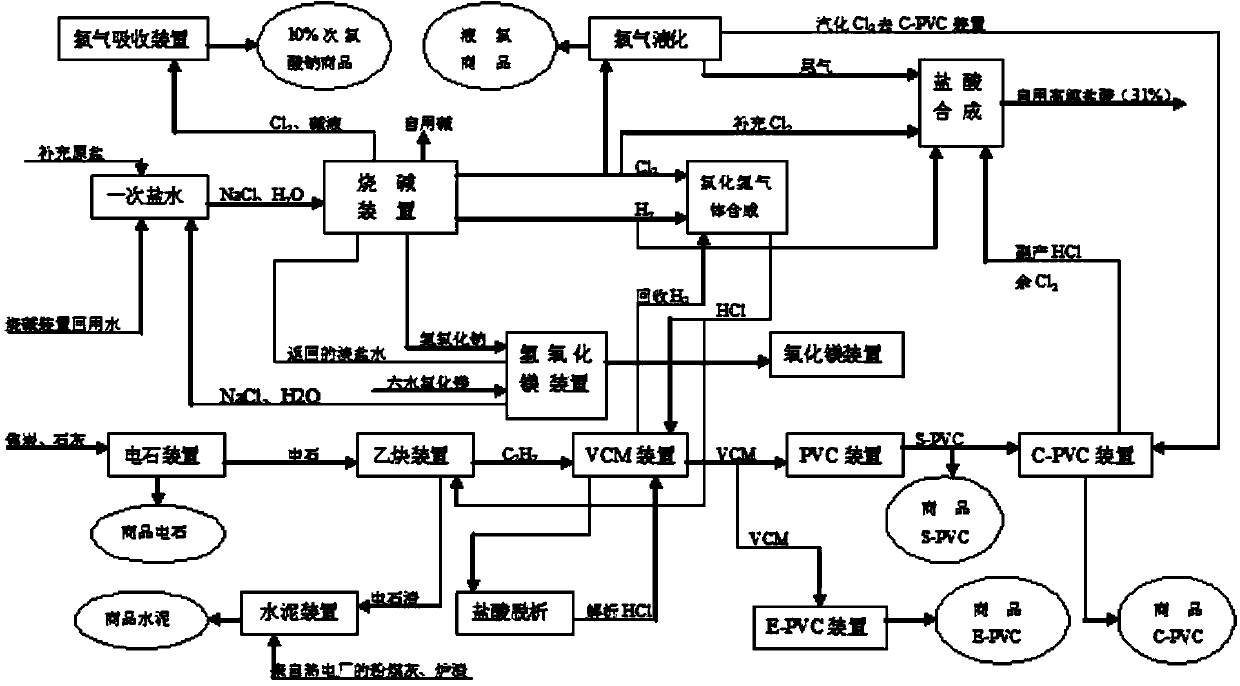

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] Such as figure 1 Shown is a schematic diagram of the production process of the clean closed-loop production system for polyvinyl chloride of the present invention.

[0034] A clean closed-loop production system for polyvinyl chloride, comprising: a chlorine absorption device, a caustic soda device, a magnesium hydroxide device, a magnesium oxide device; a calcium carbide device, an acetylene device, a vinyl chloride (VCM) device, a PVC device, a chlorinated polyvinyl chloride ( C-PVC) device, E-PVC device, cement device, it is characterized in that, described chlorine absorption device, caustic soda device, magnesium hydroxide device, magnesium oxide device are sequentially connected, and the product of previous device is the raw material o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com