Technology for cultivating edible fungi by straw wood manufacturing

A technology of edible fungi and straw, applied in application, fertilizer mixture, gardening, etc., can solve the problems of environmental pollution and improper treatment, and achieve the effect of reasonable physical space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

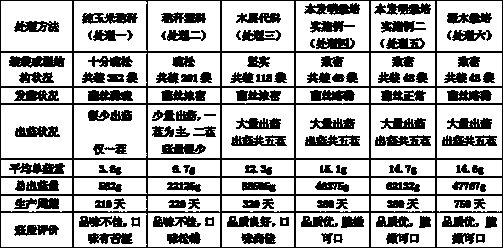

Embodiment 1

[0026] Example 1: Raw Meal Cultivation Technology Made of Straw

[0027] This technology of straw wood making and cultivation of edible fungi comprises the following steps:

[0028] The first step is the selection of raw materials. Take the dried straw and put it into the forage grinder to crush it into a raw material straw with a length of 3mm. Take 100 parts of raw material straw and carry out different proportions according to different crops. The dry material of general crop straw For example, bean stalks, corn stalks, and cotton stalks, the proportion of these crops is to add 5 parts of bran, 5 parts of cottonseed hulls, 1.5 parts of gypsum, and 30 parts of water into the mixer and mix well;

[0029] The second step, straw pressing: put the mixed mixed raw materials into the straw pressing machine for pressing operation, and press them into short wooden sticks or imitation wood blocks with a diameter of 90mm and a length of 400mm, with a density of 0.8g / cm3 and a water co...

Embodiment 2

[0036] Embodiment 2: Straw wood-making clinker cultivation technology

[0037] This technology of straw wood making and cultivation of edible fungi comprises the following steps:

[0038] The first step is the selection of raw materials. Take the dried straw and put it into the forage grinder to crush it into raw material straw with a length of 10mm. Take 100 parts of raw material straw and carry out different proportions according to different crops. The dry material of general crop straw For example, bean stalks, corn stalks, and cotton stalks, the proportion of these crops is to add 5 parts of bran, 5 parts of cottonseed hulls, 1.5 parts of gypsum, and 30 parts of water into the mixer and mix well;

[0039]The second step, straw pressing: put the mixed mixed raw materials into the straw pressing machine for pressing operation, and press them into short wooden sticks or imitation wood blocks with a diameter of 90mm and a length of 400mm, with a density of 0.8g / cm3 and a wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com