Hollow nitrogen-doped nickel oxide/nickel/carbon composite material, preparation method and application

A carbon composite material, nitrogen doping technology, applied in the fields of magnetic field/electric field shielding, electrical components, etc., can solve the problems of unsuitable mass preparation, complex process, cumbersome process, etc., to improve the material utilization rate and increase the composite interface. , the effect of improving the preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

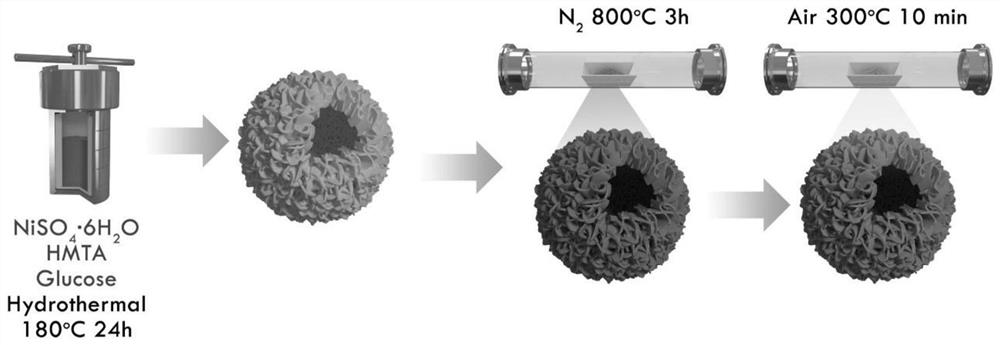

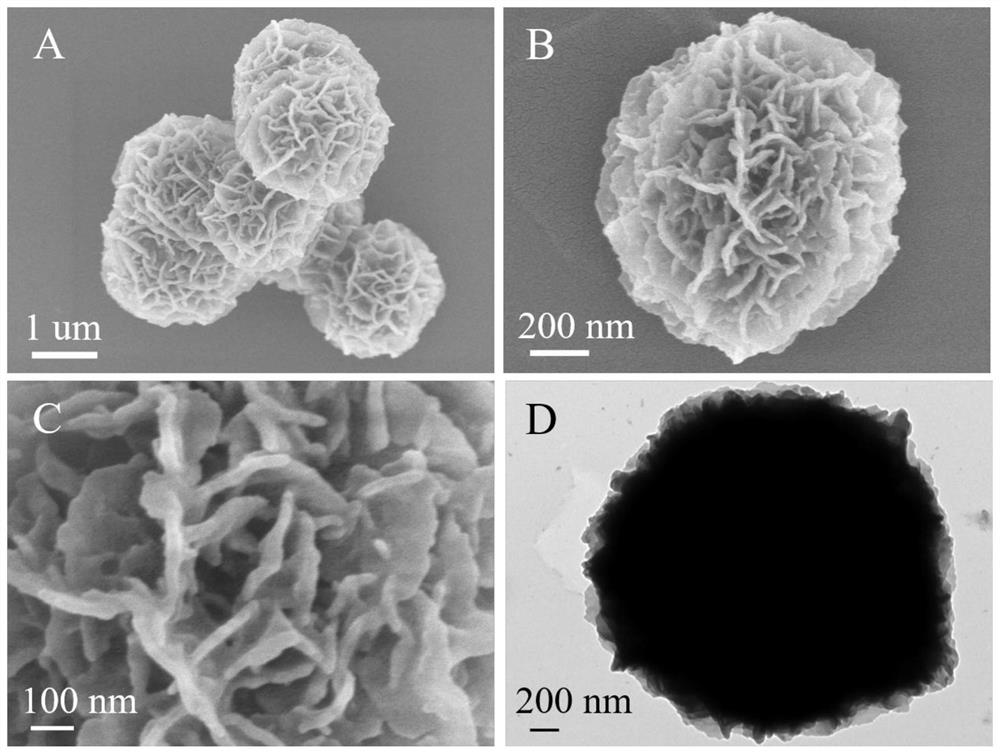

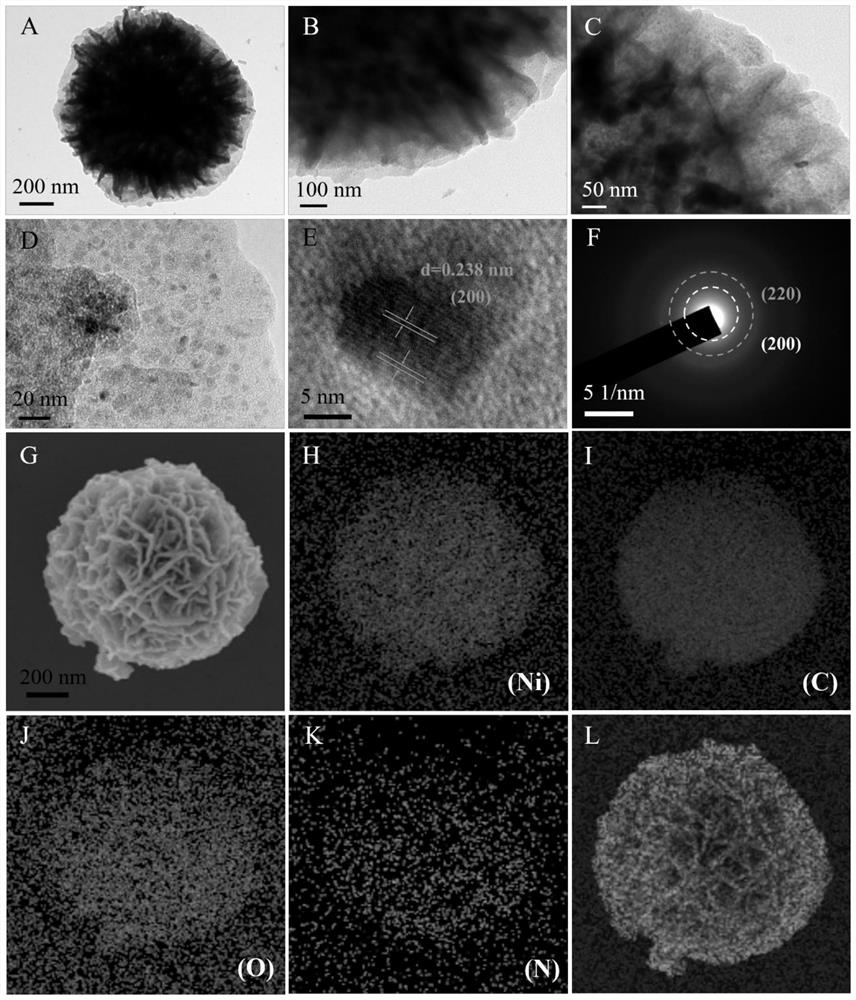

[0031] A preparation method of hollow flower-shaped nitrogen-doped nickel oxide / nickel / carbon composite material, see figure 1 shown, including the following steps:

[0032] First, 0.005molNiSO 4 ·6H 2 O, 0.004mol of glucose and 0.005mol of hexamethylenetetramine were sequentially added into 40ml of deionized water, and fully stirred on an electromagnetic stirrer for 30min to obtain a uniform green solution. The solution was then poured into a hydrothermal reaction kettle with a capacity of 50 ml. Put the hydrothermal reaction kettle into the oven and react at 180°C for 24h. After the reaction, use deionized water and ethanol to centrifuge wash (7000rpm, 3min) more than three times. Then put the product into a vacuum drying oven and dry (80°C, 12h) to obtain a brown solid powder nickel / carbon composite (P-Ni / C); the hexamethylenetetramine can be Diamine or hexamethylenetriamine instead;

[0033] in N 2 Under atmosphere, P-Ni / C was sintered at 700°C (heating rate 5°C / min...

Embodiment 2

[0035] A preparation method of hollow flower-shaped nitrogen-doped nickel oxide / nickel / carbon composite material, see figure 1 shown, including the following steps:

[0036] First, 0.005molNiSO 4 ·6H 2O, 0.004mol of glucose and 0.005mol of hexamethylenetetramine were sequentially added into 40ml of deionized water, and fully stirred on an electromagnetic stirrer for 30min to obtain a uniform green solution. The solution was then poured into a hydrothermal reaction kettle with a capacity of 50 ml. Put the hydrothermal reaction kettle into the oven and react at 180°C for 24h. After the reaction, use deionized water and ethanol to centrifuge wash (7000rpm, 3min) more than three times. Then put the product into a vacuum drying oven and dry (80°C, 12h) to obtain a brown solid powder nickel / carbon composite (P-Ni / C); the hexamethylenetetramine can be Diamine or hexamethylenetriamine instead;

[0037] in N 2 Under atmosphere, P-Ni / C was sintered at 800°C (heating rate 5°C / min)...

Embodiment 3

[0039] A preparation method of hollow flower-shaped nitrogen-doped nickel oxide / nickel / carbon composite material, see figure 1 shown, including the following steps:

[0040] First, 0.005molNiSO 4 ·6H 2 O, 0.004mol of glucose and 0.005mol of hexamethylenetetramine were sequentially added into 40ml of deionized water, and fully stirred on an electromagnetic stirrer for 30min to obtain a uniform green solution. The solution was then poured into a hydrothermal reaction kettle with a capacity of 50 ml. Put the hydrothermal reaction kettle into the oven and react at 180°C for 24h. After the reaction, use deionized water and ethanol to centrifuge wash (7000rpm, 3min) more than three times. Then put the product into a vacuum drying oven and dry (80°C, 12h) to obtain a brown solid powder nickel / carbon composite (P-Ni / C); the hexamethylenetetramine can be Diamine or hexamethylenetriamine instead;

[0041] in N 2 Under atmosphere, sinter P-Ni / C at 900°C (heating rate 5°C / min) for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com