Novel antibacterial mould-proof and moisture-proof artificial board decorative paper and preparation method thereof

An antibacterial, mildew-proof, wood-based panel technology, applied in papermaking, textiles, papermaking, paper, etc., can solve the problems of strong photosensitive effect, easy oxidation and discoloration, affecting the appearance of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

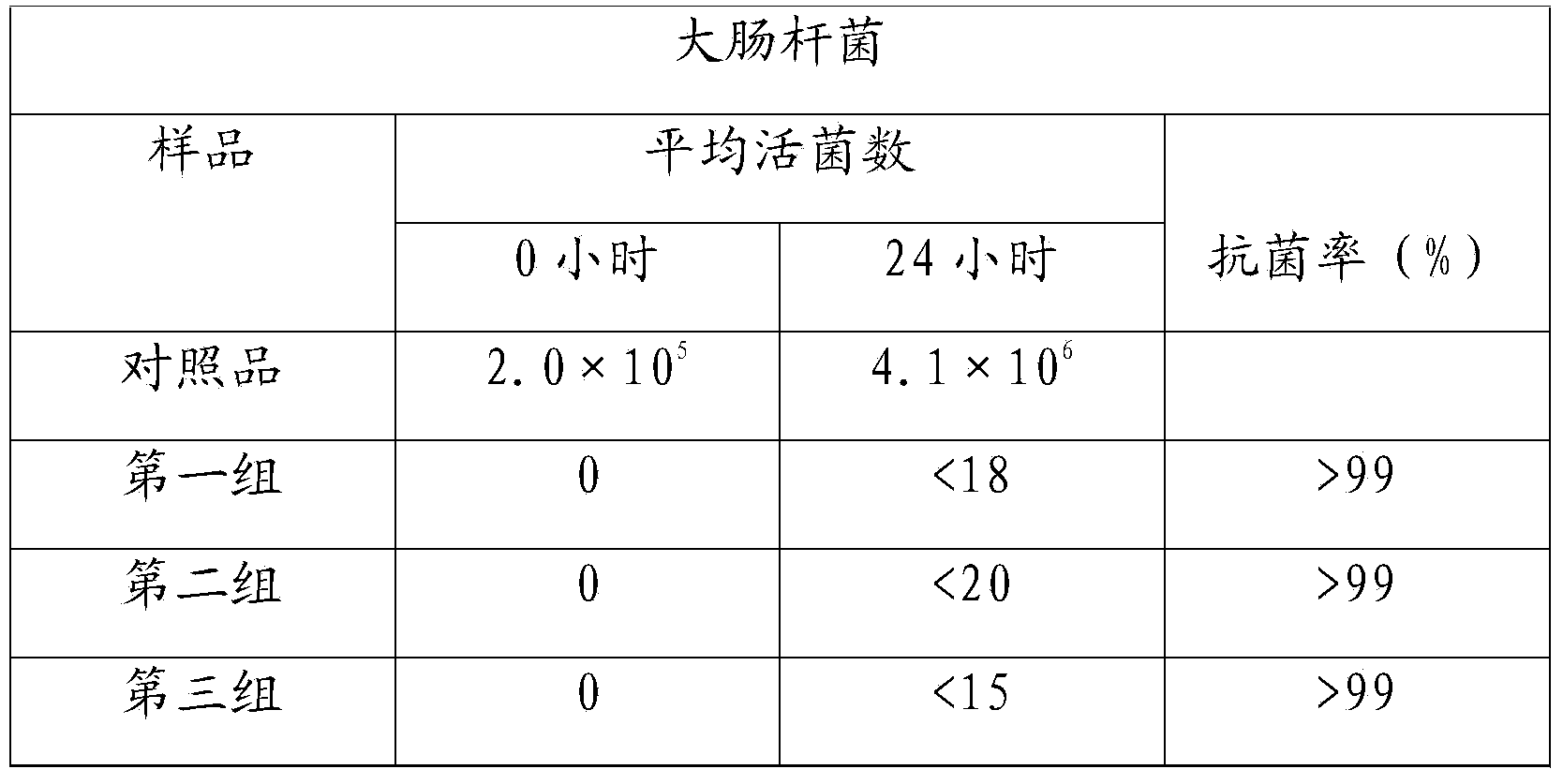

Examples

Embodiment 1

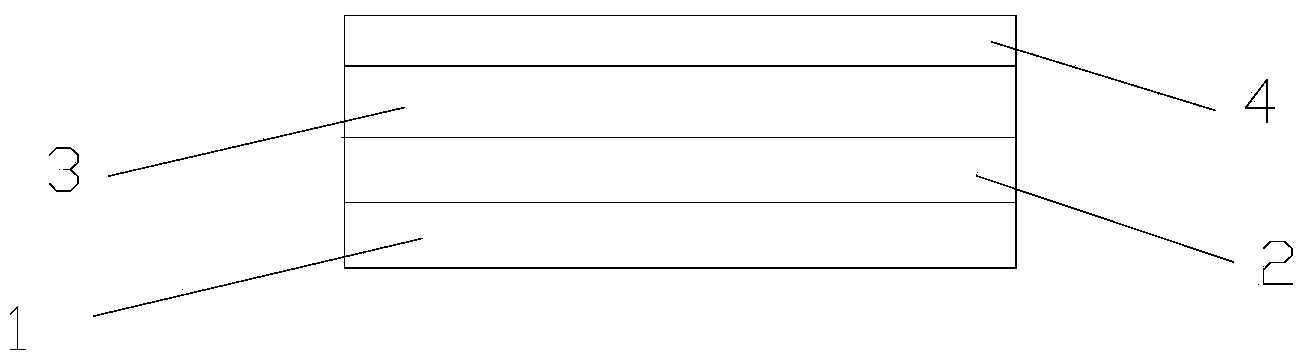

[0038] combine figure 1 . A new type of antibacterial, mildew-proof and moisture-proof wood-based decorative paper, including a base paper 1, and a composite layer compounded on the base paper, the composite layer is sequentially composed of a first resin layer 2 and a second resin layer from bottom to top. Layer 3 and antibacterial and mildew-proof layer 4; Described first resin layer is low-formaldehyde urea-formaldehyde resin layer; Described second resin layer is melamine resin layer; Described antibacterial and mildew-proof layer is made of organic antibacterial, antifungal agent and inorganic antibacterial, Made with antifungal agent.

[0039] The antibacterial, anti-mildew and moisture-proof novel wood-based panel decorative paper is prepared by the following method:

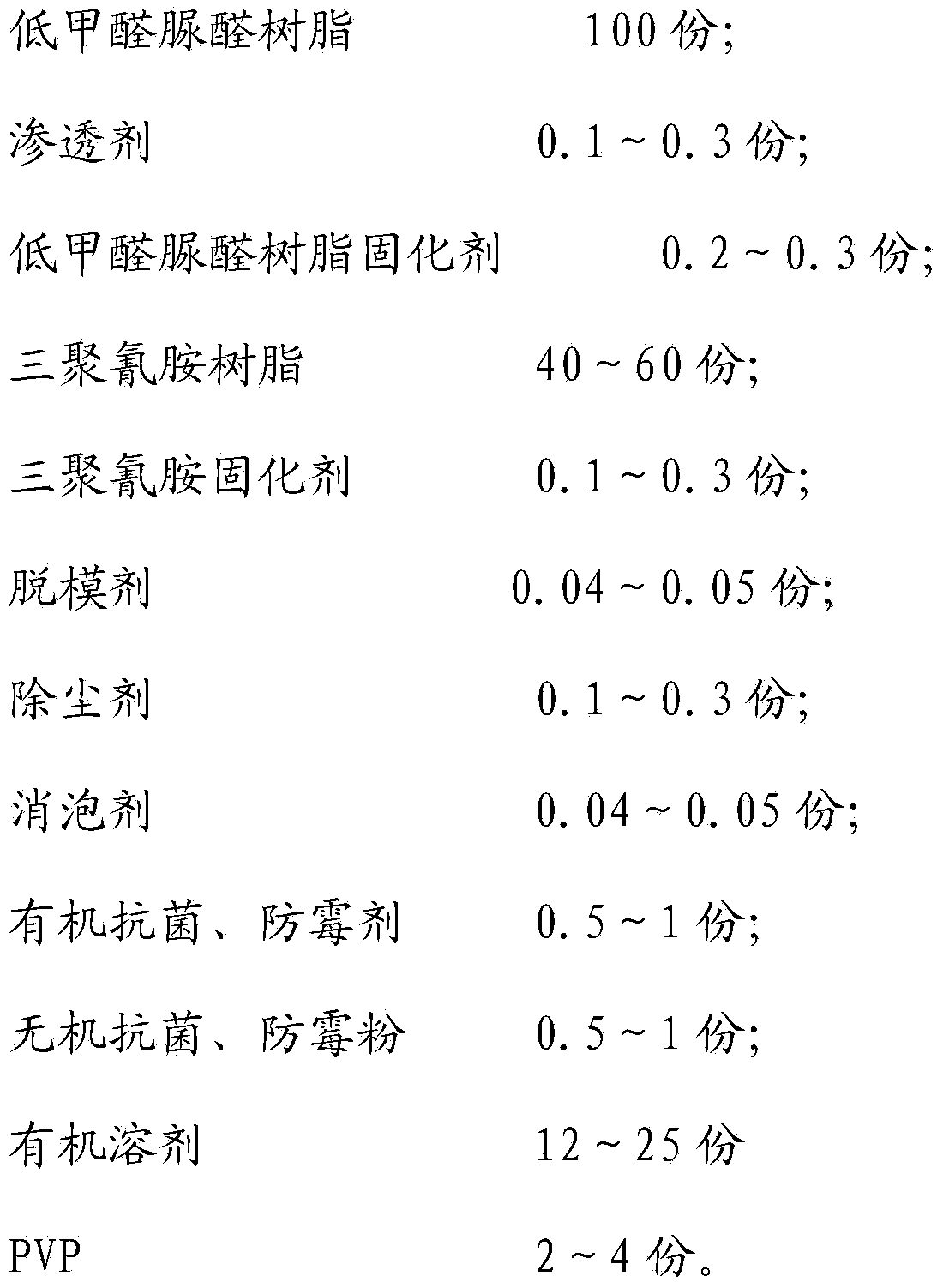

[0040] Take wood grain paper (i.e. base paper), and weigh the following components by weight: 100 parts of low-formaldehyde urea-formaldehyde resin; 0.1 part of penetrant; 0.2 part of low-formaldehyde u...

Embodiment 2

[0050] A new type of antibacterial, mildew-proof and moisture-proof wood-based decorative paper, including a base paper, which also includes a composite layer compounded on the base paper, and the composite layer is sequentially composed of a first resin layer, a second resin layer and Antibacterial and antifungal layer; the first resin layer is a low-formaldehyde urea-formaldehyde resin layer; the second resin layer is a melamine resin layer; the antibacterial and antifungal layer is made of organic antibacterial and antifungal agents and inorganic antibacterial and antifungal agents become.

[0051] The antibacterial, anti-mildew and moisture-proof novel wood-based panel decorative paper is prepared by the following method:

[0052] Get the wood grain paper (i.e. the base paper), and weigh the following components by parts by weight: 100 parts of low-formaldehyde urea-formaldehyde resin; 0.3 part of penetrating agent; 0.3 part of low-formaldehyde urea-formaldehyde resin curi...

Embodiment 3

[0062] A new type of antibacterial, mildew-proof and moisture-proof wood-based decorative paper, including a base paper, which also includes a composite layer compounded on the base paper, and the composite layer is sequentially composed of a first resin layer, a second resin layer and Antibacterial and antifungal layer; the first resin layer is a low-formaldehyde urea-formaldehyde resin layer; the second resin layer is a melamine resin layer; the antibacterial and antifungal layer is made of organic antibacterial and antifungal agents and inorganic antibacterial and antifungal agents become.

[0063] The antibacterial, anti-mildew and moisture-proof novel wood-based panel decorative paper is prepared by the following method:

[0064] Get the wood grain paper (i.e. the base paper), and weigh the following components by parts by weight: 100 parts of low-formaldehyde urea-formaldehyde resin; 0.2 part of penetrating agent; 0.26 part of low-formaldehyde urea-formaldehyde resin cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com