A preparing method of a rare earth catalytic cracking double-metal deactivator

A catalytic cracking, rare earth element technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

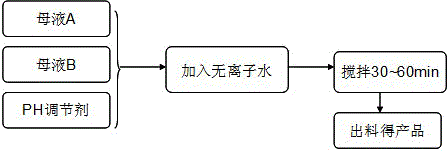

[0037] See Figure 1 to Figure 3 , a kind of preparation method of rare earth element catalytic cracking double metal passivator, concrete steps are:

[0038] A. Mix and stir 300-600kg of mother liquor A, 50-150kg of mother liquor B and 5-20kg of pH regulator;

[0039] B. 30-80kg of deionized water, stirred for 30-60 minutes and discharged.

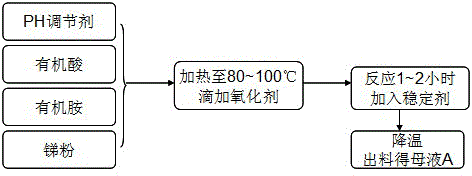

[0040] The preparation steps of mother liquor A are:

[0041] a. Add 6-20kg of pH regulator, 10-35kg of organic acid, and 20-80kg of organic amine into a 500kg reaction flask, and stir for 10 minutes;

[0042] b. Add 80-120kg of antimony powder, continue to increase the temperature by 80-100℃, add 100-170kg of oxidant dropwise;

[0043] c. Condensation and reflux for 1 to 2 hours,

[0044] d. Add 15-35 kg of stabilizer, stir to cool down to room temperature, and discharge to obtain mother liquor A.

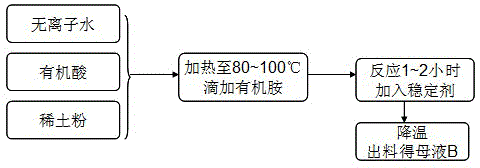

[0045] The preparation steps of mother liquor B are:

[0046] a. Add 100-150kg of rare earth powder, 100-140kg of organic acid, 100-20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com