2-ethyl-2-hexenyl hydroximic acid as well as combined collector thereof and application of 2-ethyl-2-hexenyl hydroximic acid and combined collector

A technology of hexenyl hydroxamic acid and combined collectors, applied in solid separation, organic chemistry, flotation, etc., can solve the problems of limited popularization and application, weak collection capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1 Preparation of alkenyl hydroxamic acid combination collector 1 and 2-ethyl-2-hexenyl hydroxamic acid

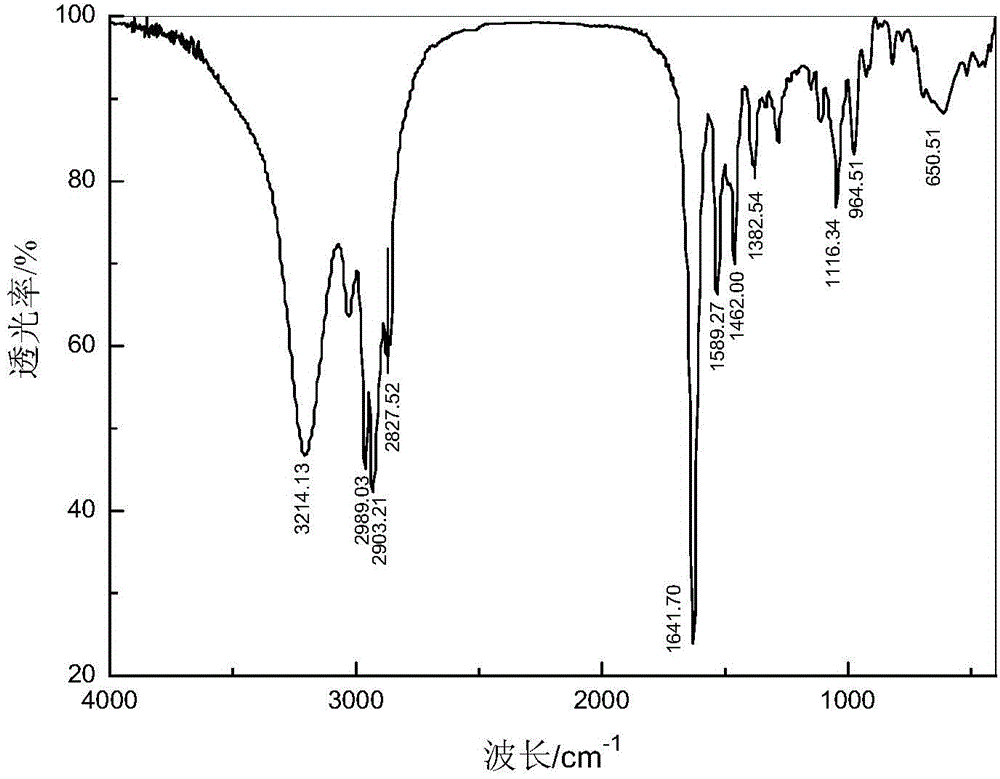

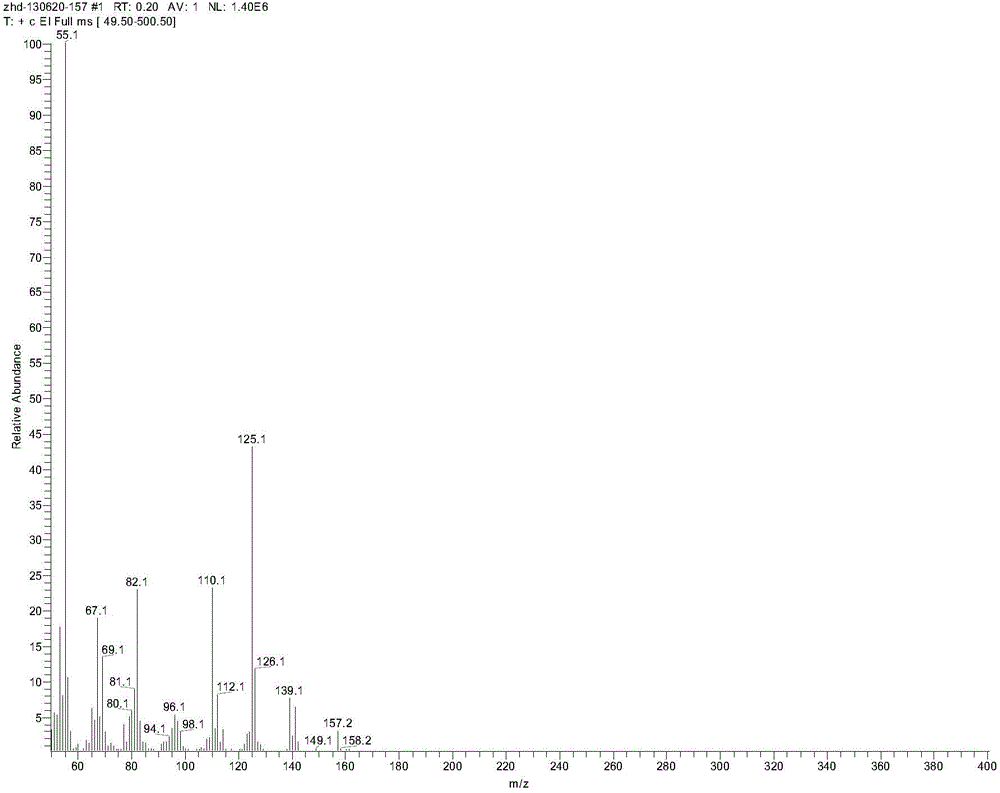

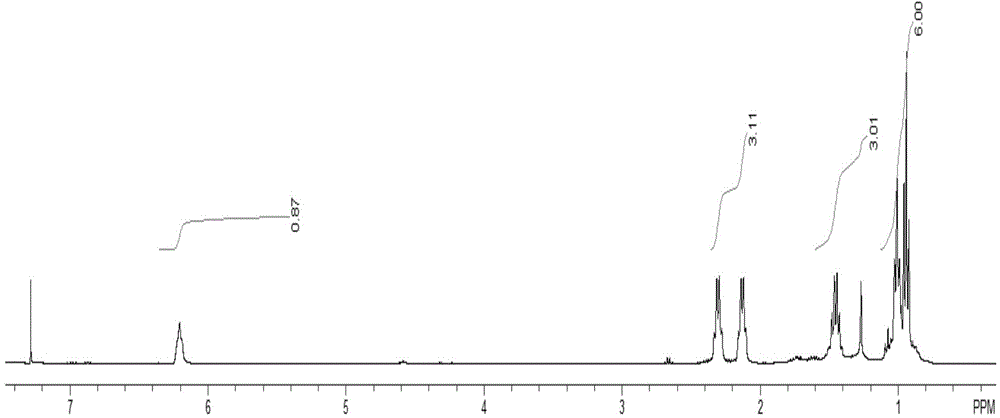

[0041] Add 7.1 parts of 2-ethyl-2-hexenoic acid, 9.6 parts of methanol, and 1.0 parts of concentrated sulfuric acid into a reactor with a stirring device, and react at 80°C for 6 hours to obtain 2-ethyl-2-hexene According to the method of national standard GB / T12717-2007, the esterification rate is 94.32%. Dissolve 3.83 parts of hydroxylamine hydrochloride and 4.4 parts of sodium hydroxide in 50.5 parts of methanol, add 13.8 parts of the 2-ethyl-2-hexenoic acid methyl ester product prepared by the previous step reaction, stir and control the temperature at 50oC, and react 3 hours, distilled to obtain the alkenyl hydroxamic acid combined collector, wherein the mass percentage of 2-ethyl-2-hexenyl hydroxamic acid is 71.2%. The 2-ethyl-2-hexenyl hydroxamic acid obtained by the separation and purification of the combined collector through silica gel column ch...

Embodiment 2

[0042] The preparation of embodiment 2 alkenyl hydroxamic acid combined collector 2

[0043] Add 7.1 parts of 2-ethyl-2-hexenoic acid, 9.6 parts of methanol, and 1.0 parts of dodecylbenzenesulfonic acid into a reactor with a stirring device, and react at 80°C for 6 hours to obtain 2-ethyl -2-hexenyl methyl ester product, the esterification rate is 92.58%. Dissolve 3.83 parts of hydroxylamine hydrochloride and 4.4 parts of sodium hydroxide in 45.8 parts of ethanol, add 13.8 parts of 2-ethyl-2-hexenoic acid methyl ester product prepared by the previous step reaction, stir and control the temperature at 50oC, reaction 3 Hours, distilled to obtain alkenyl hydroxamic acid combined collector, wherein the mass percentage of 2-ethyl-2-hexenyl hydroxamic acid is 73.5%.

Embodiment 3

[0044] The preparation of embodiment 3 alkenyl hydroxamic acid combined collector 3

[0045] Add 7.1 parts of 2-ethyl-2-hexenoic acid, 8 parts of methanol, and 1.0 parts of concentrated sulfuric acid into a reactor with a stirring device, and react at 80°C for 6 hours to obtain 2-ethyl-2-hexene Methyl ester product, the esterification rate is 90.65%. Dissolve 3.83 parts of hydroxylamine hydrochloride and 4.4 parts of sodium hydroxide in 48 parts of ethanol, add 13.8 parts of the 2-ethyl-2-hexenoic acid methyl ester product prepared in the previous step reaction, stir and control the temperature at 50oC, and react for 3.5 hours , Distilled to obtain the alkenyl hydroxamic acid combined collector, wherein the mass percentage of 2-ethyl-2-hexenyl hydroxamic acid is 71.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com