A nickel-based alloy ultra-high temperature enamel coating and its preparation method

A nickel-based alloy, ultra-high temperature technology, applied in the field of high temperature enamel coating, can solve the problems of low thermal expansion coefficient, poor thermal shock resistance and low oxidation resistance temperature of enamel coating, and achieve high softening point and thermal shock resistance. Good, high temperature anti-oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

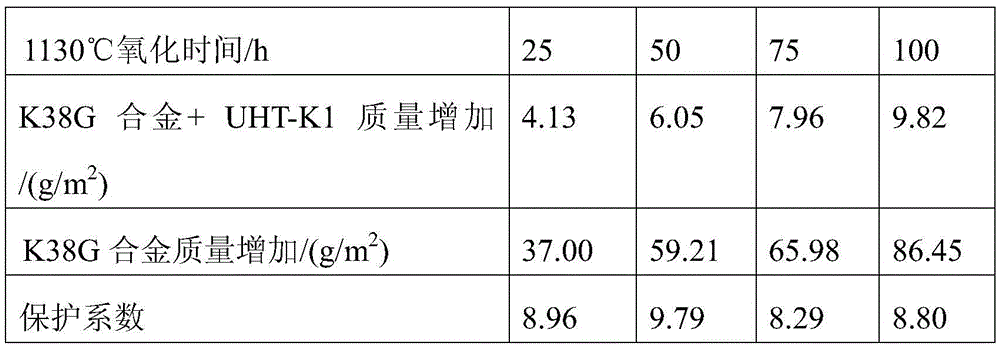

Embodiment 1

[0020] In the K38G alloy ultra-high temperature enamel coating of this embodiment, the enamel slurry is composed of the following components by mass: glass frit: 60, alumina-titanium oxide composite ceramic material: 40, kaolin: 6, water: 70.

[0021] The glass frit of the present embodiment is made up of the component of following mass percent: SiO 2 : 42, BaO: 42, CaO: 4, TiO 2 :3, ZnO: 3, CeO 2 :2,CoO:2,K 2 O: 2.

[0022] The molar ratio of the chemical composition of the alumina-titanium oxide composite ceramic material in this embodiment is 1:1.

[0023] The preparation method of the K38G alloy ultra-high temperature enamel coating of the present embodiment is:

[0024] Step 1, sintering alumina and titania with a molar ratio of 1:1 to prepare composite ceramics, pulverizing and grinding to obtain alumina and titania composite ceramic materials with an average particle size of 9.0 μm and a purity of 99.92%;

[0025] Step 2, glass frit (SiO 2 Particle size 8.5μm, pur...

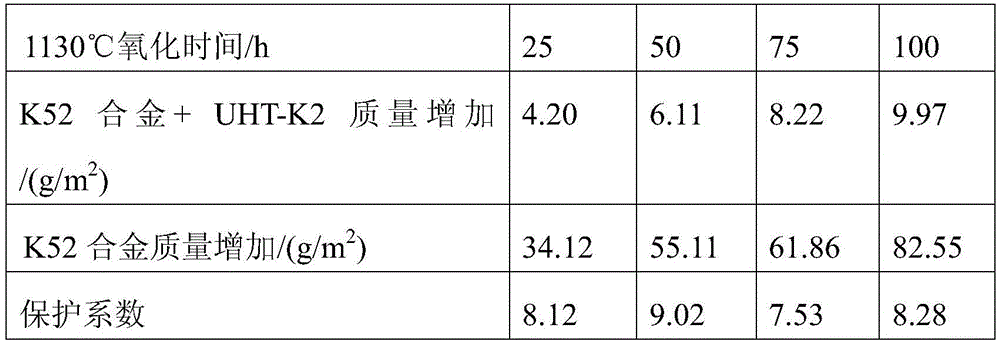

Embodiment 2

[0036] For the K52 alloy ultra-high temperature enamel coating in this embodiment, the enamel slurry is composed of the following components by mass: glass frit: 65, alumina-titanium oxide multi-phase ceramic material: 35, kaolin: 5, water: 65.

[0037] The glass frit of the present embodiment is made up of the component of following mass percent: SiO 2 : 41, BaO: 40, CaO: 5, TiO 2 : 4, ZnO: 3.5, CeO 2 : 3.0, CoO: 1.5, K 2 O: 2.0.

[0038] The molar ratio of the chemical composition of the alumina-titanium oxide composite ceramic material in this embodiment is 1:1.

[0039] The preparation method of the K52 alloy ultra-high temperature enamel coating of the present embodiment is:

[0040] Step 1, sintering alumina and titania with a molar ratio of 1:1 to prepare composite ceramics, pulverizing and grinding to obtain alumina and titania composite ceramic materials with an average particle size of 9.0 μm and a purity of 99.92%;

[0041] Step 2, glass frit (SiO 2 Particle siz...

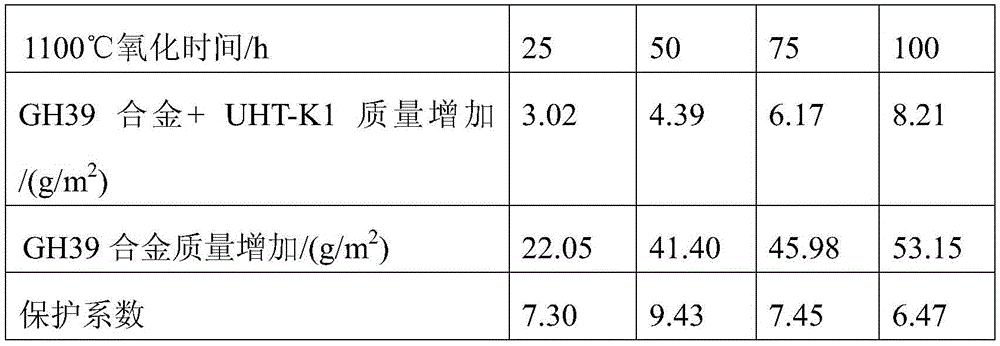

Embodiment 3

[0052] The K407 alloy ultra-high temperature enamel coating of this embodiment is composed of the following components by mass: glass frit: 63, alumina-titanium oxide composite ceramic material: 37, kaolin: 4, water: 67.

[0053] The glass frit of the present embodiment is made up of the component of following mass percent: SiO 2 : 40, BaO: 40, CaO: 6, TiO 2 : 5, ZnO: 4, CeO 2 : 2, CoO: 1, K 2 O: 2.

[0054] The molar ratio of the chemical composition of the alumina-titanium oxide composite ceramic material in this embodiment is 1:1.

[0055] The preparation method of the K407 alloy ultra-high temperature enamel coating of the present embodiment is:

[0056] Step 1, sintering alumina and titania with a molar ratio of 1:1 to prepare composite ceramics, pulverizing and grinding to obtain alumina and titania composite ceramic materials with an average particle size of 9.0 μm and a purity of 99.92%;

[0057] Step 2, glass frit (SiO 2 Particle size 8.5μm, purity 99.95%, BaO p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Anti-oxidation temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com