Continuous type traction power supply system based on multilevel converters connected in parallel

A traction power supply system, traction power supply technology, applied in the direction of conversion equipment, power lines, transportation and packaging for intermediate conversion to DC, can solve the problem that multi-level three-phase-single-phase converters are difficult to achieve in existing substations To achieve the effect of facilitating modularization and large-scale production, improving reliability and redundancy, and increasing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

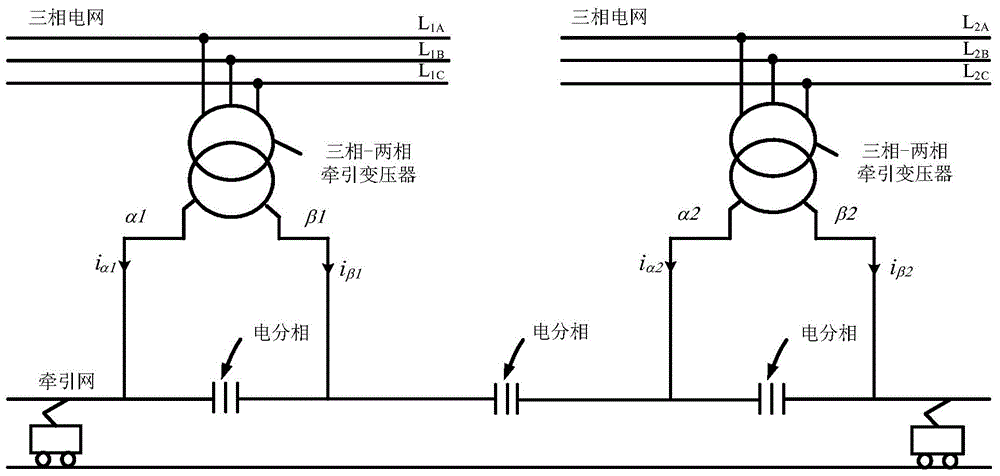

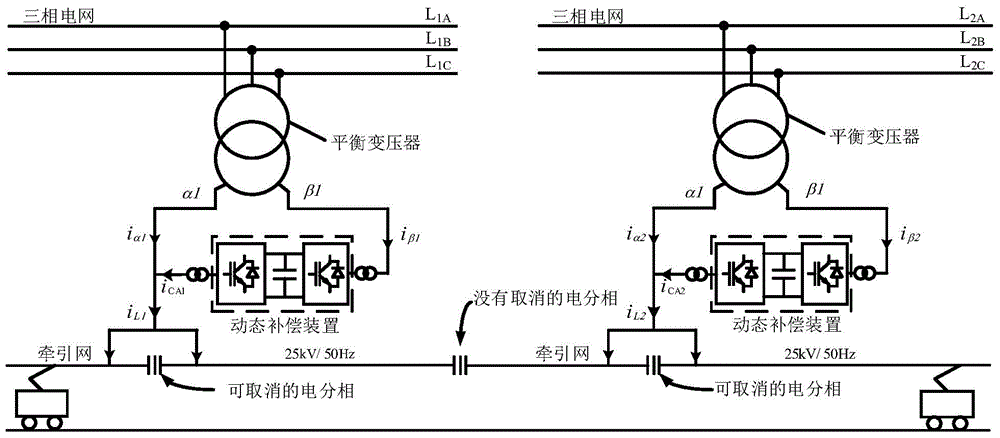

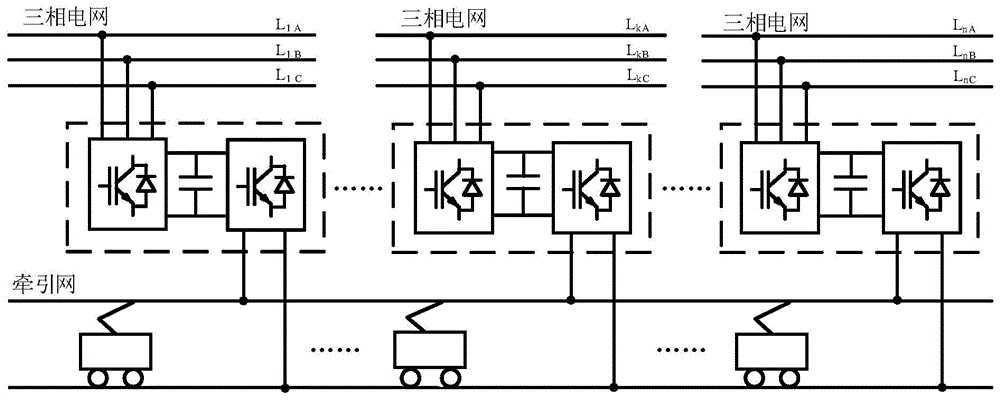

[0026] Figure 4 A through-type traction power supply system based on parallel connection of multi-level converters proposed by the present invention, each substation consists of an input step-down transformer connected to the three-phase power grid, and more than one parallel multi-voltage transformer connected to its output terminal. It consists of a power electronic conversion device for a flat three-phase-single-phase AC-DC-AC converter, and an output step-up transformer connecting the converter and the traction network. The substation is a controllable voltage source, and the traction networks of adjacent substations are directly connected to form a through traction power supply network, which outputs the AC voltage and current required by loads such as locomotives. Considering the long distance between substations and high reli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com