Production method of high-toughness microcrystal hard alloys

A technology of cemented carbide and manufacturing method, applied in the field of cemented carbide, can solve the problems of low mixing efficiency, elimination difficulty, uneven mixing, etc., and achieve the effects of reducing the surface roughness of the workpiece, improving the durability, and improving the cutting force of the tool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific embodiment of the present invention is described further below:

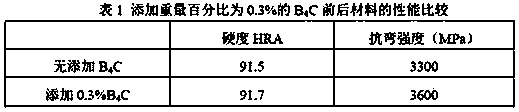

[0013] The process of manufacturing microcrystalline cemented carbide in the present invention is divided into: batching → ball milling → granulation (including sieving and drying, waxing process) → pressing → low pressure sintering (including dewaxing and pre-sintering process), the existing in the present invention The vacuum sintering method is different. The pressed product adopts a low-pressure sintering process, which is sintered in an integrated furnace for dewaxing pre-sintering and low-pressure sintering. The specific process is: charging→vacuumizing→heating to 300~500℃ for dewaxing and pre-sintering →Heating up to 1200°C for heat preservation→Heating up to liquid phase sintering temperature→Filling with Ar to pressurize→Insulation and pressurization→Depressurization and cooling→Unloading. At the same time, in the batching process of the present invention, the HCP value of raw materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com