Nutritional meal replacement powder suitable for crowd with hyperglycemia and preparation method thereof

A technology for meal replacement powder and high blood sugar, applied in the field of meal replacement powder, can solve the problems of blood sugar fluctuation and aggravate the risk of hyperglycemia, and achieve the effects of convenient eating, good taste and rich nutrition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

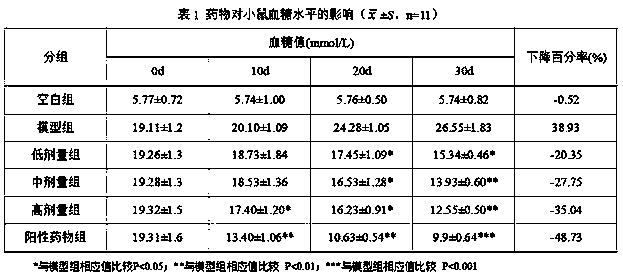

Image

Examples

Embodiment 1

[0023] (1) Weighing: Dietary fiber powder 75Kg (of which, oat flour 15Kg, buckwheat flour 15Kg, konjac flour 25Kg, barley flour 5Kg, arrowroot powder 5Kg, soybean flour 10Kg), fruit and vegetable powder 15Kg (among them, mulberry powder 5Kg, cucumber powder 5Kg, citrus powder 5Kg), mulberry leaf extract 1Kg (of which the alkaloid content is 85%), maltodextrin 5Kg, stevioside 0.5Kg, hydrolyzed whey protein 3Kg, multivitamin 0.3Kg, multimineral 0.2Kg. Place the weighed raw materials in a three-dimensional multi-directional motion mixer and mix them evenly.

[0024] (2) Grind the above-mentioned mixed materials, pass through a 60-mesh sieve, and pack them into individual small-package products.

[0025] (3) Use microwave drying and sterilization equipment to carry out microwave drying and sterilization treatment on the product, and after cooling to room temperature, put it into the outer packaging, which is the finished product. The microwave drying and sterilization treatment c...

Embodiment 2

[0027] (1) Weighing: Dietary fiber powder 60Kg (of which, oat flour 10Kg, buckwheat flour 15Kg, konjac flour 10Kg, barley flour 10Kg, arrowroot powder 10Kg, soybean powder 5Kg), fruit and vegetable powder 22.5Kg (among them, mulberry powder 7.5Kg, Cucumber powder 5Kg, citrus powder 5Kg, green apple powder 5Kg), mulberry leaf extract 3Kg (of which alkaloid content is 50%), maltodextrin 8Kg, stevioside 1.0Kg, hydrolyzed whey protein 4Kg, multivitamin 1Kg, compound Minerals 0.5Kg. Place the weighed raw materials in a three-dimensional multi-directional motion mixer and mix them evenly.

[0028] (2) Grind the above-mentioned mixed materials, pass through a 60-mesh sieve, and pack them into individual small-package products.

[0029] (3) Use microwave drying and sterilizing equipment to carry out microwave drying and sterilizing treatment on the product, after cooling to room temperature, put it into the outer packaging. Microwave drying and sterilization treatment conditions are...

Embodiment 3

[0031] (1) Weighing: Dietary fiber powder 45Kg (among them, oat flour 10Kg, buckwheat flour 15Kg, konjac flour 10Kg, barley flour 10Kg), fruit and vegetable powder 30Kg (among them, mulberry powder 10Kg, cucumber powder 10Kg, green apple powder 10Kg), Mulberry leaf extract 5Kg (of which the alkaloid content is 10%), maltodextrin 10Kg, stevioside 1.5Kg, hydrolyzed whey protein 6Kg, multivitamin 1.5Kg, and multimineral 1.0Kg. Place the weighed raw materials in a three-dimensional multi-directional motion mixer and mix them evenly.

[0032] (2) Grind the above-mentioned mixed materials, pass through a 60-mesh sieve, and pack them into individual small-package products.

[0033] (3) Use microwave drying and sterilizing equipment to carry out microwave drying and sterilizing treatment on the product, after cooling to room temperature, put it into the outer packaging. The microwave drying and sterilization treatment conditions are as follows: the microwave power is 100kW, the micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com