Graphene transfer method

A transfer method, graphene technology, applied in the direction of graphene, nano-carbon, etc., can solve the problems of affecting the electrical properties of graphene, difficult transfer of graphene, easy residue of adhesive, etc., to achieve large-scale production and improve adhesion , the effect of long transfer period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

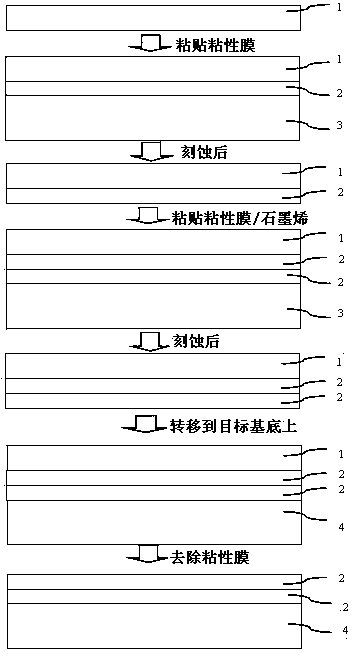

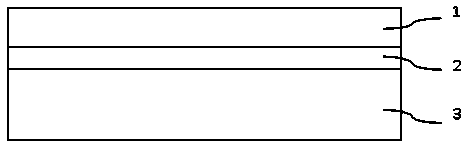

[0043] A method for transferring graphene (bilayer), comprising the steps of:

[0044] (1) Use copper foil as a growth substrate to prepare a graphene layer by vapor phase deposition, and flatten the copper foil with a graphene layer with glass;

[0045] (2a) Attach a silicone adhesive film (adhesive is silica gel, substrate is PET) to the surface of the graphene layer grown on the copper foil by the roll-to-roll method; the graphene layer grown on the copper foil will be attached Put the adhesive film into the ammonium persulfate solution to etch, with the side of the silicone adhesive mold facing up and the side of the copper foil facing down; after 3 minutes, use deionized water and ethanol to clean the surface of the copper foil, the same method, continuous Cleaning 3 times; etching 2h, copper foil is completely removed; then the silica gel adhesive film adhered with graphene layer is taken out from the ammonium persulfate solution, and the silica gel adhesive film adhered...

Embodiment 2

[0052] A method for transferring graphene (5 layers), comprising the steps of:

[0053] (1) Use copper foil as the growth substrate to prepare graphene layer by vapor phase deposition method, and roll the copper foil with graphene layer through roll-to-roll equipment to make the copper foil film very flat;

[0054] (2a) Attach a polysilica gel film (adhesive is silica gel, substrate PI) to the surface of the graphene layer grown on the copper foil by the roll-to-roll method; the graphene layer grown on the copper foil will be attached Put the viscous film into the ferric chloride solution to etch, with the side of the viscous mold facing up and the side of the copper foil facing down; after 5 minutes, clean the surface of the copper foil with deionized water and methanol, and continue cleaning in the same way 3 times; etching for 2h, the copper foil was completely removed; then the polysilica gel sticky film with the graphene layer was taken out from the ferric chloride soluti...

Embodiment 3

[0061] A method for transferring graphene (4 layers), comprising the steps of:

[0062] (1) Use copper foil as the growth substrate to prepare graphene layer by vapor phase deposition method, and roll the copper foil with graphene layer through roll-to-roll equipment to make the copper foil film very flat;

[0063] (2a) Attach an acrylic adhesive film (adhesive is acrylate pressure-sensitive adhesive, substrate is PET) to the surface of the graphene layer grown on the copper foil by the roll-to-roll method; The sticky film of the graphene layer on the copper foil is etched in a copper chloride solution, with the sticky film side up and the copper foil side down; after 5 minutes, clean the copper foil with absolute ethanol and deionized water The same method was used to clean the surface twice continuously; the copper foil was completely removed after etching for 2 hours; The acrylic sticky film of the graphene layer is cleaned, blown dry with nitrogen, and obtains a sticky fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com