Method for producing purified tea extract

A technology of tea extract and manufacturing method, applied in the field of manufacturing refined tea extract, capable of solving problems such as damage to commodity value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

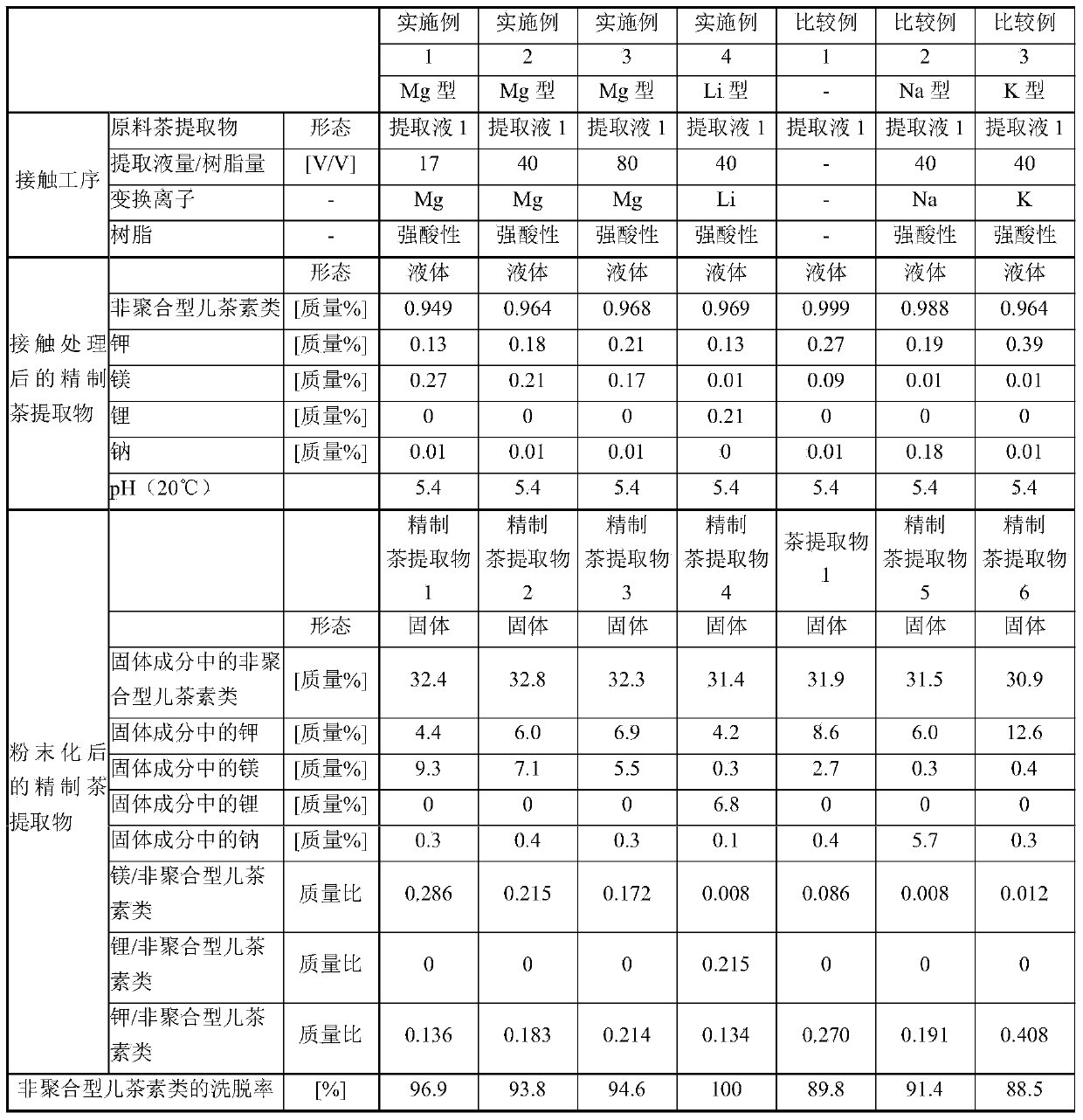

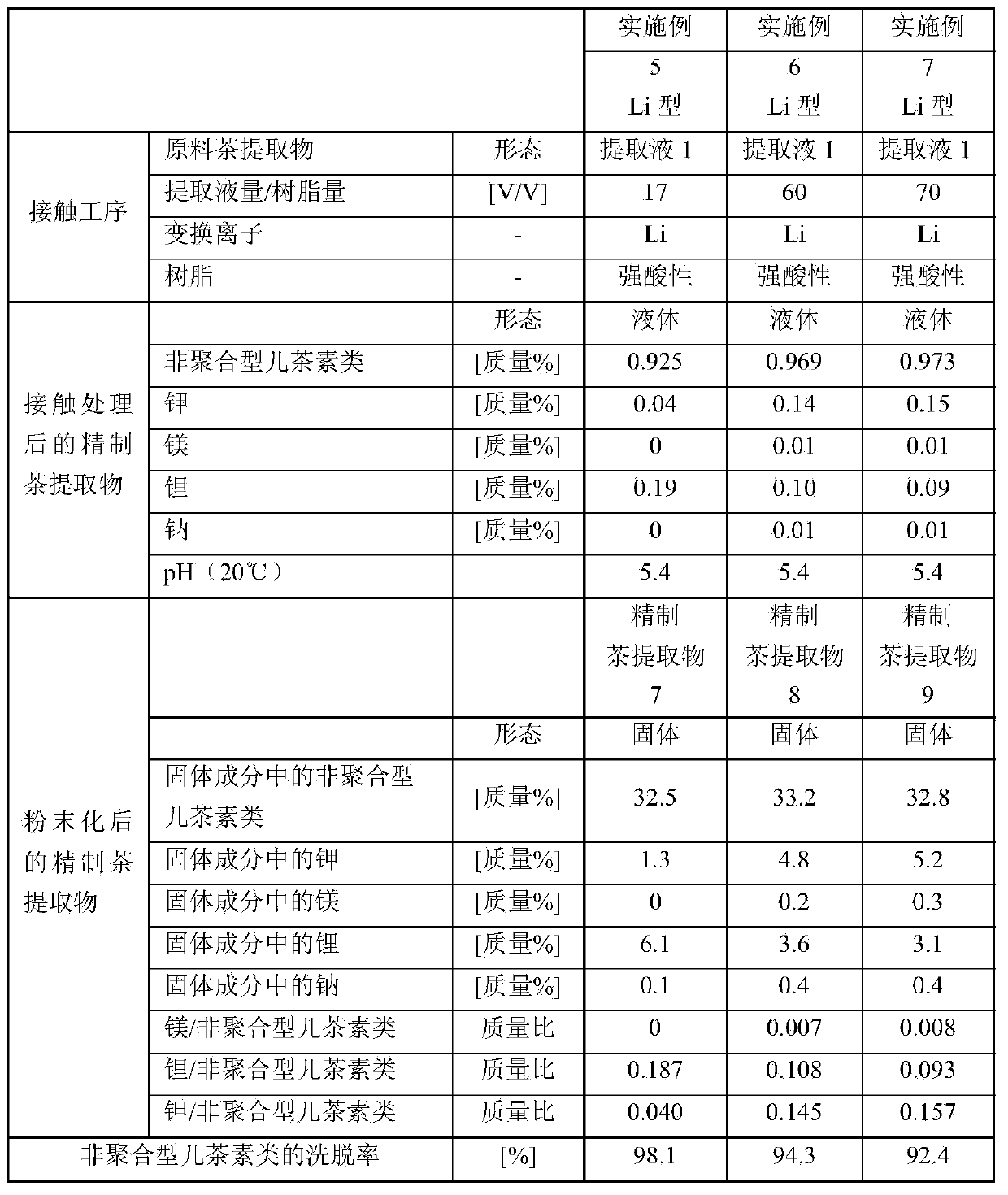

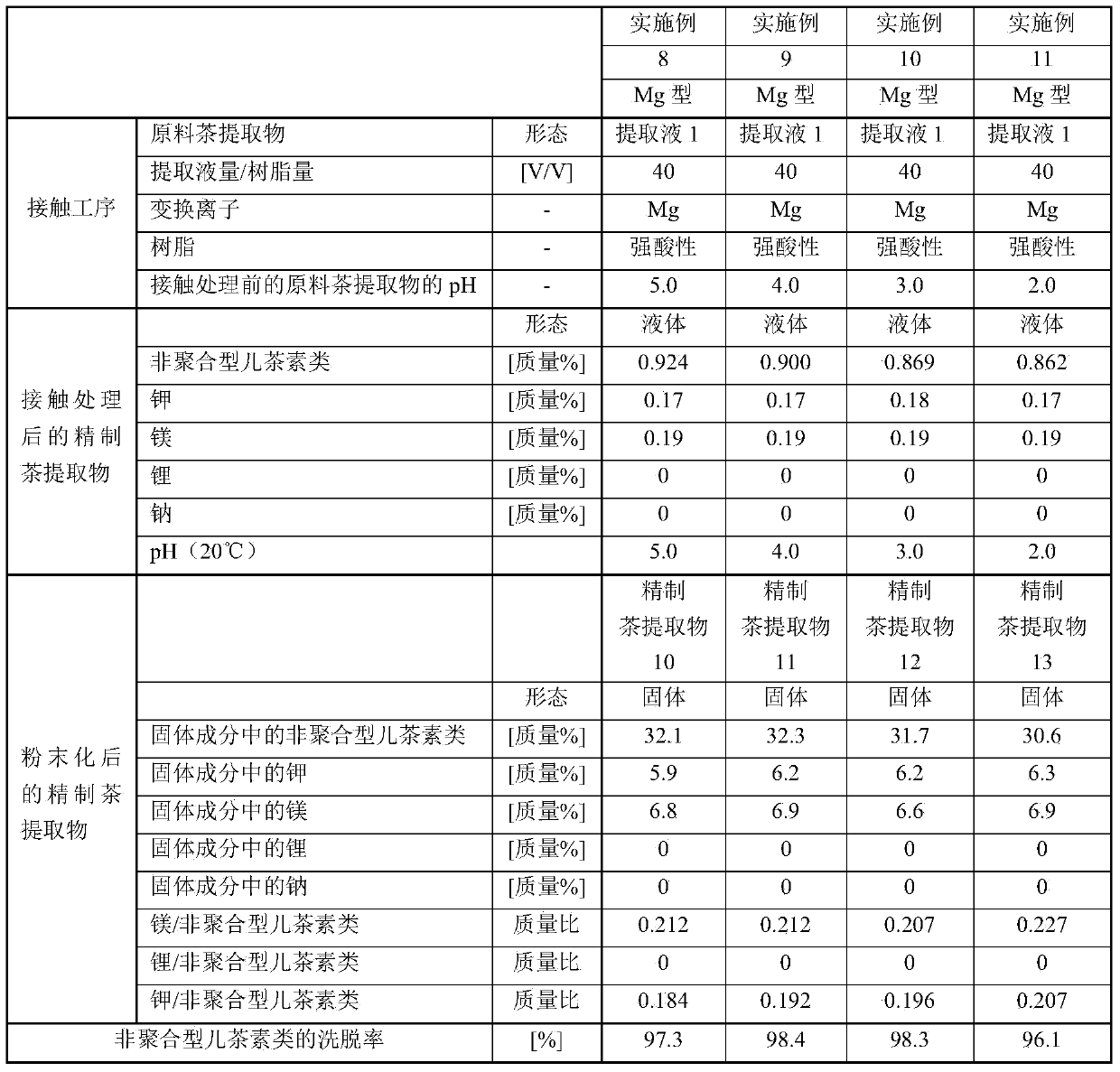

Examples

Embodiment

[0078] 1. Determination of non-polymeric catechins

[0079] Dilute the tea extract, tea extract 1, tea extract 1-3, and refined tea extract 1-16 with distilled water respectively, filter with a filter (0.45 μm), and use a high-performance liquid chromatograph (model SCL- 10AVP, manufactured by Shimadzu Corporation), installed with a packed column for octadecyl introduction liquid chromatography (L-Column TM ODS, 4.6 mmφ × 250 mm, manufactured by the Chemical Substance Evaluation Research Institute), and the column temperature was 35°C The following is carried out by gradient method. A product manufactured by Mitsui Norin was used as a standard product of catechins, and quantified by the calibration curve method. The distilled aqueous solution containing 0.1 mol / L acetic acid was used for the mobile phase A, the acetonitrile solution containing 0.1 mol / L acetic acid was used for the B liquid, the sample injection volume was 20 μL, and the wavelength of the UV detector was 280 ...

manufacture example 1

[0091] Manufacture of Cation Exchange Resins

[0092] 1) Manufacture of magnesium type cation exchange resin

[0093] 10 g of strongly acidic cation exchange resin (Type H, SK1BH, manufactured by Mitsubishi Chemical Corporation) was taken and stirred in 400 g of ion exchanged water containing 20 g of magnesium hydroxide for 40 hours. Next, after filtration, water washing was performed 3 times with 1200 g of ion-exchanged water to manufacture a magnesium type (Mg type) cation exchange resin.

[0094] 2) Manufacture of lithium type cation exchange resin

[0095] 10 g of strongly acidic cation exchange resin (Type H, SK1BH, manufactured by Mitsubishi Chemical Corporation) was taken and stirred in 500 g of 2M lithium hydroxide for 1 hour, and this operation was performed three times. Next, after filtration, water washing was performed 3 times with 1200 g of ion-exchange water, and lithium type (Li type) cation exchange resin was manufactured.

[0096] 3) Manufacture of potassiu...

manufacture example 2

[0101] Preparation of tea extract 1

[0102] 3.23 g of tea extract (32.9% by mass of non-polymer catechins) was taken and dissolved in 967.7 g of ion-exchanged water to prepare tea extract 1 containing 1.0% by mass of non-polymer catechins.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com