MEMS (Micro Electro Mechanical System) infrared sensor based on film bulk acoustic resonator and preparation method of MEMS infrared sensor

An infrared sensor and thin-film bulk acoustic wave technology, applied in the field of microelectronics, can solve the problems of slow heating and cooling, low detection sensitivity, and narrow detection band, and achieve the effects of no refrigeration, high sensitivity, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are only used to more clearly illustrate the technical solution of the present invention.

[0028] 1. Preparation of MEMS infrared sensor based on thin film bulk acoustic resonator

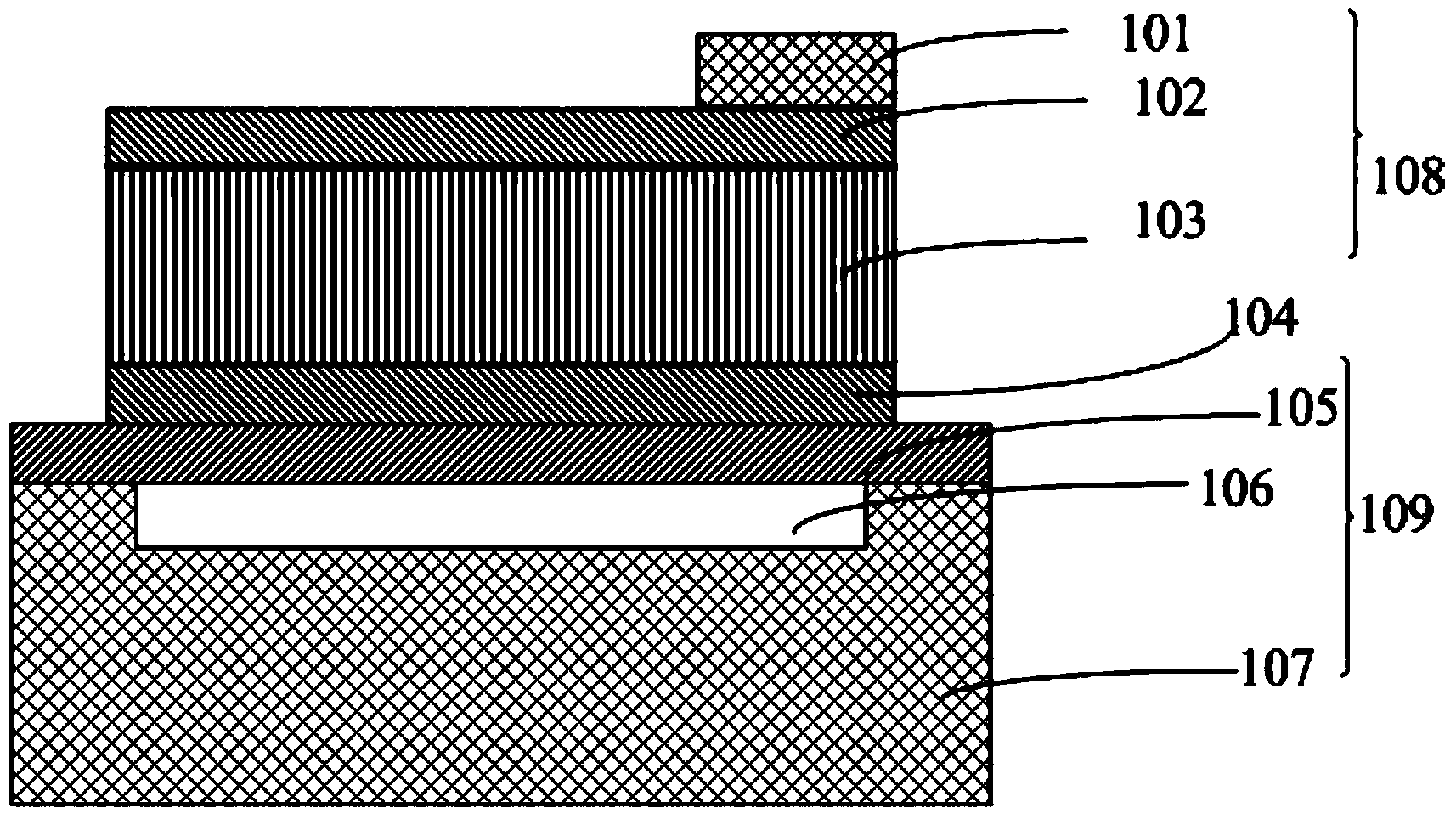

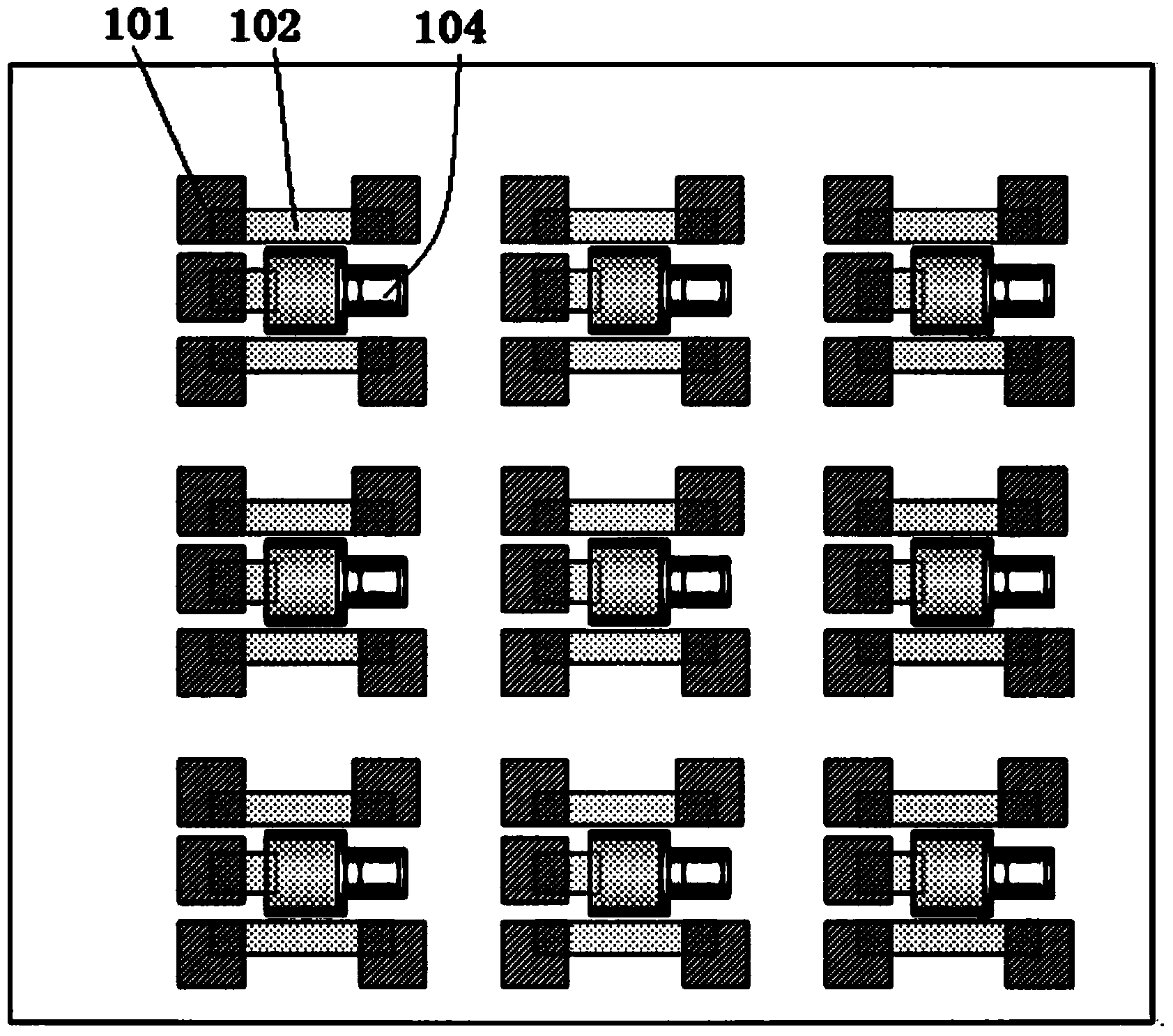

[0029] figure 1 As shown, the film bulk acoustic resonator FBAR used for infrared detection in the present invention includes a metal block 101 , a piezoelectric oscillator stack 108 and an acoustic reflection layer 109 thereunder. Wherein, the piezoelectric oscillator stack 108 includes a bottom electrode 104 , a piezoelectric layer 103 , and an upper electrode 102 ; the acoustic wave reflection layer 109 includes a substrate 107 , a support layer 105 , and an air cavity 106 .

[0030] The FBAR vibration mode can be a shear wave mode, a shear wave mode, or a mixed mode of the two. Different vibration modes correspond to the electrode distri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com