Calcium carbide furnace based calcium carbide sensible heat power generation system and implementation method thereof

A technology for a power generation system and a realization method, which is applied to steam generation methods using heat carriers, furnaces, waste heat treatment, etc., which can solve problems such as waste of heat energy and ineffective use of sensible heat of calcium carbide products, and reduce energy consumption and labor costs. The link of operation, the effect of low crushing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

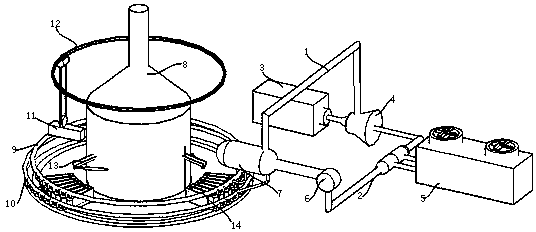

[0025] Such as figure 1 As shown, this embodiment provides a carbide sensible heat power generation system based on calcium carbide furnace. The power generation system is combined with the production process of calcium carbide, replacing the traditional natural cooling method of calcium carbide, and effectively recovering the sensible heat of calcium carbide for power generation. On the one hand , effectively recovered the sensible heat of calcium carbide, and the electricity generated accounted for about 6% to 8% of the input electricity of the calcium carbide furnace. On the other hand, the ambient temperature was reduced, and the manual operation was greatly reduced, effectively reducing the worker Hazards at work.

[0026] In order to make those skilled in the art have a clearer understanding and understanding of the present invention, it is described in detail below:

[0027] The calcium carbide sensible heat power generation system mainly includes an annular heat excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com