Production process and device of expanded polytetrafluoroethylene board

A technology of polytetrafluoroethylene board and polytetrafluoroethylene, which is applied in the direction of layered products, lamination devices, lamination, etc., can solve the problems that cannot meet the needs of large industrial environments and weak capabilities, and achieve creep resistance and Anti-cold flow characteristics, long service life, easy to cut effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0107] 1) First put the polytetrafluoroethylene dispersed resin into the refrigerator for refrigeration. Preferably, the temperature of refrigeration is below 18°C, and the refrigeration time is more than 12 hours, and then sieved. It should be noted here that the sieve Separation must be performed at the same temperature;

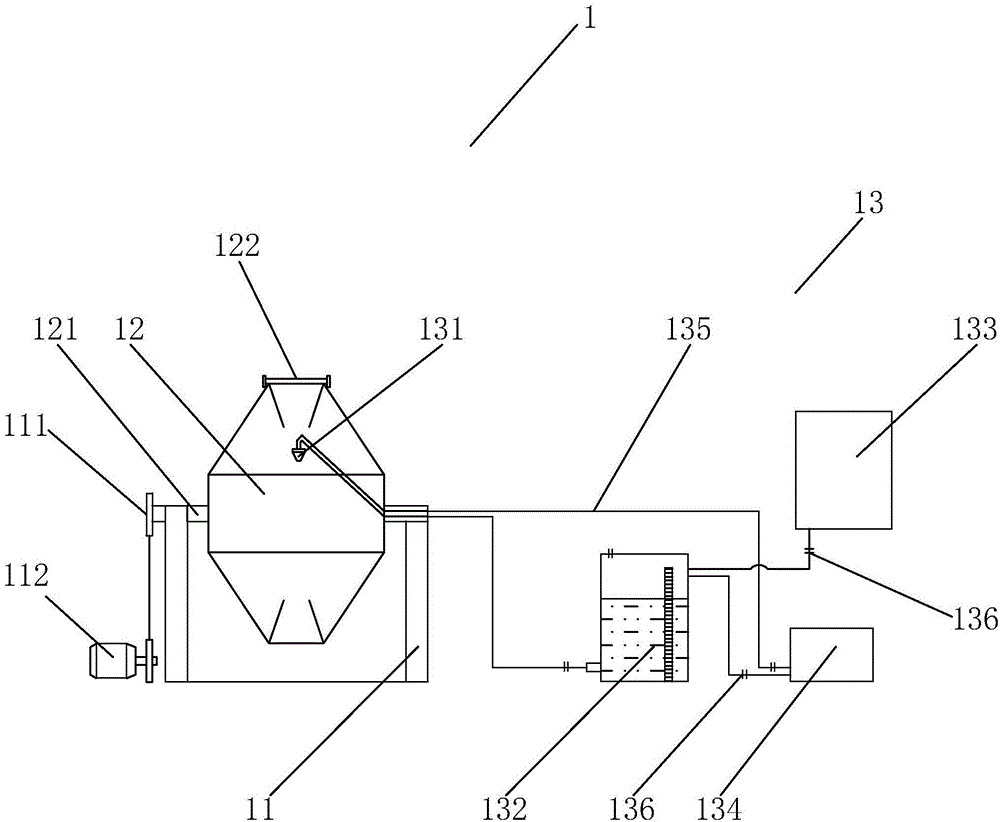

[0108] 2) Weigh the screened polytetrafluoroethylene dispersed resin and pour it into the automatic mixing machine 1. The automatic mixing machine 1 includes a mixing frame 11, a mixing tank 12 and a gas-liquid spraying device 13. Bucket 12 is rotatably erected on the material mixing frame 11 by guide roller 121, as preferably, mixing material tank 12 is double-conical and is made of stainless steel tube, and is provided with inlet and outlet 122 on mixing material tank 12, will The screened polytetrafluoroethylene dispersed resin is poured into the mixing tank 12 from the inlet and outlet 122, and then a certain proportion of auxiliary agent is injected i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com