Method for transferring graphene film

A graphene film and substrate technology, applied in the field of transfer graphene film, can solve problems such as residual glue, graphene film damage, wrinkles, etc., and achieve the effects of improving cleanliness, reducing wrinkles and damage, and improving integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

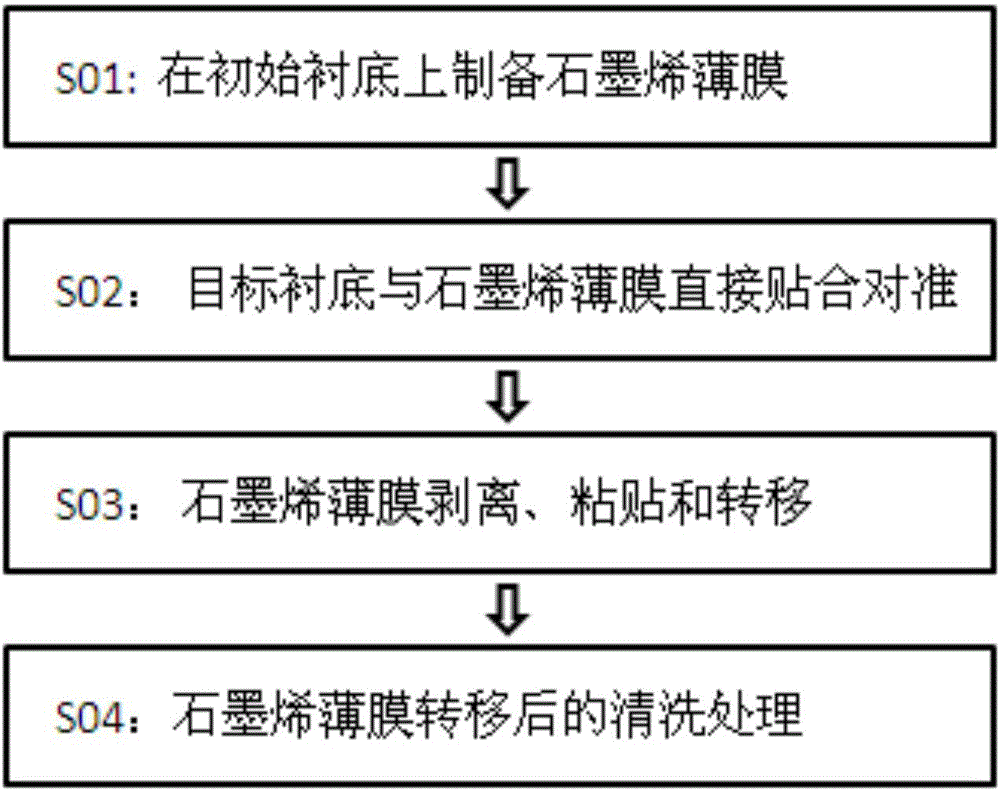

[0042] In this embodiment, the initial substrate is metal, and the graphene film only needs to be aligned in appearance when it is transferred to the target substrate after preparation. In this embodiment, an electrochemical method is used to transfer the graphene film. according to figure 2 steps shown.

[0043] Step S01: preparing a graphene film on an initial substrate. In this embodiment, copper Cu foil is used as the substrate with a thickness of 40 microns. By chemical vapor deposition CVD method, methane CH4 and hydrogen H2 are used as reaction gases to prepare graphene film on copper foil.

[0044] Step S02 : After aligning the graphene film on the copper foil with the target substrate, they are directly pasted together, and the two are fixed together with a clamp 040 . The fixture can be any component capable of fixing the relative positions of the initial substrate and the target substrate. The clamps used in this example are metal clips.

[0045]Step S03: The...

Embodiment 2

[0048] In this embodiment, the graphene film needs to be precisely aligned with the target substrate for transfer. still use figure 2 steps shown.

[0049] Step S01: the initial substrate is copper Cu foil, and the thickness of metallic copper is 40 microns. By chemical vapor deposition CVD, using methane CH4 and hydrogen H2 as reaction gases, a graphene film was prepared on the surface of copper Cu.

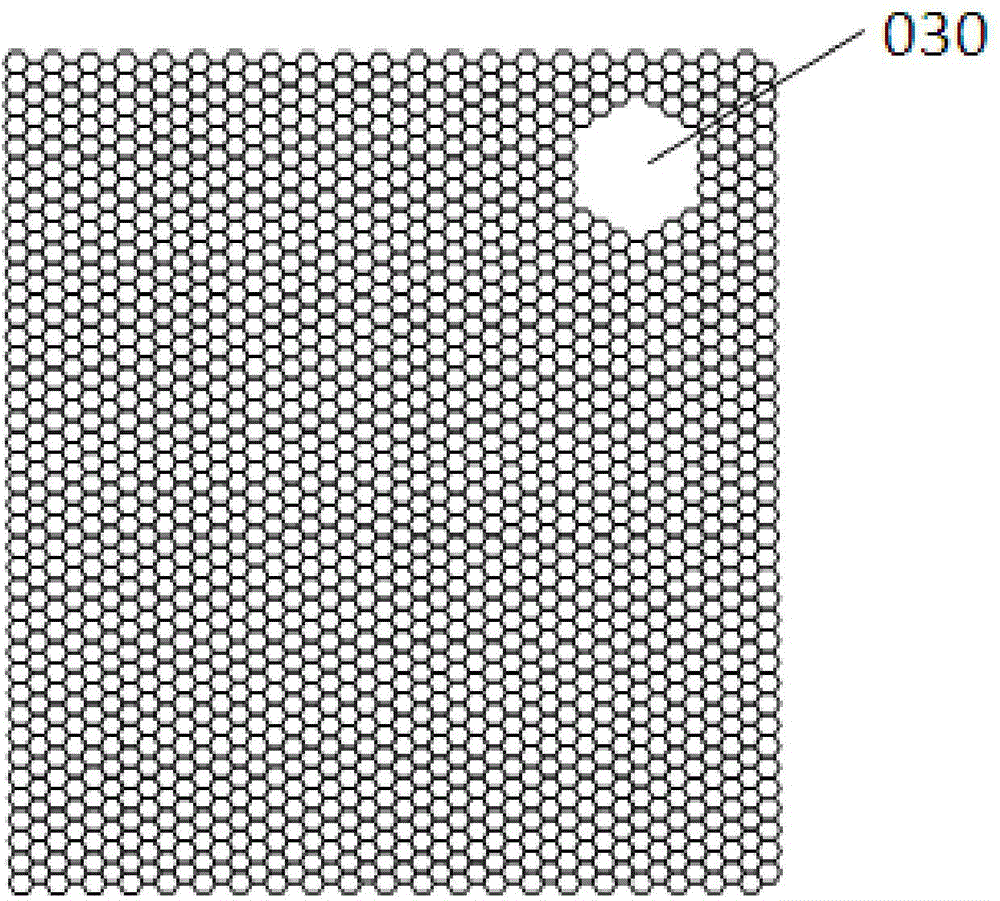

[0050] Step S02: Please refer to image 3 After the graphene film is prepared, artificial defects are formed on the graphene film by photolithography, and the graphene film is anisotropically etched with plasma, and the graphene crystal orientation is precisely formed along the artificial defect. Aligned graphic markers. In this embodiment, hydrogen H2 is used as a precursor, and graphene is anisotropically etched by H-containing plasma, and the etching expands along the artificial defects that have been formed and finally forms regular hexagons along the graphene lattice. ...

Embodiment 3

[0054] The difference from the first embodiment is that the stripping of the graphene film in this embodiment adopts the method of metal corrosion. still use figure 2 steps shown.

[0055] Step 01 / 02: The initial substrate is copper Cu foil, the thickness of metal copper is 40 microns, and the target substrate is glass. Graphene film is prepared on the surface layer of copper foil. Align and fix the copper foil / graphene film and the target substrate. Fixing is done with clamps made of plastic or ceramic.

[0056] Step S03: Put the fixed copper foil / graphene film and the target substrate together into a ferric chloride FeCl3 metal corrosion solution with a concentration of 2.5 mol / L. Etching the metal transfers the graphene film to the target substrate.

[0057] The difference that needs to be pointed out is the cleaning and drying process after the graphene film is transferred to the target substrate in step S04. After the transferred graphene film is rinsed with deioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com