A New Air Separator for Ammonia Refrigeration

An air separator and ammonia refrigeration technology, applied in the field of separators, can solve the problems of excessive power consumption of compressors, low total heat transfer coefficient, large mass transfer resistance, etc., and achieve easy operation and maintenance, broad market prospects, and improved work efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

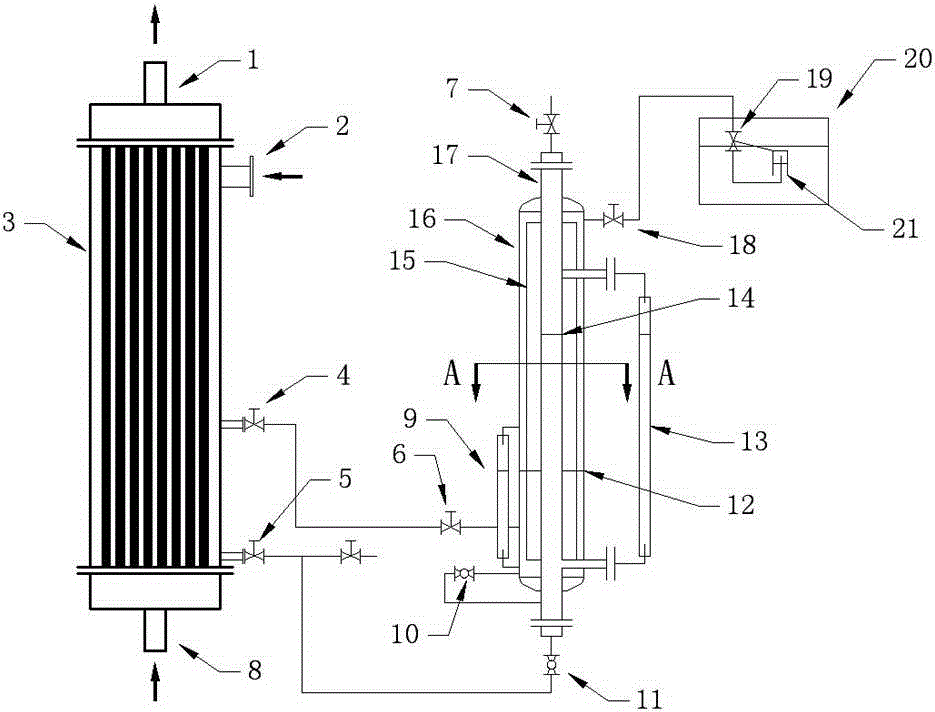

[0024] Now in conjunction with accompanying drawing, the present invention is described in further detail.

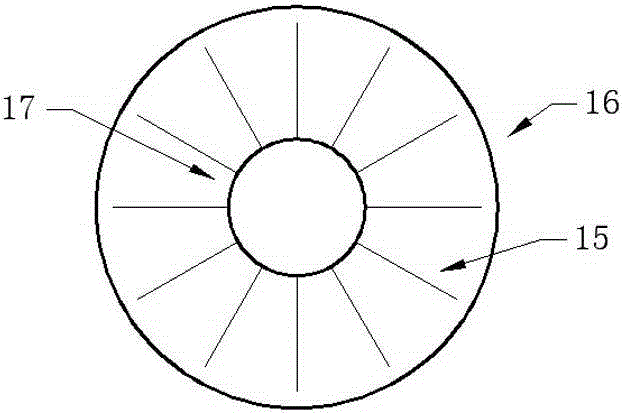

[0025] Such as figure 1 and figure 2 The new air separator for ammonia refrigeration shown includes a tube heat exchanger 3, the lower tube side of the tube heat exchanger is connected to the cooling water inlet pipe 8, the upper tube side is connected to the cooling water outlet pipe 1, and the shell side of the tube heat exchanger is The top is provided with an air inlet 2, the bottom of the shell side is connected to the bottom of the inner cylinder 17 through the pipeline, the valve 5 and the expansion valve 11, and the top of the inner cylinder 17 is connected to the low pressure end of the ammonia refrigeration system through the pipeline and the valve 7; There is an outer cylinder 16, the outer wall of the inner cylinder 17 and the inner wall of the outer cylinder 16 form a sealed cavity, and the outer wall of the inner cylinder is welded with a finned plate 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com