Single-layer touch screen and manufacturing method thereof and touch screen displayer

A production method and touch screen technology, applied in the direction of instrument, printed circuit manufacturing, electrical digital data processing, etc., can solve the problems of complex implementation, metal bombardment, chamber pollution, etc., to prevent signal interference, prevent sputtering, and ensure cleanliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

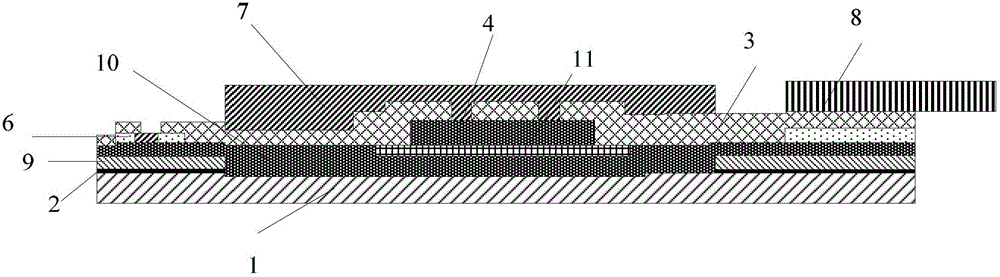

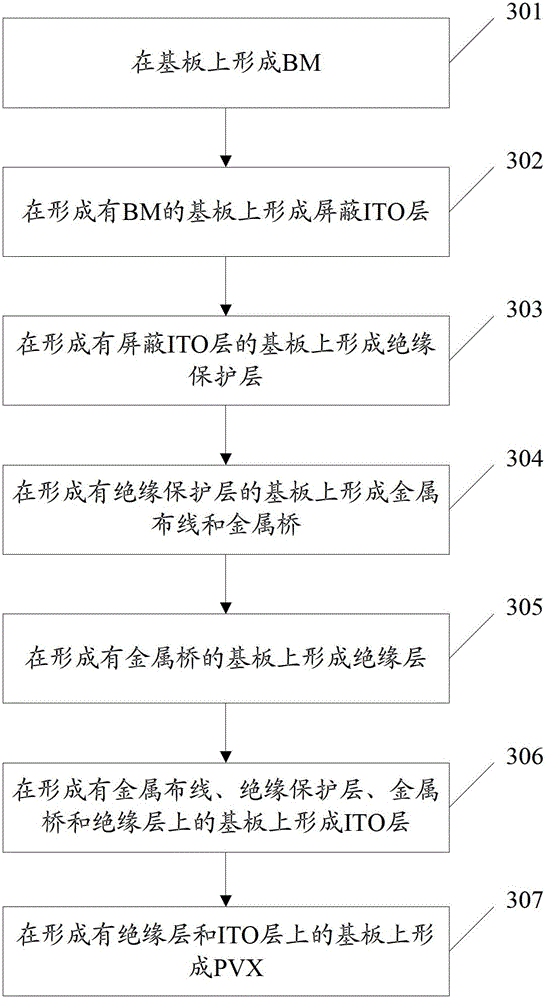

[0034] The basic idea of the present invention is: in order to prevent the sputtering of the metal on the black matrix frame and ensure the cleanliness of the chamber, during the production process of the single-layer touch screen, at least above the black matrix frame and below the metal wiring , set the insulating protective layer.

[0035] Preferably, the shielding indium tin oxide layer and the frame of the black matrix are arranged on the same side of the substrate.

[0036] Preferably, at least one of the indium tin oxide electrode layer and the shielding indium tin oxide layer is disposed above the black matrix frame.

[0037] Further, the indium tin oxide electrode layer and the metal wiring are disposed above the black matrix frame via the insulating protection layer.

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

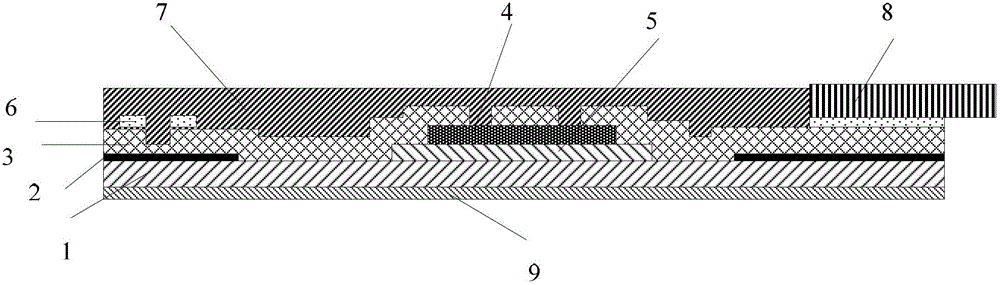

[0039] figure 2 It is a schematic structural diagr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com