Film Coating System Capable Of Performing Thin Film Deposition In Rigorous Evaporation Environment

A technology of coating system and evaporation system, which is applied in the field of material deposition, can solve the problems that QCM and thermocouple cannot be used in evaporation coating system, and cannot withstand corrosion and reaction atmosphere, so as to reduce the preparation cost and ensure the uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

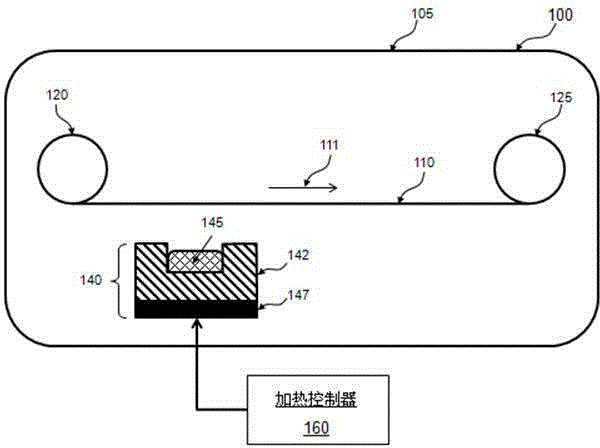

[0020] refer to figure 1 , the coating system 100 includes a vacuum process chamber 105 , and a conveying mechanism built in the chamber is used to move a substrate 110 in a direction 111 . The transport mechanism may include unwind rolls 120 and take-up rolls 125 which may transport a film (or flexible) substrate. The evaporation system 140 includes a crucible 142 for holding an evaporation material 145 such as copper. The evaporation system further includes a heater 147 for heating the evaporation material 145 in the crucible 142 and vaporizing it. After the process chamber is evacuated, the heater 147 heats the crucible 142 to increase the temperature of the evaporation material 145 above the evaporation point. Vapor consists of atoms and groups of atoms of the vaporized material. The vapor stream is delivered to the substrate 110 and deposits a thin film of evaporated material on the substrate. Moving the substrate by the transport mechanism causes the evaporation mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com