High/low-temperature general-purpose hot-melt pressure-sensitive adhesive and preparation method thereof

A hot-melt pressure-sensitive adhesive, general-purpose technology, applied in the direction of adhesives, adhesive types, mineral oil hydrocarbon copolymer adhesives, etc., can solve the problems of large proportion of hot-melt pressure-sensitive adhesives, poor low temperature resistance, etc. Achieve the effect of good viscous strength, stable performance and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Low temperature resistant, high temperature resistant, high and low temperature general-purpose hot-melt pressure-sensitive adhesive and its preparation

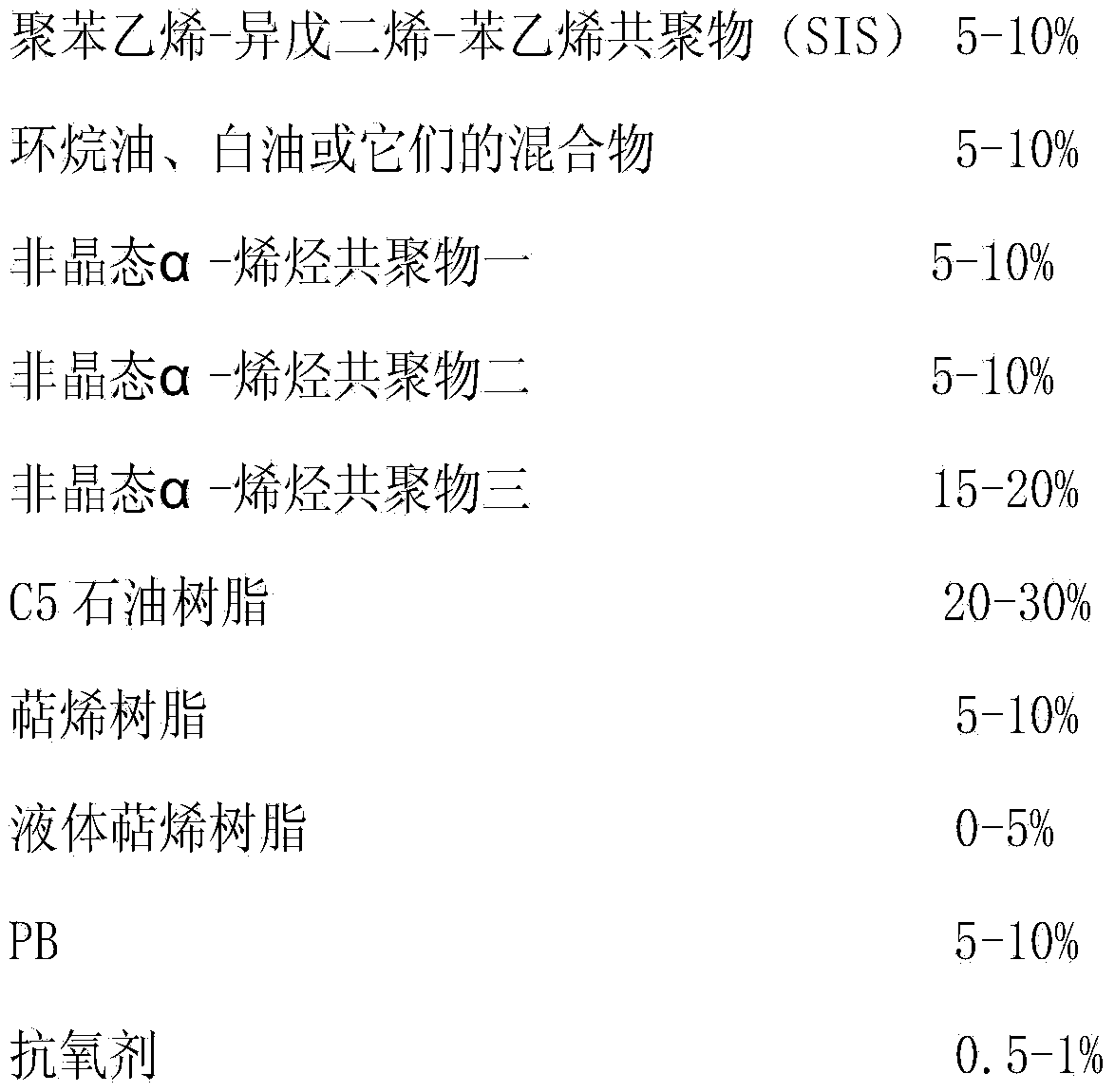

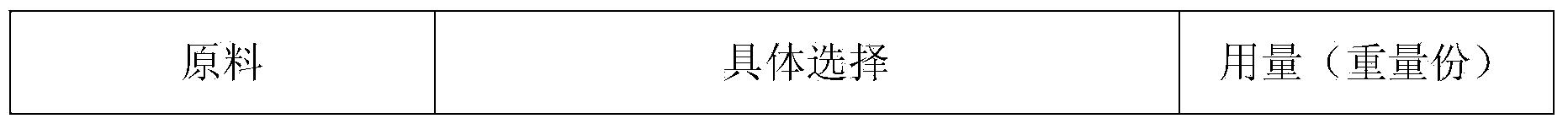

[0028] raw material:

[0029]

[0030]

[0031] Preparation:

[0032] Step 1: Heat naphthenic oil, white oil or their mixture to 140°C, add SIS, wait for it to dissolve, discharge, cool in natural state, and set aside.

[0033] Step 2: Add a small amount of petroleum resin, and after it melts, add amorphous α-olefin copolymer 123 in stages to dissolve it, and control the temperature at 160°C.

[0034] Step 3: Add the spare materials in the first step and stir. After it is fully dissolved, add PB in batches. After it is evenly dissolved, lower the temperature to 140°C, add terpene resin and C5 hydrogenated petroleum resin, and wait for it to melt. Finally, add an antioxidant, heat-preserve and stir for 30 minutes, and discharge to obtain a general-purpose hot-melt pressure-sensitive adhesive with low...

Embodiment 2

[0036] Example 2: Low temperature resistant, high temperature resistant, high and low temperature general-purpose hot-melt pressure-sensitive adhesive and its preparation

[0037] raw material:

[0038]

[0039] Preparation:

[0040] Step 1: Heat naphthenic oil, white oil or their mixture to 160°C, add SIS, wait for it to dissolve, discharge, cool in natural state, and set aside.

[0041] Step 2: Add a small amount of petroleum resin, and after it melts, add amorphous α-olefin copolymer 123 in stages to dissolve it, and control the temperature at 180°C.

[0042] Step 3: Add the spare materials in the first step and stir. After it is fully dissolved, add PB in batches. After it is uniformly dissolved, lower the temperature to 160°C, add terpene resin and C5 hydrogenated petroleum resin, and wait for it to melt. Finally, add an antioxidant, heat-preserve and stir for 30 minutes, and discharge to obtain a general-purpose hot-melt pressure-sensitive adhesive with low temperat...

Embodiment 3

[0044] Example 3: Low temperature resistant, high temperature resistant, high and low temperature general-purpose hot-melt pressure-sensitive adhesive and its preparation

[0045] raw material:

[0046]

[0047]

[0048] Preparation:

[0049] Step 1: Heat naphthenic oil, white oil or their mixture to 140°C, add SIS, wait for it to dissolve, discharge, cool in natural state, and set aside.

[0050] Step 2: Add a small amount of petroleum resin, and after it melts, add amorphous α-olefin copolymer 123 in stages to dissolve it, and control the temperature at 180°C.

[0051] Step 3: Add the spare materials in the first step and stir. After it is fully dissolved, add PB in batches. After it is evenly dissolved, lower the temperature to 140°C, add terpene resin and C5 hydrogenated petroleum resin, and wait for it to melt. Finally, add an antioxidant, heat-preserve and stir for 10 minutes, and discharge to obtain a general-purpose hot-melt pressure-sensitive adhesive with low...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com