Preparation method of hexagonal copper selenide nanosheets

A technology of nanosheets and copper selenide, which is applied in the field of preparation of nanomaterials technology, can solve the problems of uncontrollable CuSe reaction process, complex reaction process of CuSe nanosheets, uneven particle size distribution of CuSe nanoparticles, etc., and shorten the reaction time , reduce the chance of recombination, and have strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

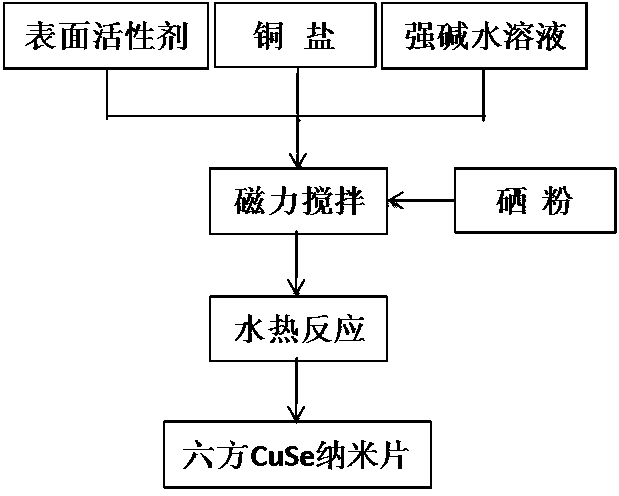

[0020] This embodiment relates to a preparation method of hexagonal copper selenide nanosheets, the specific steps are as follows:

[0021] (1) Add 3 mmol of cuprous chloride and 100 mg of polyvinylpyrrolidone to 50 mL of sodium hydroxide aqueous solution (5 mol / L), stir evenly with magnetic force, and record it as solution A;

[0022] (2) Add 4.5mmol selenium powder to the above solution A under continuous stirring conditions and continue stirring for 30min to obtain solution B;

[0023] (3) Pour solution B into a hydrothermal reaction kettle and place it in an oven, react at 140°C for 2 hours, take out the product after the reaction is completed and clean it with deionized water, and finally obtain hexagonal copper selenide nanosheets, The side length is 600 nm and the thickness is 20 nm.

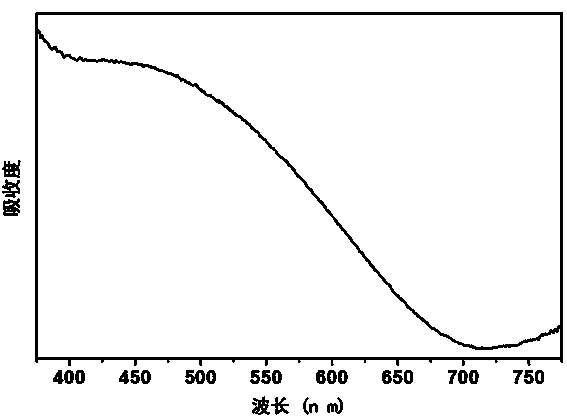

[0024] Experimental process such as figure 1 As shown, the SEM image and absorption spectrum of the prepared product are as figure 2 and image 3 shown.

Embodiment 2

[0026] This embodiment relates to a preparation method of hexagonal copper selenide nanosheets, the specific steps are as follows:

[0027] (1) Add 4 mmol of cuprous iodide and 150 mg of polyvinylpyrrolidone to 50 mL of sodium hydroxide aqueous solution (12 mol / L), stir evenly with magnetic force, and record it as solution A;

[0028] (2) Add 6 mmol of selenium powder to the above solution A under continuous stirring conditions and continue stirring for 30 minutes to obtain solution B;

[0029] (3) Pour solution B into a hydrothermal reaction kettle and place it in an oven, react at 160°C for 1 hour, take out the product after the reaction is completed and clean it with deionized water, and finally obtain hexagonal copper selenide nanosheets, The side length is 610 nm and the thickness is 20 nm. The SEM image of the prepared product is shown in Figure 4 shown.

Embodiment 3

[0031] This embodiment relates to a preparation method of hexagonal copper selenide nanosheets, the specific steps are as follows:

[0032] (1) Add 5 mmol of cuprous chloride and 100 mg of polyvinylpyrrolidone to 50 mL of potassium hydroxide aqueous solution (10 mol / L), stir evenly with magnetic force, and record it as solution A;

[0033] (2) Add 7.5mmol selenium powder to the above solution A under continuous stirring condition and continue stirring for 30min to obtain solution B;

[0034] (3) Pour solution B into a hydrothermal reaction kettle and place it in an oven, react at 100°C for 4 hours, take out the product after the reaction is completed and clean it with deionized water, and finally obtain hexagonal copper selenide nanosheets, The side length is 500 nm and the thickness is 20 nm. The SEM image of the prepared product is shown in Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Side length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com