Positive photosensitive resin composition and method for forming patterns by using the same

A technology of photosensitive resin and composition, which is applied in optics, optomechanical equipment, nonlinear optics, etc. It can solve the problems of reduced process yield, poor cross-sectional shape of pattern, and inability to form patterns, etc., and achieve the effect of good cross-sectional shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

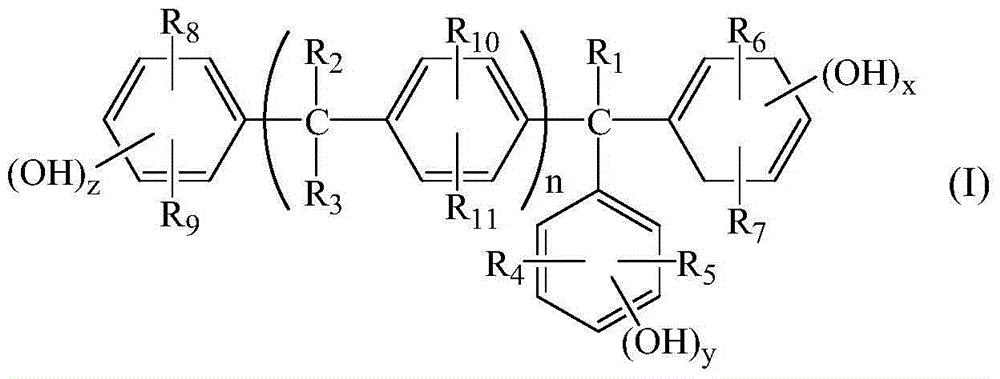

Synthetic example A-1-1

[0094] A four-necked conical flask with a volume of 1000 ml is equipped with a nitrogen inlet, a stirrer, a heater, a condenser and a thermometer. After the nitrogen is introduced, 0.70 mol of m-cresol, 0.30 mol of p-cresol, and 3,4-dihydroxy are added. 0.5 moles of benzaldehyde and 0.020 moles of oxalic acid. Stir slowly to raise the temperature of the reaction solution to 100°C, and polycondensate at this temperature for 6 hours. Then, the reaction solution is heated to 180°C, dried under reduced pressure at a pressure of 10 mmHg, and the solvent is devolatilized to obtain a hydroxyl-type novolak resin (A-1-1).

[0095] Synthesis examples A-1-2 to A-3-3

[0096] The synthesis method of the hydroxyl novolak resin is the same as that of Synthesis Example A-1-1, except that Synthesis Examples A-1-2 to A-3-3 change the reactants in the hydroxyl novolak resin (A-1) Types and dosages, the formula is shown in Table 1, and will not be repeated here.

[0097] Preparation of positive phot...

Embodiment 1

[0100] 70 parts by weight of the hydroxy-type novolak resin (A-1-1) obtained in Synthesis Example A-1-1, and 30 parts by weight of the hydroxy-type novolak resin (A-2- 1) 30 parts by weight of 1-[1-(4-hydroxyphenyl)isopropyl]-4-[1,1-bis(4-hydroxyphenyl)ethyl]benzene and 1,2-naphthoquinone Diazide-5-sulfonic acid ester (B-1) (average degree of esterification 85%), 10 parts by weight of tris(4-hydroxyphenyl)methane (C-1), and 300 parts by weight of propylene glycol In the solvent (D-1) of propylene glycol monomethyl ether acetate (PGMEA), the above mixture is dissolved in the solvent by stirring with a shaking stirrer to obtain the positive photosensitive resin composition of the present invention . The obtained positive photosensitive resin composition was evaluated in each of the following evaluation methods, and the results are as shown in Table 2. Among them, the detection methods of discoloration after etching, resolution, and residual film rate will be described later.

Embodiment 2 to 10

[0102] The preparation method of the positive photosensitive resin composition is the same as that of Example 1, except that Examples 2 to 10 change the types and usage of the raw materials in the positive photosensitive resin composition. The formula and test results are shown in Table 2. Show, not repeat them here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com