Horizontal dual-polar pipe type colloid storage battery and preparation method thereof

A colloidal battery and colloidal electrolyte technology, applied in the direction of lead-acid batteries, lead-acid battery electrodes, lead-acid battery construction, etc., can solve the problems of difficult formation, uneven battery temperature, poor battery consistency, etc., to reduce the overall weight, The effect of slowing down the corrosion rate and improving the charge-discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

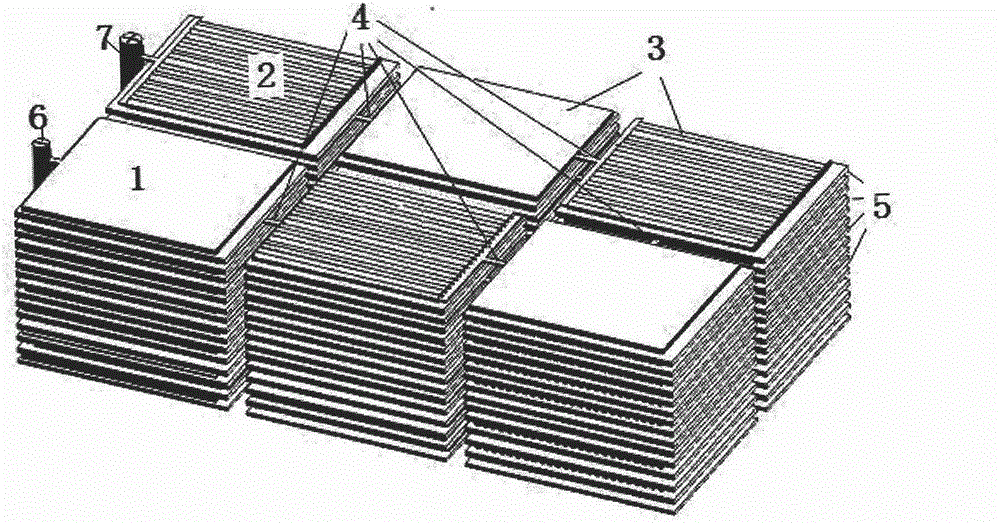

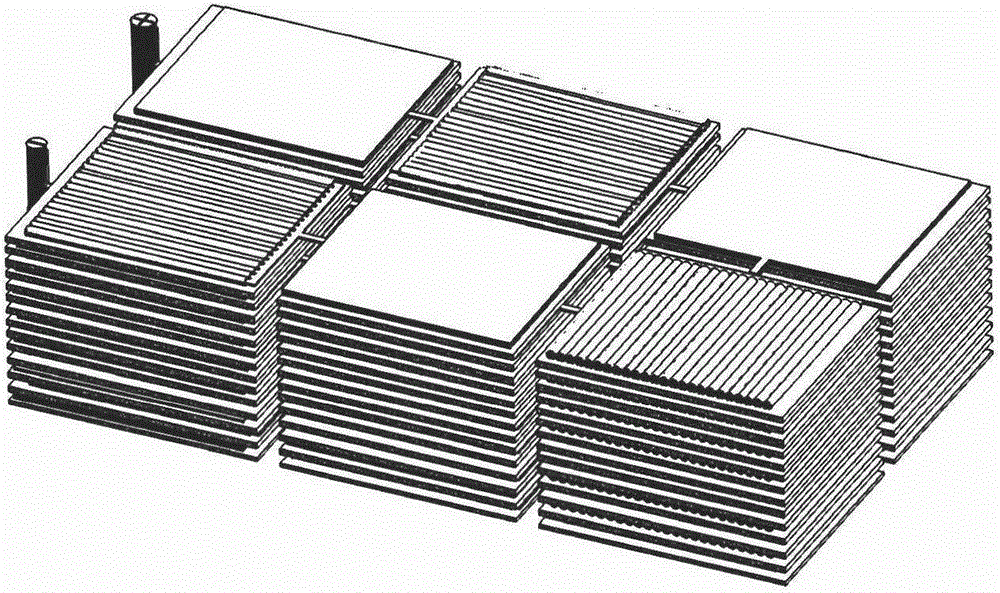

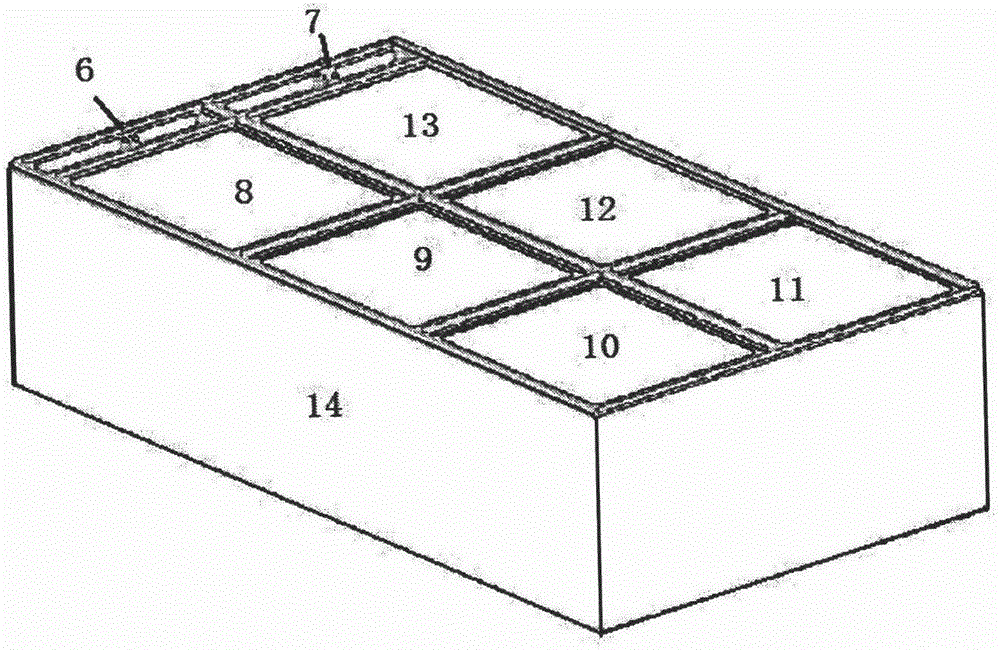

[0039] In one embodiment of the present invention, a 12V horizontal bipolar gel battery is prepared. Such as figure 1, 2 , 3, first lay a piece of negative unipolar sheet 1 horizontally in the battery cell 8 where the negative terminal 7 is located, and then add horizontal bipolar sheets 3 in the adjacent cells 9 and 10, and the positive end of the bipolar sheet is located at In cell 9, the negative end is located in cell 10, and then another horizontal bipolar sheet 3 is added to cells 11 and 12. As mentioned above, the positive and negative electrodes can be alternated; A piece of tubular positive monopole sheet 2 is spread in the cell 13 . So far, the first layer or the bottom pole piece of the horizontal bipolar gel battery has been assembled;

[0040] Next, add one deck of AGM diaphragm 5 on the pole piece in each cell 8-13, lay the first diaphragm layer;

[0041] Then, lay up the second layer of bipolar sheets, and add horizontal bipolar sheets 3 in the single cells ...

Embodiment 2

[0045] In another embodiment of the present invention, a 6V horizontal bipolar gel battery is prepared, such as Figure 5 Shown is a side view of another electrode assembly of a horizontal bipolar battery. For a single cell at the current lead-out end, four tubular negative unipolar sheets 1 and three tubular positive unipolar sheets 2 are used for assembly. . Its assembly operation is basically the same as that described in Example 1, the difference is that the pole plates of the bottom and the top layer are all composed of a single negative plate (or positive plate) and a negative pole end (or positive pole end) of a bipolar plate, and the opposite positive and negative poles Add one deck of PVC separators 5 between them, and positive and negative are stacked alternately. The horizontal bipolar sheets 3 between adjacent cells are connected by the positive and negative vertical connecting strips 19 of the bipolar sheets to form a horizontal bipolar sheet group to evenly dist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com