Automatic butyl naphthalene sulfonate production device and automatic control method thereof

A technology of sodium butylnaphthalene sulfonate and automatic control, which is applied in the preparation of sulfonic acid, chemical instruments and methods, feeding devices, etc., can solve problems such as accident danger, side reactions, poor product quality, etc. Broad application prospects, the effect of ensuring safe production and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

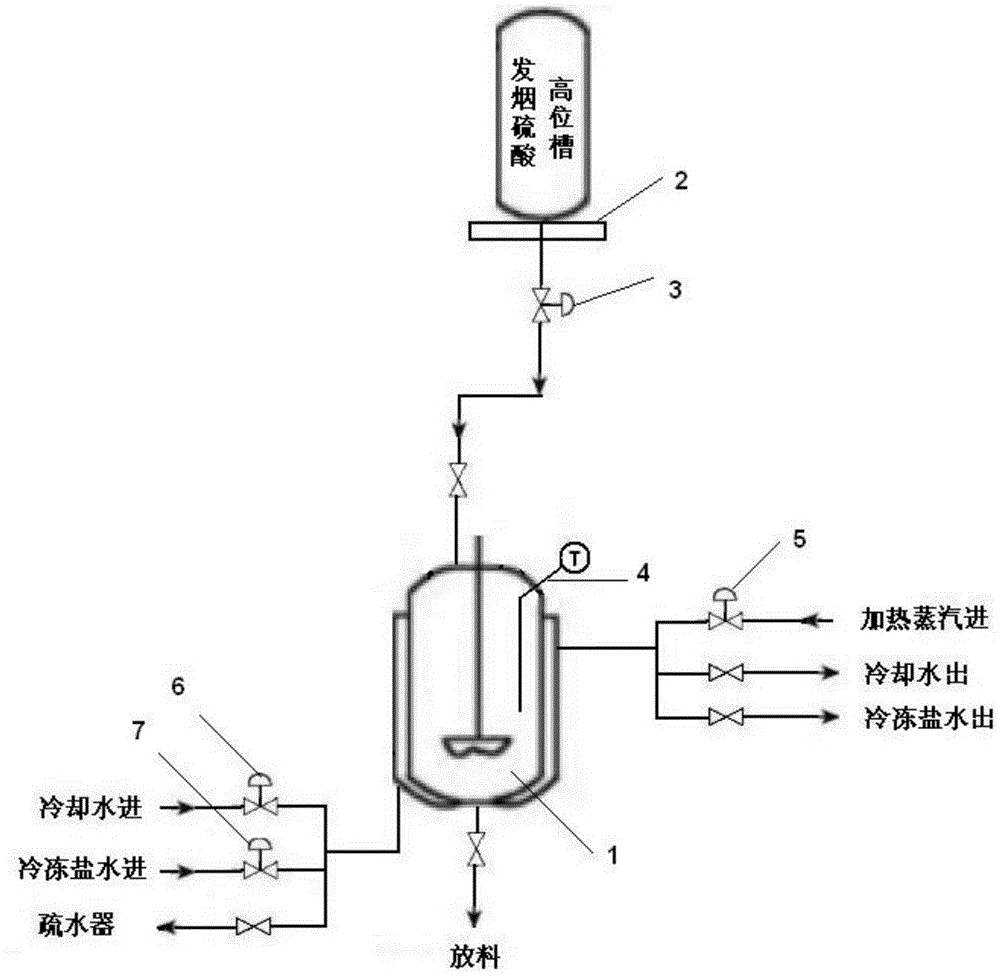

[0021] Such as figure 1 Shown, a kind of sodium butylnaphthalene sulfonate automatic production device of the present invention, it comprises PLC control system (not drawing on the figure), and the oleum head tank and sulfonation reactor 1 connected by pipeline; Sulfonation reaction The kettle jacket is provided with a heating steam pipe or a cooling water pipe or a frozen brine pipe; a weight sensor 2 is provided at the bottom of the oleum head tank, and the weight sensor is connected to the input port of the PLC control system; the fuming sulfuric acid head tank and the sulfonation reaction kettle The connecting pipeline is provided with an oleum control valve 3, which is connected to the output port of the PLC control system; a temperature sensor 4 is provided on the sulfonation reactor, which is connected to the input port of the PLC control system; the heating steam The pipe inlet, the cooling water pipe inlet, and the frozen brine pipe inlet are all provided with control...

Embodiment 2

[0023] The automatic production method of the sodium butylnaphthalene sulfonate automatic production device described in embodiment 1, concrete operation steps are as follows: (1) first add butanol in sulfonation reactor, then refined naphthalene is dissolved therein; Open freezing brine, Turn on the stirring; turn on the automatic control device, when the temperature in the reactor drops below 30°C, the oleum control valve will be automatically opened, and the oleum will be added dropwise for about three hours; after the addition, stir for one hour; add oleum to react During the process, the temperature in the reactor is controlled between 35 and 40°C. (2) Then automatically adjust the steam valve to slowly raise the temperature to 50-55°C and keep it warm for eight hours. (3) Then automatically open the cooling water valve to cool to below 40°C, stand still for 5 hours, and remove the waste acid in the lower layer. (4) Then add water to dilute, transfer to a neutralization ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com