A continuous annealing device for thermochromic coating materials on sheet substrates

A thermochromic coating and annealing device technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve problems such as unsuitable thermochromic smart glass annealing treatment, unfavorable safety performance of glass heating, etc., to shorten production time and reduce tempering stress The effect of low loss and low overall temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

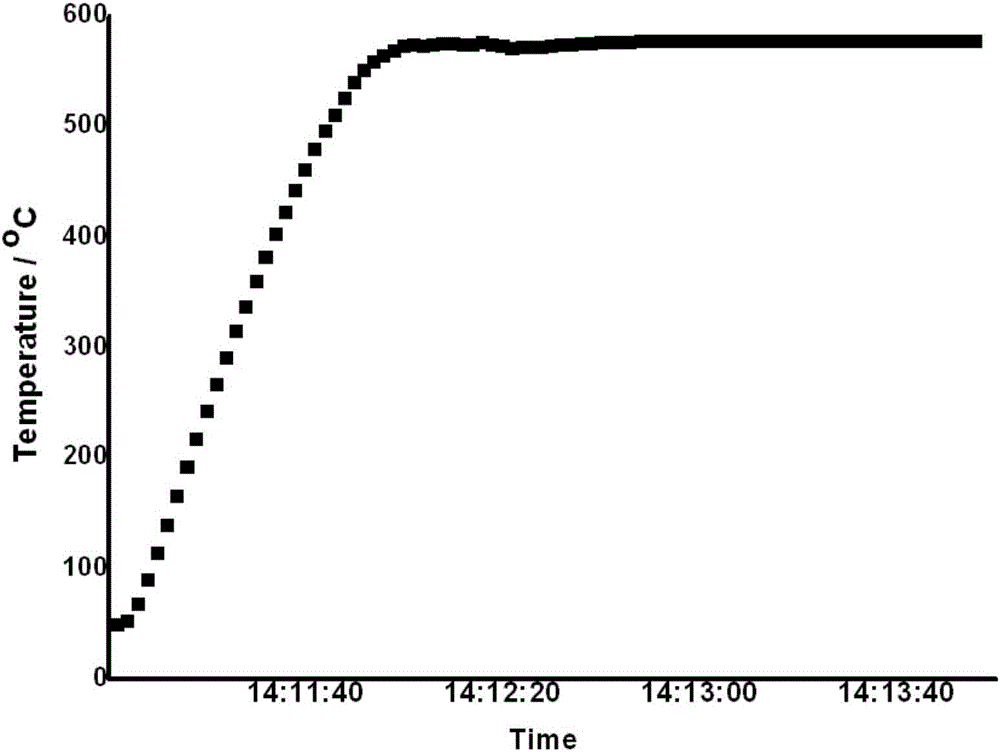

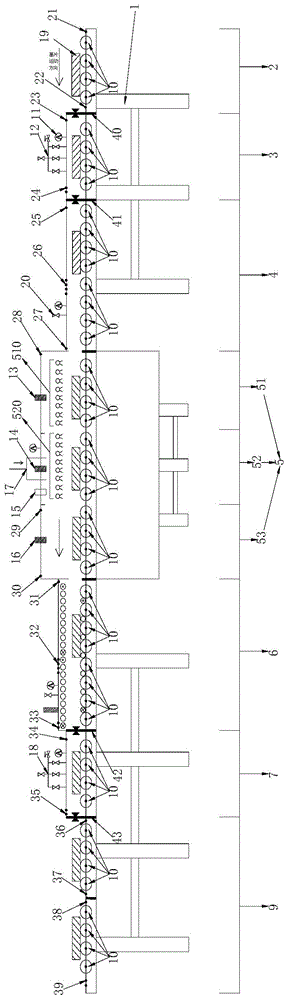

[0053] Taking tempered glass as the substrate coated with thermochromatic coating materials as an example, such as Figure 1-6 The shown continuous annealing device for thermochromic coating materials on sheet substrates includes a working platform 1 . The working platform 1 is provided with a feeding area 2 and a feeding area 9 . Several functional units are arranged between the loading area 2 and the unloading area 9, which are the first vacuum chamber 3, the heat treatment chamber and the second vacuum chamber 7 in sequence. The chambers are separated by dynamic airtight doors. The heat treatment chamber can also be divided into a vacuum zone 4, a heat treatment zone 5 and a cooling zone 6 according to functions. The heat treatment area 5 can also be divided into a preheating section 51 , an annealing section 52 and an isolation section 53 according to functions.

[0054] like figure 1 As shown, the working platform 1 is provided with a transmission mechanism composed o...

Embodiment 2

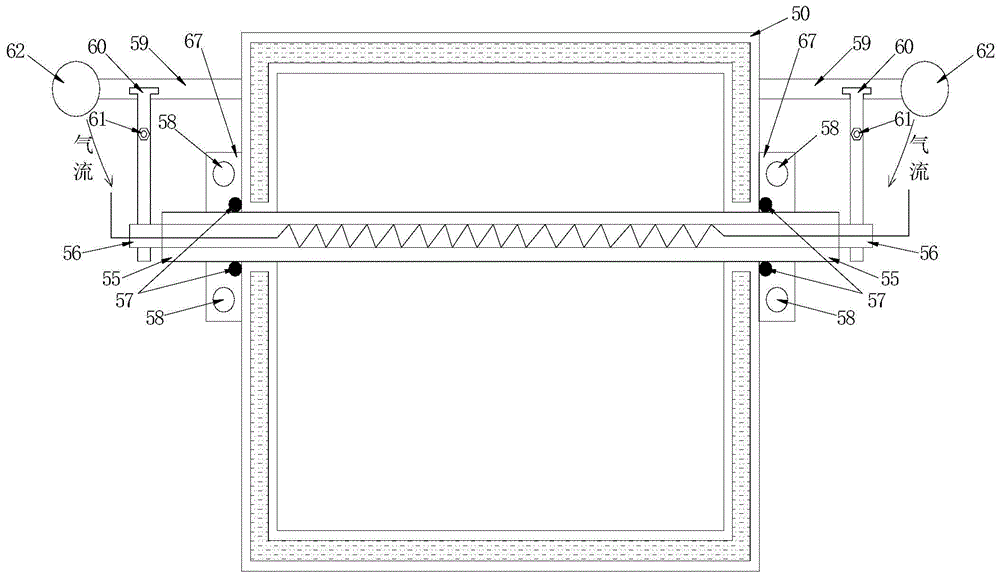

[0072] like Figure 10 and 11 As shown, the difference between Embodiment 2 and Embodiment 1 is that an air grid quenching zone 8 is also provided between the second vacuum chamber 7 and the feeding zone 9 . like Figure 8 As shown, a set of independently operable transfer rollers 10 is also provided in the air grid quenching zone 8 . A plurality of arranged air ducts are arranged above and below the transmission mechanism, which are respectively a first air duct 81 and a second air duct 82 . Several air nozzles 83 are opened on each air pipe. After the substrate enters the air grid quenching zone 8 from the second vacuum chamber 7, the blower blower connected with the first air pipe 81 and the second air pipe 82 blows the air along the air flow. Blow toward the substrate in the airflow direction shown in the figure to achieve the purpose of rapid cooling.

[0073] The substrate containing the thermochromic coating material on the surface enters the rapid cooling zone 8 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com