Multi-resonance absorption zirconium-doped barium ferrite broadband wave-absorbing material and preparation method thereof

A technology of barium ferrite and wave-absorbing materials, which is applied in the field of multi-resonance absorbing barium ferrite wave-absorbing materials and its preparation, can solve the problems of broadening the wave-absorbing frequency band and the inability to further widen the bandwidth, and achieve broadening of the absorption frequency wide, reduce the magnetic crystal anisotropy field, and have good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

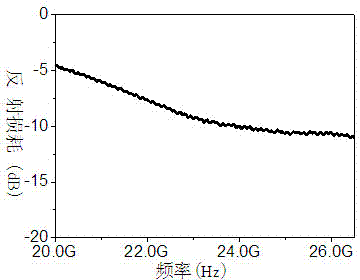

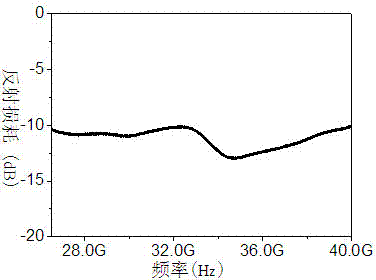

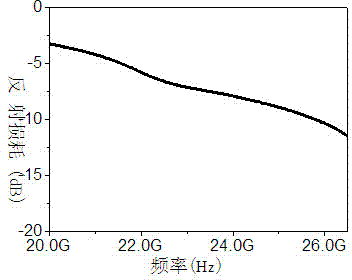

Image

Examples

Embodiment 1

[0031] 1. Preparation of BaFe 11.9 Zr 0.1 O 19

[0032] 1) Mix barium nitrate, zirconium nitrate and ferric nitrate at a molar ratio of 1:0.1:11.9, add deionized water and stir for 3 hours to dissolve to obtain a nitrate solution; the total molar concentration of barium nitrate, ferric nitrate and zirconium nitrate is 1.5 mol / L;

[0033] 2) Put EDTA in deionized water, the molar concentration of EDTA is 0.5mol / L, stir at 80℃ until it is completely dissolved, and then adjust the pH value to 5 with ammonia water to obtain an EDTA solution;

[0034] 3) Add the nitrate solution dropwise to the EDTA solution, the molar ratio of EDTA to the total amount of metal ions in the nitrate solution is 5:1, and continue to heat and stir at 80 ℃ to obtain a sol; dry the resulting sol at 100 ℃, Get fluffy dry gel;

[0035] 4) Finally, put the dry gel in a muffle furnace at 230℃ for 4.5h, then at a rate of 3℃ / min to 460℃ for 4.5h, and then at a rate of 5℃ / min to 600℃ for 4.5h h, then heat up at a rat...

Embodiment 2

[0045] 1. Preparation of BaFe 11.8 Zr 0.2 O 19

[0046] 1) Mix barium nitrate, zirconium nitrate and ferric nitrate at a molar ratio of 1:0.2:11.8, add deionized water and stir for 3.5 hours to dissolve to obtain a nitrate solution; the total molar concentration of barium nitrate, ferric nitrate and zirconium nitrate is 2.0 mol / L;

[0047] 2) Place EDTA in deionized water, stir at 85°C until it is completely dissolved, the molar concentration of EDTA is 1.0 mol / L, and then adjust the pH value to 6 with ammonia water to obtain an EDTA solution;

[0048] 3) Add the nitrate solution dropwise to the EDTA solution, the molar ratio of EDTA to the total amount of metal ions in the nitrate solution is 5:1, and continue to heat and stir at 85 ℃ to obtain a sol; dry the resulting sol at 140 ℃, Get fluffy dry gel;

[0049] 4) Finally, put the dry gel in a muffle furnace at 240°C for 3 hours, then at a rate of 4°C / min to 470°C for 3 hours, and then at a rate of 10°C / min to 700°C for 3 hours, Th...

Embodiment 3

[0059] 1. Preparation of BaFe 11.8 Zr 0.2 O 19

[0060] 1) Mix barium nitrate, zirconium nitrate and iron nitrate at a molar ratio of 1:0.2:11.8, add deionized water and stir for 4 hours to dissolve to obtain a nitrate solution; the total molar concentration of barium nitrate, iron nitrate and zirconium nitrate is 2.5 mol / L;

[0061] 2) Place EDTA in deionized water, stir at 90°C until it is completely dissolved, the molar concentration of EDTA is 1.5mol / L, and then adjust the pH value to 7 with ammonia water to obtain an EDTA solution;

[0062] 3) Add the nitrate solution dropwise to the EDTA solution, the molar ratio of EDTA to the total amount of metal ions in the nitrate solution is 5:1, and continue to heat and stir at 90 ℃ to obtain a sol; dry the resulting sol at 120 ℃, Get fluffy dry gel;

[0063] 4) Finally, put the dry gel in a muffle furnace at 250°C for 1.5 hours, then heat up to 480°C at a rate of 5°C / min for 1.5 hours, and then at a rate of 10°C / min to 800°C for 1.5 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com