Composite corrosion inhibitor electrolyte, application thereof and magnesium air battery

A composite corrosion inhibitor and air battery technology, which can be used in electrical components, secondary batteries, acid electrolytes, etc., and can solve problems such as poor slow-release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

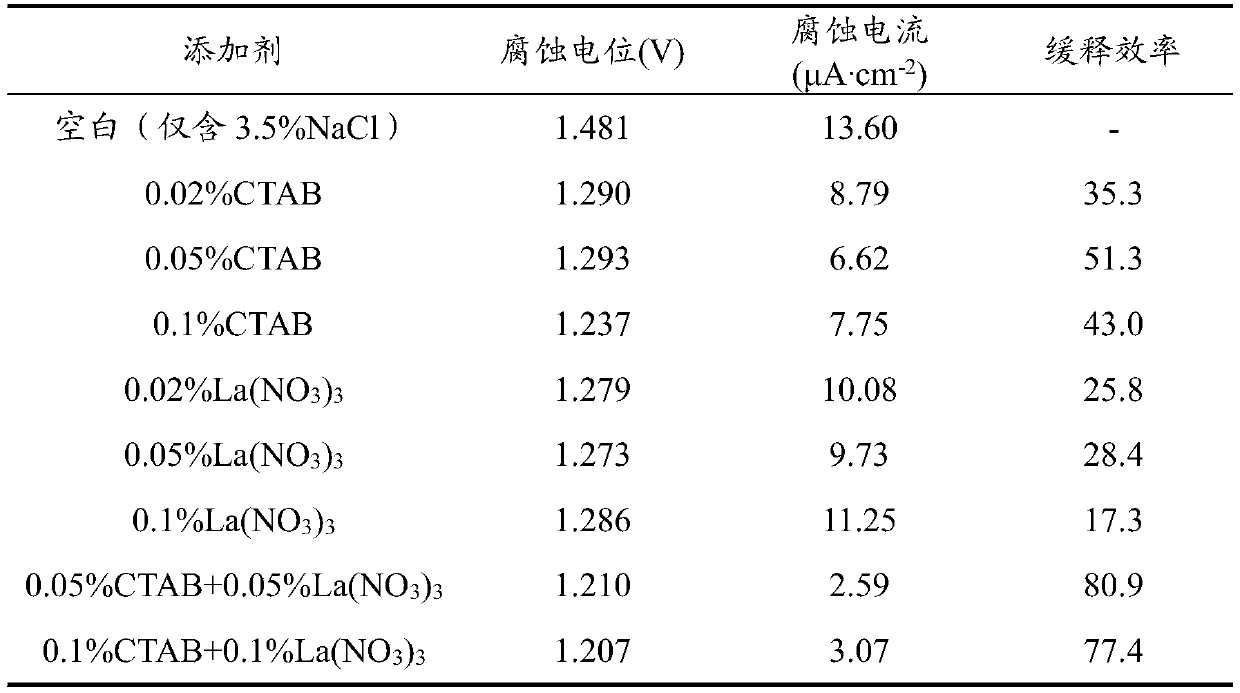

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] In the present invention, there is no special limitation on the preparation method of the composite corrosion inhibitor electrolyte, which can be prepared by a preparation method well known to those skilled in the art.

[0022] The present invention also provides the application of the composite corrosion inhibitor electrolyte described in the above technical solution in a magnesium-air battery.

[0023] The present invention also provides a magnesium-air battery, comprising a negative electrode, an air positive electrode and the composite corrosion inhibitor electrolyte described in the above technical solution, and the negative electrode is a magnesium alloy anode material.

[0024] In the present invention, the magnesium alloy anode material in the magnesium-air battery is preferably cylindrical, and the thickness of the cylindrical shape is preferably 8 mm. In the present invention, the cylinder is preferably polished with 200#, 400# and 800# sandpaper in sequence. ...

Embodiment 1

[0044] (1) Before smelting the alloy, use sandpaper and clean water to clean the oil stains and rust on the surface of the metal raw materials and dry them.

[0045] (2) In the process of smelting metal, first put high-purity magnesium and high-purity aluminum into an alumina crucible, and add magnesium alloy covering agent, the quality of magnesium alloy covering agent is 5% of the weight of high-purity magnesium and high-purity aluminum, magnesium alloy covering The chemical composition of the agent is 45% magnesium chloride, 30% potassium chloride, 10% sodium chloride, 1% calcium chloride, 1% calcium fluoride, 3% magnesium oxide and 10% carbonate foaming agent (CaCO 3 ). Place the crucible in a resistance furnace, heat it to 720°C, and keep it warm for about 25 minutes until it is completely melted.

[0046] (3) Add other alloying elements (indium and erbium) into the crucible, stir evenly with a graphite rod, put it in a furnace at 720°C for 8 minutes, and make it fully d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com